What is Global Online Injection Molding Service Market?

The Global Online Injection Molding Service Market is a dynamic and evolving sector that caters to the needs of various industries by providing custom plastic parts through an online platform. This market leverages the convenience and efficiency of digital platforms to offer injection molding services, which involve the production of plastic components by injecting molten material into a mold. The online aspect of this market allows for streamlined communication, faster turnaround times, and often more competitive pricing compared to traditional methods. Businesses can easily upload their designs, receive instant quotes, and place orders without the need for extensive in-person consultations. This service is particularly beneficial for companies looking to prototype new products or produce small to medium-sized production runs. The global reach of these services means that businesses from different parts of the world can access high-quality injection molding without geographical constraints. As industries continue to innovate and demand more customized solutions, the Global Online Injection Molding Service Market is poised to play a crucial role in meeting these needs efficiently and effectively. The market's growth is driven by advancements in technology, increasing demand for precision-engineered components, and the rising trend of digital transformation across industries.

Horizontal Molding, Insert Molding, Overmolding, Others in the Global Online Injection Molding Service Market:

Horizontal molding, insert molding, overmolding, and other specialized techniques are integral components of the Global Online Injection Molding Service Market, each offering unique benefits and applications. Horizontal molding is the most common type of injection molding process, where the mold opens and closes on a horizontal path. This method is highly efficient for producing a wide range of parts, from simple to complex geometries, and is favored for its speed and cost-effectiveness. It is particularly suitable for high-volume production runs, making it a staple in industries such as automotive and consumer goods. Insert molding, on the other hand, involves the encapsulation of a pre-placed insert, typically made of metal or another material, within the plastic part. This technique is ideal for creating components that require additional strength or functionality, such as threaded inserts or electrical connectors. It allows for the integration of multiple materials into a single part, enhancing the overall performance and durability of the product. Overmolding is a process where a single part is created using two or more different materials, typically by molding a softer material over a rigid substrate. This technique is widely used to improve the ergonomics, aesthetics, and functionality of products, such as adding a soft grip to a tool handle or creating multi-colored components. Overmolding can also provide additional protection to sensitive components, making it a popular choice in the electronics and medical industries. Other specialized techniques in the online injection molding market include micro-molding, which is used for producing extremely small and precise components, and gas-assisted injection molding, which helps in creating hollow parts with reduced weight and material usage. These advanced methods cater to the growing demand for complex and high-performance parts across various sectors. The flexibility and versatility of these molding techniques enable manufacturers to meet specific design requirements and deliver innovative solutions to their customers. As the Global Online Injection Molding Service Market continues to expand, these processes will play a crucial role in driving innovation and meeting the diverse needs of industries worldwide.

Automotive, Consumer Goods, Medical, Aerospace, Electronics, Others in the Global Online Injection Molding Service Market:

The Global Online Injection Molding Service Market finds extensive applications across various industries, including automotive, consumer goods, medical, aerospace, electronics, and others, each benefiting from the unique advantages offered by this manufacturing process. In the automotive industry, injection molding is used to produce a wide range of components, from interior parts like dashboards and door panels to exterior elements such as bumpers and grilles. The precision and repeatability of injection molding make it ideal for producing high-quality, durable parts that meet the stringent safety and performance standards of the automotive sector. In the consumer goods industry, injection molding is employed to manufacture a diverse array of products, from household items and toys to packaging and personal care products. The ability to produce complex shapes and intricate details with high efficiency makes injection molding a preferred choice for consumer goods manufacturers looking to deliver innovative and aesthetically pleasing products to the market. The medical industry also relies heavily on injection molding for the production of medical devices, surgical instruments, and diagnostic equipment. The process ensures the production of sterile, high-precision components that meet the rigorous quality and safety standards required in the medical field. In the aerospace industry, injection molding is used to create lightweight, high-strength components that contribute to the overall efficiency and performance of aircraft. The electronics industry benefits from injection molding by producing components such as connectors, housings, and enclosures that require precise dimensions and intricate designs. The versatility of injection molding allows for the integration of multiple materials and functionalities into a single part, enhancing the performance and reliability of electronic devices. Other industries, such as construction and industrial equipment, also utilize injection molding to produce durable and cost-effective components that meet their specific requirements. The global reach and accessibility of online injection molding services enable businesses across these industries to access high-quality manufacturing solutions without geographical limitations, driving innovation and efficiency in their operations.

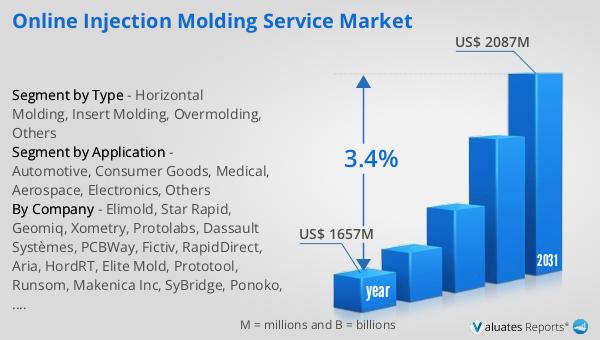

Global Online Injection Molding Service Market Outlook:

In 2024, the global market for Online Injection Molding Service was valued at approximately $1,657 million. Looking ahead, this market is anticipated to grow, reaching an estimated size of $2,087 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.4% over the forecast period. The steady increase in market size reflects the rising demand for efficient and cost-effective manufacturing solutions across various industries. As businesses continue to seek ways to streamline their production processes and reduce costs, the convenience and accessibility of online injection molding services are becoming increasingly attractive. The ability to quickly obtain quotes, place orders, and receive high-quality parts without the need for extensive in-person consultations is a significant advantage for companies looking to innovate and bring new products to market rapidly. Additionally, the global reach of these services allows businesses to access a wide range of materials and expertise, further enhancing their ability to meet specific design and performance requirements. As the market continues to evolve, the focus on digital transformation and the adoption of advanced technologies will likely drive further growth and innovation in the Online Injection Molding Service Market.

| Report Metric | Details |

| Report Name | Online Injection Molding Service Market |

| Accounted market size in year | US$ 1657 million |

| Forecasted market size in 2031 | US$ 2087 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Elimold, Star Rapid, Geomiq, Xometry, Protolabs, Dassault Systèmes, PCBWay, Fictiv, RapidDirect, Aria, HordRT, Elite Mold, Prototool, Runsom, Makenica Inc, SyBridge, Ponoko, ICOMold, Justway, Wikifactory |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |