What is Global Nondestructive Evaluation (NDE) Market?

The Global Nondestructive Evaluation (NDE) Market is a rapidly evolving sector that focuses on techniques used to evaluate the properties of a material, component, or system without causing damage. This market is crucial for industries that require the integrity and reliability of their products, such as aerospace, automotive, and construction. NDE methods are employed to detect flaws, measure geometric characteristics, and determine material properties, ensuring safety and quality. The market encompasses various technologies, including ultrasonic, radiographic, and electromagnetic testing, each offering unique advantages depending on the application. As industries continue to prioritize safety and efficiency, the demand for advanced NDE solutions is expected to grow. The market is driven by technological advancements, increased regulatory standards, and the need for cost-effective testing solutions. Companies in this sector are investing in research and development to innovate and offer more precise and efficient evaluation techniques. The global reach of the NDE market is expanding, with significant growth opportunities in emerging economies where industrialization is on the rise. Overall, the NDE market plays a vital role in maintaining the safety and reliability of critical infrastructure and products across various industries.

X-Rays Type, Ultrasound Type, Infrared Type, Electromagnetic Type, Others in the Global Nondestructive Evaluation (NDE) Market:

In the Global Nondestructive Evaluation (NDE) Market, several types of technologies are employed, each with its unique applications and benefits. X-ray type NDE is widely used for its ability to penetrate materials and reveal internal structures without causing damage. This method is particularly useful in industries like aerospace and automotive, where it is crucial to inspect complex assemblies and detect internal defects. X-rays provide high-resolution images, making them ideal for detailed analysis. However, they require strict safety measures due to radiation exposure. Ultrasound type NDE, on the other hand, uses high-frequency sound waves to detect flaws and measure material thickness. This method is highly effective for inspecting metals, composites, and ceramics. It is non-invasive and safe, making it suitable for a wide range of applications, including pipeline inspection and weld testing. Infrared type NDE involves the use of thermal imaging to detect surface and subsurface defects. It is particularly useful for identifying issues related to heat distribution, such as in electrical systems and building inspections. Infrared technology is non-contact and can cover large areas quickly, making it efficient for routine maintenance checks. Electromagnetic type NDE includes methods like eddy current testing, which is used to detect surface and near-surface defects in conductive materials. This technique is highly sensitive and can be used to inspect complex geometries, such as aircraft components and turbine blades. It is also effective for measuring material thickness and conductivity. Other NDE methods include visual inspection, which is the most basic form of evaluation, and acoustic emission testing, which monitors the release of energy from a material under stress. Each of these technologies offers distinct advantages and is chosen based on the specific requirements of the inspection task. As the NDE market continues to grow, advancements in these technologies are expected to enhance their capabilities, making them more efficient and accurate. Companies are focusing on developing portable and automated NDE solutions to meet the increasing demand for on-site inspections and real-time data analysis. The integration of artificial intelligence and machine learning in NDE technologies is also gaining traction, enabling more precise defect detection and predictive maintenance. Overall, the diverse range of NDE technologies available in the market provides industries with the tools they need to ensure the safety, reliability, and longevity of their products and infrastructure.

Automotive, Aerospace and National Defense, Petroleum and Natural Gas, Infrastructure, Power Generation, Others in the Global Nondestructive Evaluation (NDE) Market:

The Global Nondestructive Evaluation (NDE) Market finds extensive usage across various industries, each with its unique requirements and challenges. In the automotive sector, NDE techniques are employed to ensure the safety and reliability of vehicles. From inspecting welds and joints to evaluating the integrity of critical components like engines and transmissions, NDE plays a crucial role in maintaining quality standards. The use of advanced NDE technologies helps manufacturers detect defects early in the production process, reducing the risk of costly recalls and enhancing customer satisfaction. In the aerospace and national defense industries, NDE is indispensable for ensuring the structural integrity of aircraft and defense equipment. The ability to detect minute flaws in materials and components is vital for preventing catastrophic failures and ensuring the safety of personnel. NDE methods such as ultrasonic and radiographic testing are commonly used to inspect aircraft fuselages, wings, and engines. In the petroleum and natural gas industry, NDE is used to inspect pipelines, storage tanks, and other critical infrastructure. The ability to detect corrosion, cracks, and other defects is essential for preventing leaks and ensuring the safe transport of hazardous materials. NDE techniques such as magnetic particle testing and ultrasonic testing are widely used for pipeline inspection and maintenance. In the infrastructure sector, NDE is used to assess the condition of bridges, buildings, and other structures. The ability to detect structural weaknesses and deterioration is crucial for ensuring public safety and extending the lifespan of infrastructure. NDE methods such as infrared thermography and ground-penetrating radar are commonly used for structural inspections. In the power generation industry, NDE is used to inspect turbines, boilers, and other critical equipment. The ability to detect defects and monitor the condition of equipment is essential for ensuring efficient and reliable power generation. NDE techniques such as eddy current testing and acoustic emission testing are commonly used for equipment inspection and maintenance. Overall, the Global Nondestructive Evaluation (NDE) Market plays a vital role in ensuring the safety, reliability, and efficiency of products and infrastructure across various industries. As industries continue to prioritize safety and quality, the demand for advanced NDE solutions is expected to grow.

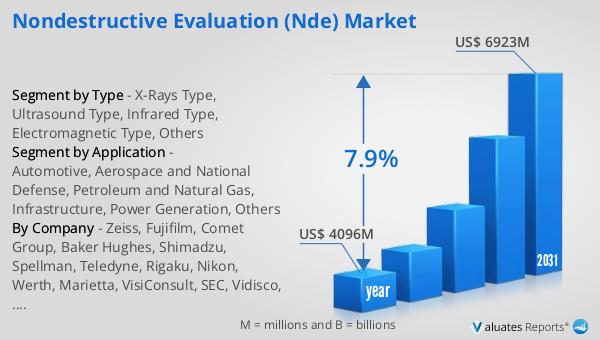

Global Nondestructive Evaluation (NDE) Market Outlook:

The worldwide market for Nondestructive Evaluation (NDE) was estimated to be worth $4,096 million in 2024. It is anticipated to expand to a revised size of $6,923 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.9% over the forecast period. This growth trajectory underscores the increasing importance of NDE technologies across various industries. As industries strive to enhance safety, efficiency, and reliability, the demand for advanced NDE solutions is on the rise. The market's expansion is driven by technological advancements, increased regulatory standards, and the need for cost-effective testing solutions. Companies are investing in research and development to innovate and offer more precise and efficient evaluation techniques. The global reach of the NDE market is expanding, with significant growth opportunities in emerging economies where industrialization is on the rise. Overall, the NDE market plays a vital role in maintaining the safety and reliability of critical infrastructure and products across various industries. As the market continues to grow, advancements in NDE technologies are expected to enhance their capabilities, making them more efficient and accurate. The integration of artificial intelligence and machine learning in NDE technologies is also gaining traction, enabling more precise defect detection and predictive maintenance.

| Report Metric | Details |

| Report Name | Nondestructive Evaluation (NDE) Market |

| Accounted market size in year | US$ 4096 million |

| Forecasted market size in 2031 | US$ 6923 million |

| CAGR | 7.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Zeiss, Fujifilm, Comet Group, Baker Hughes, Shimadzu, Spellman, Teledyne, Rigaku, Nikon, Werth, Marietta, VisiConsult, SEC, Vidisco, QSA Global, Aolong Group, Unicomp Technology, Sanying Precision Instruments, Dandong NDT Equipment, SXRAY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |