What is Global Capsule Desiccant Market?

The Global Capsule Desiccant Market is a specialized segment within the broader desiccant industry, focusing on the production and distribution of small, capsule-shaped desiccants. These capsules are designed to absorb moisture and control humidity levels within various packaging environments, thereby protecting sensitive products from moisture-related damage. The market is driven by the increasing demand for moisture control solutions in industries such as pharmaceuticals, electronics, and food packaging. Capsule desiccants are particularly valued for their compact size, ease of use, and effectiveness in maintaining product integrity during storage and transportation. They are typically made from materials like silica gel, activated carbon, or clay, which have high moisture absorption capacities. The market is characterized by continuous innovation, with manufacturers striving to develop more efficient and environmentally friendly desiccant solutions. As global trade and e-commerce continue to expand, the need for reliable moisture control solutions is expected to grow, further propelling the Global Capsule Desiccant Market. This market is also influenced by regulatory standards and environmental considerations, as companies seek to comply with safety and sustainability requirements. Overall, the Global Capsule Desiccant Market plays a crucial role in ensuring product quality and longevity across various industries.

Active Desiccant, Inactive Desiccant in the Global Capsule Desiccant Market:

Active desiccants and inactive desiccants are two primary categories within the Global Capsule Desiccant Market, each serving distinct purposes based on their chemical properties and applications. Active desiccants are materials that actively absorb moisture from the surrounding environment. They are typically composed of substances like silica gel, molecular sieves, or calcium oxide, which have a high affinity for water molecules. Silica gel, for instance, is a popular choice due to its non-toxic nature and high moisture absorption capacity. It works by adsorbing water vapor onto its surface, effectively reducing humidity levels within a sealed environment. Molecular sieves, on the other hand, are crystalline aluminosilicates that can absorb moisture at a molecular level, making them ideal for applications requiring precise humidity control. Calcium oxide, also known as quicklime, reacts with water to form calcium hydroxide, a process that effectively removes moisture from the air. These active desiccants are widely used in industries where moisture control is critical, such as pharmaceuticals, electronics, and food packaging. Inactive desiccants, in contrast, do not chemically react with moisture but instead rely on physical processes to manage humidity levels. These materials, such as clay or activated carbon, have porous structures that allow them to trap moisture within their pores. Clay desiccants are often used in applications where cost-effectiveness is a priority, as they are relatively inexpensive and can absorb moderate amounts of moisture. Activated carbon, while primarily known for its adsorption of gases and odors, can also function as a desiccant by trapping moisture within its porous structure. Inactive desiccants are typically used in situations where the risk of chemical reactions with the product being protected is a concern, or where the desiccant needs to be regenerated and reused. The choice between active and inactive desiccants in the Global Capsule Desiccant Market depends on several factors, including the specific moisture control requirements, the nature of the product being protected, and cost considerations. Active desiccants are generally preferred in applications where precise humidity control is essential, such as in the packaging of pharmaceuticals or sensitive electronic components. Inactive desiccants, on the other hand, may be more suitable for less critical applications or where cost is a significant factor. Additionally, environmental considerations play a role in the selection process, as companies increasingly seek sustainable and eco-friendly desiccant solutions. Manufacturers in the Global Capsule Desiccant Market are continually innovating to develop new materials and technologies that enhance the performance and sustainability of both active and inactive desiccants. This ongoing innovation is crucial in meeting the evolving needs of industries that rely on effective moisture control solutions to protect their products and ensure quality and longevity.

Pharmaceuticals, Electronics, Optics, Other in the Global Capsule Desiccant Market:

The Global Capsule Desiccant Market finds extensive usage across various industries, including pharmaceuticals, electronics, optics, and others, each with unique requirements for moisture control. In the pharmaceutical industry, capsule desiccants are crucial for maintaining the stability and efficacy of medications. Many pharmaceutical products, such as tablets and capsules, are sensitive to moisture, which can lead to degradation, reduced potency, or even spoilage. Capsule desiccants help to maintain a dry environment within packaging, ensuring that medications remain effective throughout their shelf life. This is particularly important for products that are distributed globally, as they may be exposed to varying humidity levels during transportation and storage. In the electronics industry, moisture control is essential to prevent damage to sensitive components. Electronic devices and components, such as circuit boards and semiconductors, can be adversely affected by moisture, leading to corrosion, short circuits, or malfunction. Capsule desiccants are used to protect these components during manufacturing, storage, and transportation, ensuring that they remain in optimal condition until they reach the end user. The compact size and effectiveness of capsule desiccants make them an ideal choice for use in electronic packaging, where space is often limited. The optics industry also relies on capsule desiccants to protect sensitive optical components from moisture-related damage. Optical devices, such as cameras, lenses, and telescopes, require precise alignment and clarity to function correctly. Moisture can cause fogging, distortion, or even permanent damage to optical surfaces, compromising the performance of these devices. Capsule desiccants help to maintain a dry environment within optical packaging, preserving the quality and functionality of optical components. Beyond these industries, capsule desiccants are used in a variety of other applications where moisture control is critical. For example, in the food packaging industry, desiccants are used to extend the shelf life of products by preventing moisture-related spoilage. In the automotive industry, desiccants are used to protect sensitive components, such as airbags and sensors, from moisture damage. Additionally, capsule desiccants are used in the storage and transportation of valuable documents, artworks, and other items that require protection from humidity. Overall, the Global Capsule Desiccant Market plays a vital role in ensuring the quality and longevity of products across a wide range of industries. By providing effective moisture control solutions, capsule desiccants help to protect sensitive products from damage, reduce waste, and enhance customer satisfaction. As industries continue to evolve and expand, the demand for reliable and efficient desiccant solutions is expected to grow, further driving innovation and development within the Global Capsule Desiccant Market.

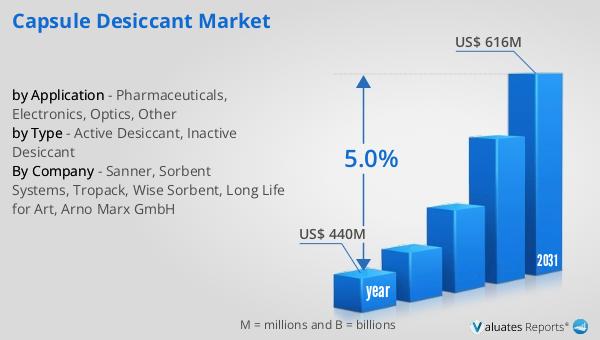

Global Capsule Desiccant Market Outlook:

In 2024, the global market for capsule desiccants was valued at approximately $440 million. This figure reflects the significant demand for moisture control solutions across various industries, driven by the need to protect sensitive products from moisture-related damage. Over the forecast period, the market is expected to experience steady growth, with projections indicating that it will reach a revised size of $616 million by 2031. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 5.0%, highlighting the increasing importance of effective desiccant solutions in maintaining product quality and longevity. The expansion of the market can be attributed to several factors, including the rising demand for pharmaceuticals, electronics, and other moisture-sensitive products, as well as advancements in desiccant technology that enhance performance and sustainability. As industries continue to globalize and supply chains become more complex, the need for reliable moisture control solutions is expected to grow, further driving the demand for capsule desiccants. Additionally, regulatory standards and environmental considerations are likely to influence market dynamics, as companies seek to comply with safety and sustainability requirements. Overall, the Global Capsule Desiccant Market is poised for continued growth, driven by the increasing need for effective moisture control solutions across a wide range of industries.

| Report Metric | Details |

| Report Name | Capsule Desiccant Market |

| Accounted market size in year | US$ 440 million |

| Forecasted market size in 2031 | US$ 616 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sanner, Sorbent Systems, Tropack, Wise Sorbent, Long Life for Art, Arno Marx GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |