What is Global Electrostatic Spraying Market?

The Global Electrostatic Spraying Market is a rapidly evolving sector that focuses on the application of electrostatic technology to spray coatings and liquids across various surfaces. This market is driven by the need for efficient, uniform, and environmentally friendly spraying solutions. Electrostatic spraying involves charging particles of the spray material, which are then attracted to the surface being coated, ensuring a more even and complete coverage. This technology is widely used in industries such as automotive, electronics, and agriculture, among others. The market is characterized by continuous innovation and development, with companies striving to improve the efficiency and effectiveness of their spraying systems. The demand for electrostatic spraying is increasing due to its advantages over traditional spraying methods, such as reduced waste, lower environmental impact, and improved finish quality. As industries continue to seek sustainable and cost-effective solutions, the Global Electrostatic Spraying Market is expected to grow, offering numerous opportunities for businesses and investors alike. The market's growth is also supported by advancements in technology and the increasing adoption of electrostatic spraying in emerging markets. Overall, the Global Electrostatic Spraying Market is poised for significant expansion in the coming years.

Powder Electrostatic Spraying, Liquid Electrostatic Spraying in the Global Electrostatic Spraying Market:

Powder Electrostatic Spraying and Liquid Electrostatic Spraying are two primary methods utilized within the Global Electrostatic Spraying Market, each offering unique benefits and applications. Powder Electrostatic Spraying involves the use of dry powder that is electrostatically charged and sprayed onto a surface. This method is particularly popular in industries where a durable and high-quality finish is required, such as in automotive and industrial equipment manufacturing. The powder particles are charged and adhere to the surface, creating a uniform coating that is then cured under heat to form a hard finish. This process is environmentally friendly as it produces minimal waste and does not require solvents, making it a preferred choice for companies looking to reduce their environmental footprint. On the other hand, Liquid Electrostatic Spraying involves the use of liquid paint or coating materials that are charged and sprayed onto surfaces. This method is widely used in applications where a smooth and glossy finish is desired, such as in the production of appliances and electronics. Liquid electrostatic spraying allows for precise control over the thickness and consistency of the coating, resulting in a high-quality finish that enhances the appearance and durability of the product. Both methods offer significant advantages over traditional spraying techniques, including reduced overspray, improved transfer efficiency, and lower material costs. The choice between powder and liquid electrostatic spraying often depends on the specific requirements of the application, such as the type of material being coated, the desired finish, and environmental considerations. As the Global Electrostatic Spraying Market continues to grow, advancements in technology are expected to further enhance the capabilities and applications of both powder and liquid electrostatic spraying, providing industries with even more efficient and sustainable solutions.

Automotive, Appliances, Furniture, Electronics, Industrial Equipment, Architectural Parts in the Global Electrostatic Spraying Market:

The Global Electrostatic Spraying Market finds extensive usage across various industries, including automotive, appliances, furniture, electronics, industrial equipment, and architectural parts, each benefiting from the unique advantages of electrostatic spraying technology. In the automotive industry, electrostatic spraying is used to apply paint and coatings to vehicles, providing a high-quality finish that is both durable and aesthetically pleasing. The technology ensures even coverage and reduces waste, making it a cost-effective solution for manufacturers. In the appliance industry, electrostatic spraying is used to coat surfaces of products such as refrigerators, washing machines, and ovens, enhancing their appearance and resistance to wear and tear. The furniture industry also benefits from electrostatic spraying, as it allows for the application of coatings that protect and enhance the appearance of wood and metal furniture. In the electronics industry, electrostatic spraying is used to apply coatings to circuit boards and other components, providing protection against moisture and corrosion. Industrial equipment manufacturers use electrostatic spraying to apply durable coatings that protect machinery from harsh environmental conditions and extend their lifespan. Architectural parts, such as window frames and metal facades, are coated using electrostatic spraying to enhance their appearance and resistance to weathering. The technology's ability to provide a uniform and high-quality finish makes it an ideal choice for these applications. As industries continue to seek efficient and sustainable solutions, the Global Electrostatic Spraying Market is expected to see increased adoption across these sectors, driven by the need for high-performance coatings and finishes.

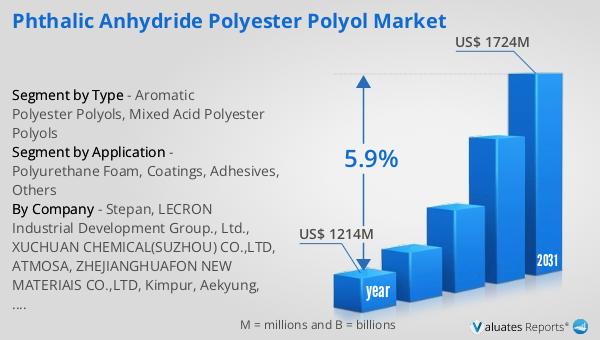

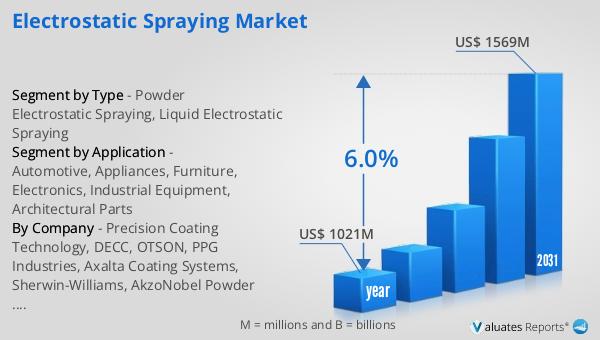

Global Electrostatic Spraying Market Outlook:

The global market for Electrostatic Spraying was valued at $1,021 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $1,569 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.0% over the forecast period. The increasing demand for efficient and environmentally friendly spraying solutions across various industries is a key driver of this market expansion. As industries such as automotive, electronics, and agriculture continue to adopt electrostatic spraying technology, the market is expected to experience robust growth. The advantages of electrostatic spraying, including reduced waste, improved finish quality, and lower environmental impact, are contributing to its increasing popularity. Additionally, advancements in technology and the growing adoption of electrostatic spraying in emerging markets are expected to further fuel market growth. Companies operating in this market are focusing on innovation and development to enhance the efficiency and effectiveness of their spraying systems, providing opportunities for businesses and investors alike. Overall, the Global Electrostatic Spraying Market is poised for significant expansion in the coming years, driven by the increasing demand for sustainable and cost-effective spraying solutions.

| Report Metric | Details |

| Report Name | Electrostatic Spraying Market |

| Accounted market size in year | US$ 1021 million |

| Forecasted market size in 2031 | US$ 1569 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Precision Coating Technology, DECC, OTSON, PPG Industries, Axalta Coating Systems, Sherwin-Williams, AkzoNobel Powder Coatings, Nippon Paint Industrial, Tiger Drylac, Jotun, BASF Coatings, Nordson, BC Paints, Venger Coatings, Electro Painting & Refurbishing INC, Gema Switzerland |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |