What is Global Sensors for Hydrogen Processes Market?

The Global Sensors for Hydrogen Processes Market is a specialized segment within the broader sensor industry, focusing on the development and deployment of sensors specifically designed for hydrogen-related applications. As the world increasingly turns to hydrogen as a clean energy source, the demand for precise and reliable sensors in hydrogen processes has grown significantly. These sensors play a crucial role in ensuring the safety, efficiency, and effectiveness of hydrogen production, storage, and utilization. They are used to monitor various parameters such as gas concentration, pressure, temperature, flow, and levels within hydrogen systems. The market encompasses a wide range of sensor types, each tailored to meet the specific needs of hydrogen applications. With the global push towards sustainable energy solutions, the Global Sensors for Hydrogen Processes Market is poised for substantial growth, driven by technological advancements and increasing investments in hydrogen infrastructure. The market's expansion is further supported by stringent safety regulations and the need for real-time monitoring in hydrogen processes, making these sensors indispensable in the transition to a hydrogen-based economy.

Gas Sensors, Pressure Sensors, Temperature Sensors, Flow Sensors, Level Sensors, Others in the Global Sensors for Hydrogen Processes Market:

Gas sensors are pivotal in the Global Sensors for Hydrogen Processes Market, as they are designed to detect and measure the concentration of hydrogen gas in various environments. These sensors are crucial for safety, as hydrogen is highly flammable and can pose significant risks if not properly monitored. Gas sensors utilize different technologies, such as electrochemical, catalytic, and infrared, to provide accurate readings of hydrogen levels, ensuring that any leaks or abnormal concentrations are quickly identified and addressed. Pressure sensors, on the other hand, are essential for monitoring the pressure within hydrogen systems. They help maintain optimal operating conditions by providing real-time data on pressure levels, which is vital for the safe storage and transportation of hydrogen. These sensors are designed to withstand the high pressures associated with hydrogen applications, ensuring durability and reliability. Temperature sensors are equally important, as they monitor the temperature within hydrogen processes. Accurate temperature readings are crucial for maintaining the efficiency and safety of hydrogen systems, as temperature fluctuations can impact the performance and stability of hydrogen storage and utilization. Flow sensors are used to measure the flow rate of hydrogen gas within pipelines and systems. They provide critical data that helps optimize the distribution and usage of hydrogen, ensuring that it is delivered efficiently and safely to its intended destination. Level sensors, meanwhile, are used to monitor the levels of hydrogen in storage tanks and other containment systems. They provide real-time data on the amount of hydrogen available, helping to prevent overfilling and ensuring that supply meets demand. Other sensors in the market include those designed for specific applications, such as leak detection and system diagnostics. These sensors are integral to the overall safety and efficiency of hydrogen processes, providing the data needed to make informed decisions and maintain optimal operating conditions. As the hydrogen economy continues to grow, the demand for these specialized sensors is expected to increase, driving innovation and development within the Global Sensors for Hydrogen Processes Market.

Hydrogen Production Plants, Hydrogen Refueling Stations, Hydrogen Storage Facilities, Others in the Global Sensors for Hydrogen Processes Market:

The usage of Global Sensors for Hydrogen Processes Market is extensive across various sectors, particularly in hydrogen production plants, hydrogen refueling stations, hydrogen storage facilities, and other related areas. In hydrogen production plants, sensors are used to monitor and control the various processes involved in producing hydrogen. Gas sensors detect hydrogen leaks, ensuring safety and preventing potential hazards. Pressure and temperature sensors help maintain optimal conditions for hydrogen production, ensuring efficiency and quality. Flow sensors monitor the movement of hydrogen through the production system, while level sensors ensure that storage tanks are filled to the correct levels. These sensors work together to optimize production processes, reduce waste, and enhance safety. In hydrogen refueling stations, sensors play a critical role in ensuring the safe and efficient transfer of hydrogen to vehicles. Gas sensors detect any leaks during the refueling process, while pressure sensors ensure that hydrogen is dispensed at the correct pressure. Temperature sensors monitor the temperature of hydrogen to prevent overheating and ensure safe refueling. Flow sensors measure the rate at which hydrogen is dispensed, ensuring that vehicles receive the correct amount of fuel. Level sensors monitor the amount of hydrogen available in storage tanks, ensuring that supply meets demand. In hydrogen storage facilities, sensors are used to monitor the conditions within storage tanks and other containment systems. Gas sensors detect leaks, while pressure and temperature sensors ensure that storage conditions remain within safe limits. Flow sensors monitor the movement of hydrogen into and out of storage, while level sensors provide real-time data on the amount of hydrogen available. These sensors help maintain the integrity of storage systems, ensuring that hydrogen is stored safely and efficiently. Other areas where sensors are used include hydrogen transportation systems, where they monitor the conditions within pipelines and other transport infrastructure. They provide critical data that helps ensure the safe and efficient movement of hydrogen from production sites to end-users. Overall, the Global Sensors for Hydrogen Processes Market plays a vital role in the hydrogen economy, providing the data needed to ensure the safety, efficiency, and effectiveness of hydrogen systems.

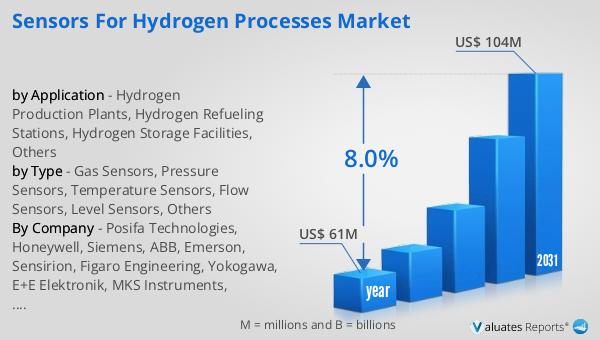

Global Sensors for Hydrogen Processes Market Outlook:

The global market for sensors used in hydrogen processes was valued at approximately 61 million USD in 2024. This market is anticipated to experience significant growth, reaching an estimated size of 104 million USD by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.0% over the forecast period. The increasing demand for hydrogen as a clean energy source is a major driver of this market expansion. As industries and governments worldwide invest in hydrogen infrastructure, the need for reliable and accurate sensors becomes more critical. These sensors are essential for monitoring and controlling hydrogen processes, ensuring safety, and optimizing efficiency. The market's growth is further supported by advancements in sensor technology, which enhance the accuracy and reliability of measurements in hydrogen applications. Additionally, stringent safety regulations and the need for real-time monitoring in hydrogen processes contribute to the increasing demand for these sensors. As the hydrogen economy continues to evolve, the Global Sensors for Hydrogen Processes Market is expected to play a crucial role in supporting the transition to sustainable energy solutions. This market outlook highlights the significant opportunities for growth and innovation within this specialized segment of the sensor industry.

| Report Metric | Details |

| Report Name | Sensors for Hydrogen Processes Market |

| Accounted market size in year | US$ 61 million |

| Forecasted market size in 2031 | US$ 104 million |

| CAGR | 8.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Posifa Technologies, Honeywell, Siemens, ABB, Emerson, Sensirion, Figaro Engineering, Yokogawa, E+E Elektronik, MKS Instruments, Baumer, H2scan, International Gas Detectors Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |