What is Global Concrete Anti-crack Fiber Market?

The Global Concrete Anti-crack Fiber Market is a specialized segment within the construction industry that focuses on the use of fibers to prevent cracking in concrete structures. Concrete, while strong in compression, is prone to cracking due to its brittle nature and the stresses it undergoes during setting and curing. To address this issue, anti-crack fibers are incorporated into the concrete mix. These fibers help in distributing the stress more evenly across the concrete, thereby reducing the likelihood of cracks forming. The market for these fibers is driven by the increasing demand for durable and long-lasting construction materials. As infrastructure projects around the world continue to grow, the need for concrete that can withstand environmental and mechanical stresses without cracking becomes more critical. The market includes various types of fibers such as steel, glass, polypropylene, and carbon, each offering unique properties that cater to different construction needs. The adoption of these fibers not only enhances the structural integrity of concrete but also extends its lifespan, making it a cost-effective solution for modern construction challenges. As a result, the Global Concrete Anti-crack Fiber Market is witnessing significant growth, driven by technological advancements and the increasing awareness of the benefits of fiber-reinforced concrete.

Steel Fiber, Glass Fiber, Polypropylene Fibers, Carbon Fiber, Others in the Global Concrete Anti-crack Fiber Market:

Steel fiber is one of the most commonly used materials in the Global Concrete Anti-crack Fiber Market. Known for its high tensile strength and durability, steel fiber is often used in applications where enhanced load-bearing capacity and impact resistance are required. It is particularly effective in industrial floors, pavements, and precast concrete products. The incorporation of steel fibers into concrete helps in reducing shrinkage cracks and improving the overall toughness of the structure. Glass fiber, on the other hand, is valued for its lightweight properties and resistance to corrosion. It is often used in architectural applications where aesthetics and durability are equally important. Glass fibers help in reducing the weight of the concrete structure while maintaining its strength, making it ideal for use in facades and decorative elements. Polypropylene fibers are synthetic fibers that are widely used due to their cost-effectiveness and ease of use. They are particularly effective in controlling plastic shrinkage cracks in concrete. These fibers are often used in residential and commercial buildings where cost considerations are paramount. Polypropylene fibers also enhance the freeze-thaw resistance of concrete, making them suitable for use in regions with extreme weather conditions. Carbon fiber, known for its exceptional strength-to-weight ratio, is used in high-performance applications where maximum strength and minimal weight are required. It is often used in bridge construction and other critical infrastructure projects where the structural integrity of the concrete is of utmost importance. Carbon fibers help in reducing the overall weight of the structure while providing superior strength and durability. Other fibers used in the market include natural fibers and hybrid fibers, which combine the properties of different materials to achieve specific performance characteristics. These fibers are used in niche applications where specific requirements need to be met. Overall, the Global Concrete Anti-crack Fiber Market offers a wide range of options for enhancing the performance of concrete, catering to the diverse needs of the construction industry.

Bridge, Rode, Residential, Commercial Building, Others in the Global Concrete Anti-crack Fiber Market:

The usage of Global Concrete Anti-crack Fiber Market in various areas such as bridges, roads, residential, and commercial buildings is extensive and varied. In bridge construction, the use of anti-crack fibers is crucial due to the high load-bearing requirements and exposure to environmental elements. Fibers such as steel and carbon are often used to enhance the tensile strength and durability of the concrete, ensuring that the bridge can withstand heavy traffic and harsh weather conditions without developing cracks. In road construction, anti-crack fibers help in improving the longevity and performance of the pavement. Roads are subject to constant wear and tear due to vehicular traffic and environmental factors. The incorporation of fibers such as polypropylene and steel helps in reducing the formation of cracks and potholes, thereby extending the lifespan of the road and reducing maintenance costs. In residential construction, the use of anti-crack fibers is becoming increasingly popular due to the benefits they offer in terms of durability and cost-effectiveness. Fibers such as polypropylene and glass are often used in residential buildings to control shrinkage cracks and improve the overall quality of the concrete. This not only enhances the aesthetic appeal of the building but also ensures its structural integrity over time. In commercial buildings, where large spans and high load-bearing capacities are often required, the use of fibers such as steel and carbon is common. These fibers help in enhancing the strength and durability of the concrete, making it suitable for use in high-rise buildings and other commercial structures. Other applications of anti-crack fibers include their use in precast concrete products, tunnels, and marine structures, where the prevention of cracks is critical to the performance and longevity of the structure. Overall, the Global Concrete Anti-crack Fiber Market plays a vital role in enhancing the performance and durability of concrete in various construction applications, making it an essential component of modern construction practices.

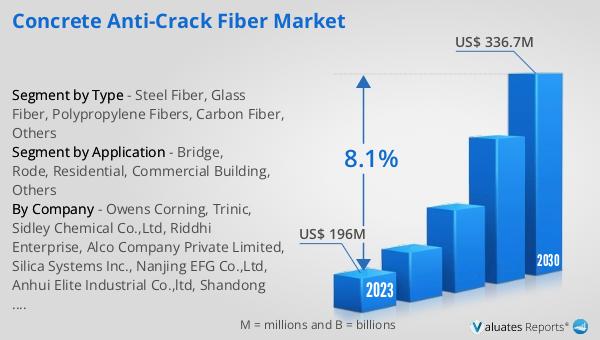

Global Concrete Anti-crack Fiber Market Outlook:

The global market for Concrete Anti-crack Fiber was valued at $226 million in 2024 and is anticipated to expand to a revised size of $388 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.1% during the forecast period. This growth is indicative of the increasing demand for durable and long-lasting construction materials across the globe. As infrastructure development continues to accelerate, particularly in emerging economies, the need for concrete that can withstand environmental and mechanical stresses without cracking becomes more pronounced. The adoption of anti-crack fibers is driven by their ability to enhance the structural integrity and lifespan of concrete, making them a cost-effective solution for modern construction challenges. The market's expansion is further supported by technological advancements and the growing awareness of the benefits of fiber-reinforced concrete. As construction projects become more complex and demanding, the role of anti-crack fibers in ensuring the durability and performance of concrete structures becomes increasingly important. This trend is expected to continue as the construction industry seeks innovative solutions to meet the evolving needs of modern infrastructure development. The projected growth of the Global Concrete Anti-crack Fiber Market underscores the critical role these fibers play in enhancing the performance and longevity of concrete, making them an indispensable component of contemporary construction practices.

| Report Metric | Details |

| Report Name | Concrete Anti-crack Fiber Market |

| Accounted market size in year | US$ 226 million |

| Forecasted market size in 2031 | US$ 388 million |

| CAGR | 8.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Owens Corning, Trinic, Sidley Chemical Co.,Ltd, Riddhi Enterprise, Alco Company Private Limited, Silica Systems Inc., Nanjing EFG Co.,Ltd, Anhui Elite Industrial Co.,ltd, Shandong Jinhongyao Engineering Materials Co., Ltd, Shandong Luke Composite Materials Co., Ltd., Ningbo Shike New Material Technology, Shandong Luxian Building Materials Technology Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |