What is Global Substrate Wetting Additives Market?

The Global Substrate Wetting Additives Market is a specialized segment within the broader chemical additives industry, focusing on products that enhance the wetting properties of substrates. These additives are crucial in various applications where the uniform spreading of liquids over surfaces is required. They work by reducing the surface tension between the liquid and the substrate, allowing for better adhesion and coverage. This is particularly important in industries such as paints and coatings, where achieving a smooth, even finish is essential. The market for these additives is driven by the growing demand for high-performance coatings and the need for improved product quality in various end-use industries. As manufacturers strive to meet stringent environmental regulations and consumer expectations, the development of innovative, eco-friendly wetting additives has become a priority. The market is characterized by a diverse range of products, each tailored to specific applications and performance requirements. With advancements in technology and increasing awareness of the benefits of substrate wetting additives, the market is poised for significant growth in the coming years.

Waterborne Systems, Solventborne Systems, Others in the Global Substrate Wetting Additives Market:

Waterborne systems, solventborne systems, and other types of formulations play a pivotal role in the Global Substrate Wetting Additives Market. Waterborne systems are increasingly popular due to their environmental benefits and reduced volatile organic compound (VOC) emissions. These systems use water as the primary solvent, making them more sustainable and less harmful to both the environment and human health. In waterborne systems, substrate wetting additives are essential for improving the flow and leveling properties of coatings, ensuring a smooth and defect-free finish. They help in overcoming the challenges associated with the high surface tension of water, which can hinder the wetting process. Solventborne systems, on the other hand, rely on organic solvents to dissolve the resin and other components of the coating. These systems are known for their excellent performance characteristics, such as durability and resistance to harsh environmental conditions. Substrate wetting additives in solventborne systems are crucial for enhancing the wetting and spreading of the coating on various substrates, ensuring optimal adhesion and finish. Despite the environmental concerns associated with solventborne systems, they remain popular in applications where high performance is a priority. Other types of formulations in the substrate wetting additives market include powder coatings and UV-curable systems. Powder coatings are solvent-free and offer excellent durability and resistance to corrosion and chemicals. Substrate wetting additives in powder coatings help in achieving uniform coverage and smooth finishes. UV-curable systems, which cure upon exposure to ultraviolet light, are gaining traction due to their rapid curing times and minimal environmental impact. In these systems, substrate wetting additives are essential for ensuring proper flow and leveling, as well as enhancing the adhesion of the coating to the substrate. Overall, the choice of system—whether waterborne, solventborne, or other—depends on the specific requirements of the application, including environmental considerations, performance characteristics, and cost-effectiveness. As the demand for high-quality, sustainable coatings continues to grow, the role of substrate wetting additives in these systems will become increasingly important.

Automotive, Construction, Packaging, Electronics, Others in the Global Substrate Wetting Additives Market:

The usage of Global Substrate Wetting Additives Market spans across various industries, including automotive, construction, packaging, electronics, and others, each with its unique set of requirements and challenges. In the automotive industry, substrate wetting additives are crucial for achieving high-quality finishes on vehicles. They enhance the flow and leveling properties of automotive coatings, ensuring a smooth, glossy finish that is resistant to environmental factors such as UV radiation and corrosion. In the construction industry, these additives are used in paints and coatings to improve the adhesion and durability of surfaces exposed to harsh weather conditions. They help in achieving uniform coverage and preventing defects such as blistering and peeling. In the packaging industry, substrate wetting additives are used to enhance the printability and adhesion of inks and coatings on various packaging materials. This is particularly important for maintaining the aesthetic appeal and functionality of packaging products. In the electronics industry, these additives are used in the manufacturing of electronic components and devices to improve the adhesion and performance of coatings and adhesives. They help in achieving precise application and uniform coverage, which is critical for the functionality and reliability of electronic products. Other industries that benefit from substrate wetting additives include textiles, where they are used to improve the dyeing and finishing processes, and the aerospace industry, where they enhance the performance and durability of coatings used on aircraft. Overall, the versatility and effectiveness of substrate wetting additives make them an essential component in a wide range of applications, contributing to improved product quality and performance across various industries.

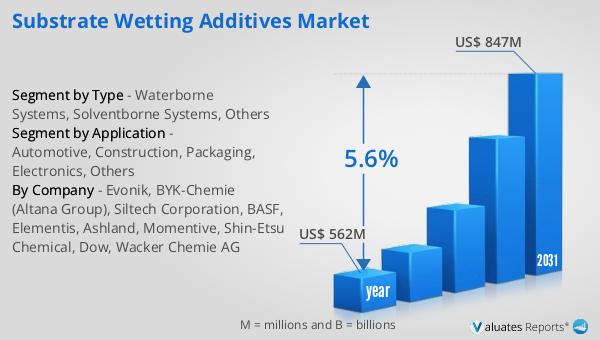

Global Substrate Wetting Additives Market Outlook:

The global market for substrate wetting additives was valued at $562 million in 2024 and is anticipated to expand to a revised size of $847 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth trajectory underscores the increasing demand for substrate wetting additives across various industries, driven by the need for high-performance coatings and improved product quality. The market's expansion is also fueled by advancements in technology and the development of innovative, eco-friendly additives that meet stringent environmental regulations. As industries continue to prioritize sustainability and performance, the demand for substrate wetting additives is expected to rise, contributing to the market's robust growth. The projected increase in market size highlights the significant opportunities for manufacturers and suppliers in the substrate wetting additives industry, as they strive to meet the evolving needs of their customers and capitalize on the growing demand for high-quality, sustainable products.

| Report Metric | Details |

| Report Name | Substrate Wetting Additives Market |

| Accounted market size in year | US$ 562 million |

| Forecasted market size in 2031 | US$ 847 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Evonik, BYK-Chemie (Altana Group), Siltech Corporation, BASF, Elementis, Ashland, Momentive, Shin-Etsu Chemical, Dow, Wacker Chemie AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |