What is Global Multi-component Polyurethane Sealant Market?

The Global Multi-component Polyurethane Sealant Market is a specialized segment within the broader sealant industry, focusing on products that are formulated with multiple components to enhance performance characteristics. These sealants are primarily used for their superior adhesion, flexibility, and durability, making them ideal for a variety of applications across different industries. Unlike single-component sealants, multi-component polyurethane sealants require mixing before application, which allows for a more controlled curing process and results in a stronger bond. This market is driven by the increasing demand for high-performance sealants in construction, automotive, and other industrial applications. The versatility of these sealants in bonding diverse materials such as metals, plastics, and glass further boosts their appeal. Additionally, the growing emphasis on sustainable and eco-friendly building practices has led to the development of polyurethane sealants that are low in volatile organic compounds (VOCs), aligning with global environmental standards. As industries continue to seek materials that offer both performance and sustainability, the Global Multi-component Polyurethane Sealant Market is poised for steady growth, supported by technological advancements and expanding application areas.

Non-sagging Type, Self-leveling Type in the Global Multi-component Polyurethane Sealant Market:

In the Global Multi-component Polyurethane Sealant Market, two prominent types of sealants are Non-sagging Type and Self-leveling Type, each catering to specific application needs. Non-sagging polyurethane sealants are designed to stay in place without flowing or sagging, making them ideal for vertical and overhead applications. This characteristic is particularly beneficial in construction projects where sealants are applied to walls or ceilings, ensuring that the material remains in place during the curing process. The non-sagging nature of these sealants is achieved through a carefully balanced formulation that provides the necessary viscosity and thixotropic properties. These sealants are commonly used in building facades, window frames, and other structural joints where a strong, durable bond is required without the risk of the sealant dripping or running. On the other hand, Self-leveling polyurethane sealants are formulated to flow and spread evenly across horizontal surfaces, making them suitable for applications such as flooring, pavements, and expansion joints. The self-leveling property ensures a smooth, even finish, which is crucial for aesthetic and functional purposes. These sealants are often used in areas where a seamless appearance is desired, such as in decorative concrete flooring or tiled surfaces. The ability of self-leveling sealants to fill gaps and voids effectively also makes them a preferred choice for sealing large surface areas. Both types of sealants offer excellent adhesion to a variety of substrates, including concrete, metal, and glass, and are resistant to weathering, UV radiation, and chemical exposure. This makes them suitable for both indoor and outdoor applications, providing long-lasting protection and performance. The choice between non-sagging and self-leveling sealants depends largely on the specific requirements of the project, including the orientation of the surfaces to be sealed and the desired finish. In addition to their primary characteristics, both non-sagging and self-leveling polyurethane sealants offer benefits such as flexibility, which allows them to accommodate movement and thermal expansion in structures. This is particularly important in regions with significant temperature fluctuations, where materials expand and contract with changes in temperature. The flexibility of these sealants helps prevent cracking and ensures the integrity of the seal over time. Furthermore, advancements in formulation technology have led to the development of polyurethane sealants with enhanced properties, such as increased resistance to abrasion and improved adhesion to difficult substrates. These innovations have expanded the range of applications for both non-sagging and self-leveling sealants, making them versatile solutions for modern construction and industrial needs. As the demand for high-performance sealants continues to grow, manufacturers are investing in research and development to create products that meet the evolving needs of the market. This includes the development of sealants with faster curing times, improved environmental profiles, and enhanced performance characteristics. The Global Multi-component Polyurethane Sealant Market is thus characterized by a dynamic landscape, driven by innovation and the pursuit of excellence in sealant technology.

Building Construction, Car Manufacturer, Glass Installation, Electronic Cans, Others in the Global Multi-component Polyurethane Sealant Market:

The usage of Global Multi-component Polyurethane Sealant Market products spans several key areas, including Building Construction, Car Manufacturing, Glass Installation, Electronic Cans, and others. In Building Construction, these sealants are indispensable for ensuring the structural integrity and longevity of buildings. They are used to seal joints and gaps in walls, floors, and ceilings, providing a barrier against moisture, air, and dust infiltration. This not only enhances the energy efficiency of buildings but also contributes to indoor air quality by preventing the ingress of pollutants. The flexibility and durability of polyurethane sealants make them ideal for accommodating the movement and settling of building materials, reducing the risk of cracks and leaks. In Car Manufacturing, multi-component polyurethane sealants play a crucial role in vehicle assembly and maintenance. They are used to bond and seal various components, including windshields, body panels, and interior trim. The strong adhesion and resistance to vibration and temperature fluctuations offered by these sealants ensure the safety and comfort of passengers. Additionally, their ability to reduce noise and vibration enhances the overall driving experience. In Glass Installation, polyurethane sealants provide a secure and weatherproof bond between glass panes and frames. This is essential for both residential and commercial glazing applications, where the sealant must withstand environmental stresses such as wind, rain, and temperature changes. The clarity and UV resistance of these sealants also contribute to the aesthetic appeal and longevity of glass installations. In the realm of Electronic Cans, polyurethane sealants are used to protect sensitive electronic components from moisture, dust, and other environmental factors. Their insulating properties and resistance to chemicals make them suitable for sealing electronic enclosures and connectors, ensuring the reliability and performance of electronic devices. Beyond these specific applications, multi-component polyurethane sealants find use in a variety of other industries, including aerospace, marine, and energy. Their versatility and performance characteristics make them a preferred choice for sealing and bonding applications in demanding environments. As industries continue to evolve and seek materials that offer both performance and sustainability, the usage of multi-component polyurethane sealants is expected to expand, driven by ongoing innovation and the development of new application areas.

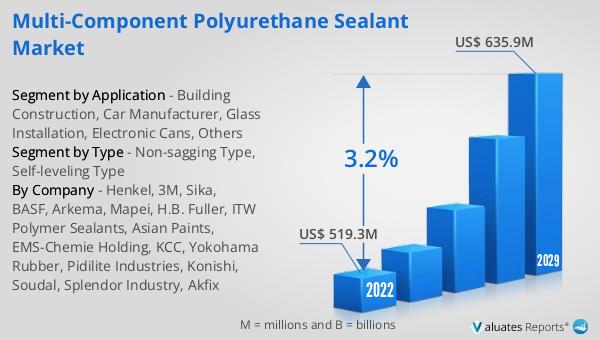

Global Multi-component Polyurethane Sealant Market Outlook:

The global market for Multicomponent Polyurethane Sealant was valued at $542 million in 2024 and is anticipated to grow to a revised size of $673 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.2% during the forecast period. This growth trajectory underscores the increasing demand for high-performance sealants across various industries. The market's expansion is fueled by the rising need for durable and flexible sealing solutions in construction, automotive, and other industrial applications. As industries prioritize sustainability and performance, the demand for polyurethane sealants that offer low VOC emissions and enhanced environmental profiles is expected to rise. The market's growth is also supported by technological advancements in sealant formulations, which have led to the development of products with improved adhesion, faster curing times, and enhanced resistance to environmental factors. These innovations have broadened the scope of applications for polyurethane sealants, making them a versatile choice for modern construction and industrial needs. As the market continues to evolve, manufacturers are investing in research and development to create products that meet the changing demands of consumers and industries. This dynamic landscape presents opportunities for growth and innovation in the Global Multi-component Polyurethane Sealant Market.

| Report Metric | Details |

| Report Name | Multi-component Polyurethane Sealant Market |

| Accounted market size in year | US$ 542 million |

| Forecasted market size in 2031 | US$ 673 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henkel, 3M, Sika, BASF, Arkema, Mapei, H.B. Fuller, ITW Polymer Sealants, Asian Paints, EMS-Chemie Holding, KCC, Yokohama Rubber, Pidilite Industries, Konishi, Soudal, Splendor Industry, Akfix |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |