What is Global CNC Machine Tool Maintenance Service Market?

The Global CNC Machine Tool Maintenance Service Market is a specialized sector that focuses on the upkeep and repair of CNC (Computer Numerical Control) machines, which are essential in modern manufacturing processes. These machines are used to control complex machinery and tools with precision, making them indispensable in industries such as automotive, aerospace, and electronics. The maintenance service market for these machines ensures that they operate efficiently, minimizing downtime and extending their lifespan. This market includes various services such as regular maintenance, emergency repairs, and other specialized services tailored to the needs of different industries. As technology advances, the demand for CNC machines continues to grow, leading to an increased need for maintenance services to keep these machines running smoothly. The market is characterized by a mix of service providers, ranging from large multinational companies to smaller, specialized firms, all competing to offer the best solutions to their clients. With the global manufacturing sector expanding, the CNC Machine Tool Maintenance Service Market is poised for significant growth, driven by the need for high precision and efficiency in production processes.

Regular Maintenance Service, Emergency Repair Service, Others in the Global CNC Machine Tool Maintenance Service Market:

Regular maintenance service in the Global CNC Machine Tool Maintenance Service Market is crucial for ensuring the longevity and optimal performance of CNC machines. This type of service involves routine inspections, cleaning, lubrication, and adjustments to prevent unexpected breakdowns and maintain the machines' accuracy and efficiency. Regular maintenance helps in identifying potential issues before they escalate into major problems, thereby reducing downtime and repair costs. Service providers often offer customized maintenance plans based on the specific needs of the client, taking into account the type of machines, their usage, and the working environment. These plans may include scheduled visits by technicians, who perform a series of checks and maintenance tasks to ensure the machines are in top condition. Emergency repair service, on the other hand, is designed to address unexpected breakdowns or malfunctions that can occur despite regular maintenance. These services are critical in minimizing production losses and ensuring that operations can resume as quickly as possible. Service providers typically offer rapid response times, with skilled technicians available to diagnose and fix issues on-site. This may involve replacing faulty components, recalibrating machines, or performing other necessary repairs to restore functionality. In addition to regular maintenance and emergency repairs, the market also includes other services such as retrofitting, upgrading, and training. Retrofitting involves updating older machines with new technology to improve their performance and extend their lifespan. This can be a cost-effective alternative to purchasing new equipment, allowing companies to take advantage of the latest advancements without a significant capital investment. Upgrading services may include installing new software, adding advanced features, or enhancing the machine's capabilities to meet changing production demands. Training services are also an important aspect of the CNC Machine Tool Maintenance Service Market, as they help operators and maintenance personnel understand how to properly use and care for the machines. This can lead to improved efficiency, reduced errors, and a better understanding of how to troubleshoot minor issues before they require professional intervention. Overall, the Global CNC Machine Tool Maintenance Service Market offers a comprehensive range of services designed to support the efficient operation of CNC machines across various industries. By providing regular maintenance, emergency repairs, and other specialized services, this market plays a vital role in ensuring that manufacturing processes remain smooth and uninterrupted.

Manufacturing, Aerospace Industry, Automotive Manufacturing, Others in the Global CNC Machine Tool Maintenance Service Market:

The usage of Global CNC Machine Tool Maintenance Service Market spans across various industries, each with its unique requirements and challenges. In the manufacturing sector, CNC machines are integral to producing a wide range of products, from simple components to complex assemblies. Regular maintenance services ensure that these machines operate at peak efficiency, reducing the risk of costly downtime and maintaining high-quality production standards. In the aerospace industry, precision and reliability are paramount, as the components produced must meet stringent safety and performance criteria. CNC machines are used to manufacture critical parts such as turbine blades, engine components, and structural elements. Maintenance services in this sector focus on ensuring that machines are calibrated to the highest standards, with regular inspections and adjustments to maintain accuracy and prevent defects. The automotive manufacturing industry also relies heavily on CNC machines for producing parts such as engine blocks, transmission components, and body panels. With the industry's emphasis on efficiency and cost-effectiveness, maintenance services play a crucial role in minimizing production disruptions and ensuring that machines are running smoothly. This includes regular maintenance, emergency repairs, and upgrades to keep up with evolving technology and production demands. Other industries, such as electronics, medical devices, and energy, also benefit from the Global CNC Machine Tool Maintenance Service Market. In the electronics industry, CNC machines are used to produce intricate components with high precision, requiring meticulous maintenance to ensure consistent quality. The medical device industry demands the highest levels of accuracy and reliability, as the products manufactured often have life-saving applications. Maintenance services in this sector focus on maintaining the precision and cleanliness of machines to meet regulatory standards. In the energy sector, CNC machines are used to produce components for power generation and distribution, where reliability and efficiency are critical. Overall, the Global CNC Machine Tool Maintenance Service Market provides essential support to a wide range of industries, ensuring that CNC machines operate efficiently and effectively. By offering regular maintenance, emergency repairs, and other specialized services, this market helps companies maintain high production standards, reduce downtime, and adapt to changing technological and market demands.

Global CNC Machine Tool Maintenance Service Market Outlook:

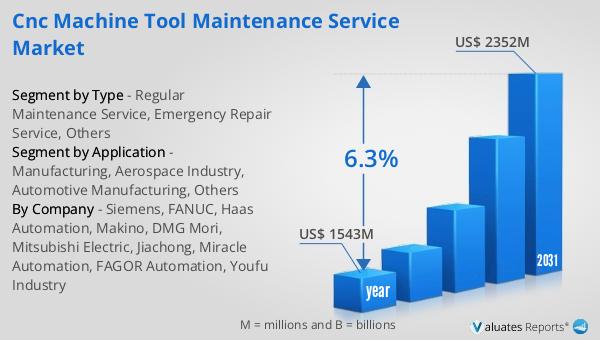

The global market for CNC Machine Tool Maintenance Service was valued at $1,543 million in 2024 and is anticipated to grow to a revised size of $2,352 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.3% over the forecast period. This growth is driven by the increasing demand for CNC machines across various industries, as they offer precision, efficiency, and flexibility in manufacturing processes. As companies continue to invest in advanced machinery to enhance their production capabilities, the need for reliable maintenance services becomes more critical. The market's expansion is also fueled by technological advancements, which have led to the development of more sophisticated CNC machines that require specialized maintenance and repair services. Additionally, the growing trend towards automation and smart manufacturing is expected to further boost the demand for CNC machine tool maintenance services, as companies seek to optimize their operations and reduce downtime. With the global manufacturing sector continuing to expand, the CNC Machine Tool Maintenance Service Market is poised for significant growth, offering numerous opportunities for service providers to cater to the evolving needs of their clients. By providing comprehensive maintenance solutions, these companies play a vital role in ensuring the smooth operation of CNC machines and supporting the overall efficiency and productivity of the industries they serve.

| Report Metric | Details |

| Report Name | CNC Machine Tool Maintenance Service Market |

| Accounted market size in year | US$ 1543 million |

| Forecasted market size in 2031 | US$ 2352 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Siemens, FANUC, Haas Automation, Makino, DMG Mori, Mitsubishi Electric, Jiachong, Miracle Automation, FAGOR Automation, Youfu Industry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |