What is Global LED Display Potting Glue Market?

The Global LED Display Potting Glue Market is a specialized segment within the broader electronics and adhesives industry. This market focuses on the production and distribution of potting compounds specifically designed for LED displays. Potting glue is a crucial component in the manufacturing of LED displays as it provides protection against environmental factors such as moisture, dust, and mechanical stress. These compounds are used to encapsulate the electronic components of LED displays, ensuring their longevity and reliability. The market is driven by the increasing demand for LED displays in various applications, including commercial advertising, home entertainment, and public information systems. As technology advances, the need for more durable and efficient potting solutions grows, leading to innovations in the types of materials used. The market is characterized by a variety of potting compounds, each offering unique properties to meet specific application requirements. Companies in this market are continually researching and developing new formulations to enhance the performance and sustainability of their products. The Global LED Display Potting Glue Market is expected to grow steadily as the adoption of LED technology continues to rise across different sectors.

Epoxy Resin Potting Compound, Silicone Resin Potting Compound, Polyurethane Potting Compound, Others in the Global LED Display Potting Glue Market:

Epoxy Resin Potting Compound is one of the most commonly used materials in the Global LED Display Potting Glue Market. Known for its excellent adhesion and mechanical properties, epoxy resin provides robust protection for LED components. It is highly resistant to environmental factors such as moisture, chemicals, and temperature fluctuations, making it ideal for outdoor and industrial applications. Epoxy resin potting compounds are also known for their thermal conductivity, which helps in dissipating heat generated by the LED components, thus enhancing their performance and lifespan. However, epoxy resins can be rigid and may not be suitable for applications requiring flexibility. Silicone Resin Potting Compound, on the other hand, offers superior flexibility and is highly resistant to extreme temperatures. This makes it suitable for applications where the LED displays are exposed to harsh environmental conditions. Silicone resins are also known for their excellent electrical insulation properties, which protect the LED components from electrical interference. Additionally, silicone potting compounds are UV resistant, making them ideal for outdoor displays that are exposed to sunlight. Polyurethane Potting Compound is another popular choice in the market, known for its versatility and cost-effectiveness. Polyurethane compounds offer a good balance between flexibility and rigidity, making them suitable for a wide range of applications. They provide excellent protection against moisture and mechanical stress, ensuring the durability of the LED displays. Polyurethane potting compounds are also known for their fast curing times, which can enhance production efficiency. However, they may not offer the same level of thermal resistance as epoxy or silicone resins. Other potting compounds in the market include acrylic and hybrid formulations, which are designed to offer specific properties for niche applications. These compounds are often used in specialized LED displays that require unique performance characteristics. The choice of potting compound depends on various factors, including the specific application requirements, environmental conditions, and cost considerations. Manufacturers in the Global LED Display Potting Glue Market are continually innovating to develop new formulations that meet the evolving needs of the industry. As the demand for LED displays continues to grow, the market for potting compounds is expected to expand, driven by advancements in material science and technology.

Commercial Display, Home Display in the Global LED Display Potting Glue Market:

The usage of Global LED Display Potting Glue Market in commercial and home display applications is significant, as these compounds play a crucial role in ensuring the reliability and longevity of LED displays. In commercial display applications, LED displays are often used for advertising, digital signage, and public information systems. These displays are typically exposed to harsh environmental conditions, including extreme temperatures, moisture, and UV radiation. Potting compounds such as epoxy, silicone, and polyurethane are used to encapsulate the electronic components of these displays, providing protection against environmental factors and mechanical stress. This ensures that the displays remain functional and reliable, even in challenging conditions. The choice of potting compound depends on the specific requirements of the application, with silicone resins often preferred for their flexibility and UV resistance. In home display applications, LED displays are commonly used in televisions, monitors, and other consumer electronics. These displays require potting compounds that offer excellent thermal management and electrical insulation properties. Epoxy and polyurethane resins are often used in these applications, as they provide the necessary protection while ensuring optimal performance of the LED components. The potting compounds help in dissipating heat generated by the LED components, preventing overheating and extending the lifespan of the displays. Additionally, the potting compounds protect the electronic components from dust and moisture, ensuring the reliability of the displays in various home environments. As the demand for high-quality LED displays continues to grow in both commercial and home applications, the Global LED Display Potting Glue Market is expected to expand, driven by advancements in potting technology and materials.

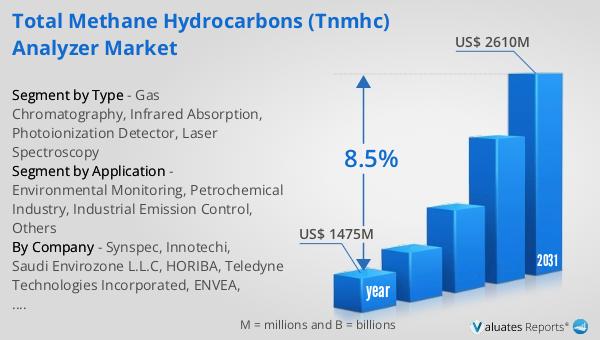

Global LED Display Potting Glue Market Outlook:

The global market for LED Display Potting Glue was valued at approximately USD 1,461 million in 2024. It is anticipated to grow to a revised size of around USD 1,980 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth is indicative of the increasing demand for LED displays across various sectors, including commercial advertising, home entertainment, and public information systems. The market's expansion is driven by the need for more durable and efficient potting solutions that can enhance the performance and longevity of LED displays. As technology continues to advance, manufacturers are focusing on developing new formulations that offer improved protection against environmental factors and mechanical stress. The steady growth of the market is also supported by the rising adoption of LED technology in emerging economies, where the demand for energy-efficient and high-performance displays is on the rise. The Global LED Display Potting Glue Market is expected to continue its upward trajectory as the industry evolves and new applications for LED displays emerge.

| Report Metric | Details |

| Report Name | LED Display Potting Glue Market |

| Accounted market size in year | US$ 1461 million |

| Forecasted market size in 2031 | US$ 1980 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henkel, DOW, Parker, HB Fuller, Novagard Solutions, ELANTAS, Dymax Corporation, Wacker, Shin-Etsu, Xinlun New Materials, Chengdu Tuoli Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |