What is Global CFR Thermoplastic Market?

The Global CFR Thermoplastic Market is a dynamic and evolving sector within the materials industry, characterized by its focus on carbon fiber-reinforced thermoplastics. These materials are known for their exceptional strength-to-weight ratio, making them highly desirable in various high-performance applications. CFR thermoplastics combine carbon fibers with thermoplastic resins, resulting in a composite material that offers superior mechanical properties, such as high tensile strength, stiffness, and impact resistance. These attributes make CFR thermoplastics an attractive choice for industries seeking lightweight yet durable materials. The market is driven by the increasing demand for lightweight materials in sectors like aerospace, automotive, and sports equipment, where reducing weight without compromising strength is crucial. Additionally, the recyclability of thermoplastics compared to thermoset composites adds to their appeal, aligning with the growing emphasis on sustainability. As industries continue to innovate and seek materials that enhance performance while reducing environmental impact, the Global CFR Thermoplastic Market is poised for significant growth, offering new opportunities for manufacturers and end-users alike. The market's expansion is further supported by advancements in manufacturing technologies, which enable more efficient production processes and broader application possibilities.

Continuous Carbon Fiber, Long Carbon Fiber, Short Carbon Fiber in the Global CFR Thermoplastic Market:

Continuous Carbon Fiber, Long Carbon Fiber, and Short Carbon Fiber are three distinct types of carbon fibers used in the Global CFR Thermoplastic Market, each offering unique properties and applications. Continuous Carbon Fiber is characterized by its long, unbroken strands, which provide exceptional strength and stiffness. This type of carbon fiber is often used in applications where maximum structural integrity is required, such as in aerospace components and high-performance automotive parts. The continuous nature of the fibers allows for the creation of composites with superior load-bearing capabilities, making them ideal for critical applications where safety and performance are paramount. Long Carbon Fiber, on the other hand, consists of fibers that are longer than those found in short fiber composites but not as continuous as those in continuous fiber composites. Long carbon fibers offer a balance between strength and processability, making them suitable for applications that require good mechanical properties but also benefit from easier manufacturing processes. These fibers are often used in automotive parts, sporting goods, and industrial equipment, where they provide enhanced performance without the complexity of handling continuous fibers. Short Carbon Fiber is composed of chopped fibers that are typically less than a few millimeters in length. While they do not offer the same level of strength as continuous or long fibers, short carbon fibers are advantageous in applications where complex shapes and intricate designs are required. The shorter fibers allow for easier molding and processing, making them ideal for consumer electronics, small automotive components, and other applications where intricate designs are necessary. Despite their lower strength compared to longer fibers, short carbon fibers still provide significant improvements in mechanical properties over traditional materials, making them a valuable component in the CFR thermoplastic market. Each type of carbon fiber brings its own set of advantages and challenges, and the choice between them depends on the specific requirements of the application, including factors such as strength, weight, cost, and manufacturing complexity. As the Global CFR Thermoplastic Market continues to grow, the demand for these different types of carbon fibers is expected to increase, driven by the need for innovative materials that meet the evolving demands of various industries.

Aerospace, Automotive, Equipment, Sports Equipment, Others in the Global CFR Thermoplastic Market:

The Global CFR Thermoplastic Market finds extensive usage across several key industries, including aerospace, automotive, equipment, sports equipment, and others, each benefiting from the unique properties of carbon fiber-reinforced thermoplastics. In the aerospace industry, CFR thermoplastics are highly valued for their lightweight and high-strength characteristics, which contribute to fuel efficiency and performance improvements in aircraft. These materials are used in the production of various aircraft components, such as fuselage sections, wings, and interior parts, where reducing weight without compromising safety is crucial. The ability to withstand high temperatures and resist corrosion further enhances their suitability for aerospace applications. In the automotive sector, CFR thermoplastics are increasingly used to manufacture lightweight components that improve fuel efficiency and reduce emissions. Parts such as body panels, structural components, and interior elements benefit from the strength and durability of carbon fiber composites, allowing for the production of vehicles that are both high-performing and environmentally friendly. The recyclability of thermoplastics also aligns with the automotive industry's push towards sustainability and circular economy practices. Equipment and machinery industries utilize CFR thermoplastics for their excellent mechanical properties and resistance to wear and tear. These materials are used in the production of industrial equipment, machinery components, and tools, where durability and performance are critical. The lightweight nature of CFR thermoplastics also contributes to easier handling and installation, reducing labor costs and improving efficiency. In the sports equipment industry, CFR thermoplastics are used to create high-performance gear that enhances athletic performance. Items such as bicycles, tennis rackets, golf clubs, and protective gear benefit from the lightweight and strong nature of carbon fiber composites, providing athletes with equipment that improves speed, agility, and safety. Other industries, including consumer electronics and construction, also leverage the advantages of CFR thermoplastics for various applications, from lightweight casings and housings to structural components in buildings and infrastructure. The versatility and adaptability of CFR thermoplastics make them a valuable material across a wide range of sectors, driving innovation and performance improvements in numerous applications.

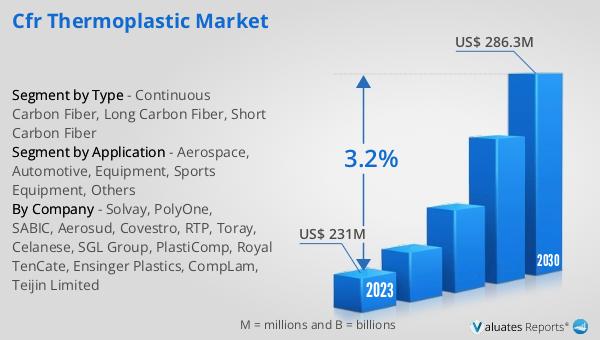

Global CFR Thermoplastic Market Outlook:

The global market for CFR Thermoplastic was valued at $244 million in 2024, and it is anticipated to grow to a revised size of $303 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.2% over the forecast period. This growth trajectory underscores the increasing demand for carbon fiber-reinforced thermoplastics across various industries. The market's expansion is driven by the rising need for lightweight, high-strength materials that offer both performance and sustainability benefits. As industries such as aerospace, automotive, and sports equipment continue to seek materials that enhance efficiency and reduce environmental impact, CFR thermoplastics are becoming an integral part of their material strategies. The projected growth also highlights the advancements in manufacturing technologies that enable more efficient production processes, making these materials more accessible and cost-effective for a broader range of applications. The market's positive outlook is further supported by the growing emphasis on sustainability and recyclability, as thermoplastics offer advantages over traditional thermoset composites in terms of end-of-life disposal and recycling. As the Global CFR Thermoplastic Market continues to evolve, it presents significant opportunities for manufacturers, suppliers, and end-users to capitalize on the benefits of these advanced materials, driving innovation and growth across multiple sectors.

| Report Metric | Details |

| Report Name | CFR Thermoplastic Market |

| Accounted market size in year | US$ 244 million |

| Forecasted market size in 2031 | US$ 303 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Solvay, PolyOne, SABIC, Aerosud, Covestro, RTP, Toray, Celanese, SGL Group, PlastiComp, Royal TenCate, Ensinger Plastics, CompLam, Teijin Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |