What is Global Composite Tooling Prepregs Market?

The Global Composite Tooling Prepregs Market is a specialized segment within the broader composite materials industry, focusing on the production and application of prepregs used in tooling. Prepregs are pre-impregnated composite fibers where a matrix material, such as epoxy, is already present. This market is crucial because it provides the materials necessary for creating molds and tools that are used in manufacturing various composite parts. These tooling prepregs are essential for industries that require high precision and durability, such as aerospace, automotive, and wind energy. The market is driven by the increasing demand for lightweight and high-strength materials, which are essential for improving fuel efficiency and reducing emissions in transportation sectors. Additionally, the growth in renewable energy projects, particularly wind energy, has further fueled the demand for composite tooling prepregs. The market is characterized by continuous innovation, with manufacturers focusing on developing prepregs that offer better performance, ease of use, and cost-effectiveness. As industries continue to seek advanced materials to enhance their products and processes, the Global Composite Tooling Prepregs Market is expected to play a pivotal role in meeting these evolving needs.

Carbon Fiber Prepregs, Glass Fiber Prepregs, Aramid Fiber-Reinforced Plastics, Others in the Global Composite Tooling Prepregs Market:

Carbon Fiber Prepregs are a significant component of the Global Composite Tooling Prepregs Market. These prepregs are made by impregnating carbon fibers with a resin matrix, typically epoxy. Carbon fiber prepregs are renowned for their exceptional strength-to-weight ratio, making them ideal for applications where weight reduction is crucial without compromising strength. They are extensively used in the aerospace industry for manufacturing aircraft components, as well as in the automotive sector for high-performance vehicles. The demand for carbon fiber prepregs is driven by the need for lightweight materials that enhance fuel efficiency and reduce emissions. Glass Fiber Prepregs, on the other hand, are made by impregnating glass fibers with a resin matrix. These prepregs are known for their excellent corrosion resistance, electrical insulation properties, and cost-effectiveness. Glass fiber prepregs are widely used in the construction and marine industries, where durability and resistance to harsh environmental conditions are essential. They are also used in the production of wind turbine blades, contributing to the growth of renewable energy sources. Aramid Fiber-Reinforced Plastics are another important category within the composite tooling prepregs market. Aramid fibers, such as Kevlar, are known for their high impact resistance and thermal stability. These properties make aramid fiber-reinforced plastics suitable for applications in the defense and aerospace industries, where materials must withstand extreme conditions. Additionally, aramid fibers are used in the production of protective gear and equipment, further expanding their market presence. Other types of composite tooling prepregs include those made from hybrid fibers, which combine different types of fibers to achieve specific performance characteristics. These hybrid prepregs offer a balance of properties, such as strength, flexibility, and thermal resistance, making them suitable for a wide range of applications. The Global Composite Tooling Prepregs Market is characterized by a diverse range of materials, each offering unique advantages that cater to the specific needs of various industries. As technology advances and industries continue to seek innovative solutions, the demand for these specialized prepregs is expected to grow, driving further developments in the market.

Automotive, Manufacturing, Aerospace, Wind Energy, Others in the Global Composite Tooling Prepregs Market:

The usage of Global Composite Tooling Prepregs Market spans several key industries, each benefiting from the unique properties of these advanced materials. In the automotive industry, composite tooling prepregs are used to manufacture lightweight and high-strength components, such as body panels, chassis, and interior parts. The use of prepregs in automotive manufacturing helps reduce the overall weight of vehicles, leading to improved fuel efficiency and reduced emissions. This is particularly important as the industry shifts towards electric and hybrid vehicles, where weight reduction is crucial for maximizing battery life and performance. In the manufacturing sector, composite tooling prepregs are used to create molds and tools for producing complex parts with high precision. The ability to produce intricate shapes and designs with minimal waste makes prepregs an attractive option for manufacturers looking to optimize their production processes. In the aerospace industry, composite tooling prepregs are essential for producing lightweight and durable components that can withstand the extreme conditions of flight. The use of prepregs in aircraft manufacturing helps improve fuel efficiency and reduce maintenance costs, contributing to the overall sustainability of the industry. The wind energy sector also relies heavily on composite tooling prepregs for the production of wind turbine blades. The lightweight and high-strength properties of prepregs make them ideal for creating large, efficient blades that can capture more wind energy. This is crucial for the growth of renewable energy sources, as it helps increase the efficiency and output of wind farms. Other industries, such as marine and construction, also benefit from the use of composite tooling prepregs. In the marine industry, prepregs are used to produce lightweight and corrosion-resistant components for boats and ships, enhancing their performance and longevity. In construction, prepregs are used to create durable and weather-resistant materials for building structures, contributing to the development of sustainable and resilient infrastructure. Overall, the Global Composite Tooling Prepregs Market plays a vital role in supporting the advancement of various industries by providing materials that offer superior performance, efficiency, and sustainability.

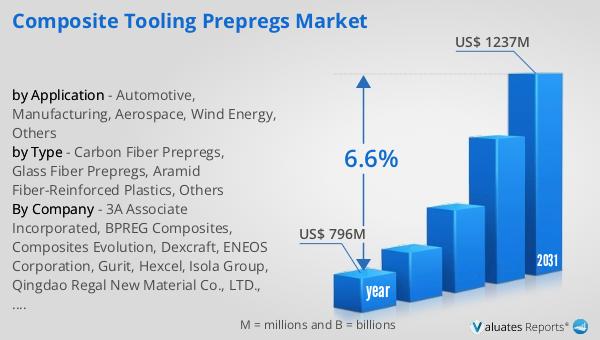

Global Composite Tooling Prepregs Market Outlook:

The global market for Composite Tooling Prepregs was valued at $796 million in 2024 and is anticipated to grow significantly, reaching an estimated value of $1,237 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.6% over the forecast period. This upward trajectory highlights the increasing demand for composite tooling prepregs across various industries, driven by the need for lightweight, high-strength materials that enhance performance and efficiency. The market's expansion is fueled by advancements in technology and the continuous development of innovative prepreg materials that cater to the evolving needs of industries such as aerospace, automotive, and renewable energy. As these industries strive to improve sustainability and reduce environmental impact, the demand for composite tooling prepregs is expected to rise, further driving market growth. The projected increase in market size reflects the growing recognition of the benefits offered by composite tooling prepregs, including their ability to reduce weight, improve fuel efficiency, and enhance the overall performance of products. As a result, the Global Composite Tooling Prepregs Market is poised for significant growth, offering numerous opportunities for manufacturers and suppliers to capitalize on the increasing demand for advanced composite materials.

| Report Metric | Details |

| Report Name | Composite Tooling Prepregs Market |

| Accounted market size in year | US$ 796 million |

| Forecasted market size in 2031 | US$ 1237 million |

| CAGR | 6.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3A Associate Incorporated, BPREG Composites, Composites Evolution, Dexcraft, ENEOS Corporation, Gurit, Hexcel, Isola Group, Qingdao Regal New Material Co., LTD., Renegade Materials, SEIREN Co., LTD, SHD Composite Materials Ltd, Solvay, TCR Composites, Inc, Toray |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |