What is Global Anti-Corrosion Lining Market?

The Global Anti-Corrosion Lining Market is a crucial segment within the industrial coatings industry, focusing on providing protective solutions to prevent corrosion in various environments. Corrosion is a natural process that deteriorates materials, especially metals, due to chemical reactions with their surroundings. This market encompasses a wide range of products designed to protect infrastructure, machinery, and equipment from the damaging effects of corrosion. These linings are essential in extending the lifespan of assets, reducing maintenance costs, and ensuring safety and efficiency in operations. The market is driven by the increasing demand for durable and long-lasting protective coatings in industries such as oil and gas, chemical processing, water treatment, and construction. With advancements in technology, the development of more effective and environmentally friendly anti-corrosion linings has become a priority. The market is characterized by a diverse range of materials and application methods, each tailored to specific industrial needs and environmental conditions. As industries continue to expand and infrastructure ages, the demand for reliable anti-corrosion solutions is expected to grow, making this market a vital component of industrial maintenance and asset protection strategies.

Rubber Lining, Plastic Lining, Glass Lining, Ceramic Lining in the Global Anti-Corrosion Lining Market:

Rubber lining is a popular choice in the Global Anti-Corrosion Lining Market due to its excellent resistance to abrasion and chemical attack. It is widely used in industries where equipment is exposed to harsh chemicals and abrasive materials, such as in mining, chemical processing, and water treatment facilities. Rubber linings are applied to the interior surfaces of tanks, pipes, and other equipment to protect them from corrosion and wear. The flexibility of rubber allows it to absorb impact and vibrations, reducing the risk of damage to the underlying structure. Additionally, rubber linings can be customized to fit complex shapes and sizes, making them versatile for various applications. Plastic lining, on the other hand, offers a lightweight and cost-effective solution for corrosion protection. It is commonly used in industries where weight is a concern, such as in the transportation and aerospace sectors. Plastic linings are resistant to a wide range of chemicals and can withstand high temperatures, making them suitable for use in harsh environments. They are often used in conjunction with other materials to enhance their protective properties. Glass lining is another option in the anti-corrosion market, known for its excellent chemical resistance and durability. It is often used in the pharmaceutical and food processing industries, where hygiene and purity are critical. Glass linings provide a smooth, non-porous surface that is easy to clean and maintain, reducing the risk of contamination. They are also resistant to thermal shock, making them suitable for use in processes involving rapid temperature changes. Ceramic lining is a high-performance option that offers exceptional resistance to abrasion and high temperatures. It is commonly used in industries such as power generation and cement manufacturing, where equipment is exposed to extreme conditions. Ceramic linings are applied to surfaces that experience high wear and tear, such as chutes, hoppers, and cyclones. They provide a hard, durable surface that can withstand the rigors of heavy-duty operations. Each of these lining materials has its unique advantages and is chosen based on the specific requirements of the application. The Global Anti-Corrosion Lining Market continues to evolve, with ongoing research and development efforts focused on improving the performance and sustainability of these protective solutions.

Chemical Industry, Oil Industry, Pharmaceutical Industry in the Global Anti-Corrosion Lining Market:

The Global Anti-Corrosion Lining Market plays a vital role in the chemical industry, where equipment and infrastructure are constantly exposed to corrosive substances. In chemical plants, anti-corrosion linings are used to protect tanks, pipes, and reactors from the aggressive chemicals used in various processes. These linings help prevent leaks and equipment failures, ensuring the safety and efficiency of operations. The use of anti-corrosion linings in the chemical industry also extends the lifespan of equipment, reducing the need for frequent replacements and maintenance. In the oil industry, anti-corrosion linings are essential for protecting pipelines, storage tanks, and offshore platforms from the harsh conditions of the marine environment. The oil industry is particularly susceptible to corrosion due to the presence of saltwater, crude oil, and other corrosive substances. Anti-corrosion linings help prevent leaks and spills, minimizing environmental impact and ensuring the safe transport and storage of oil and gas. In the pharmaceutical industry, anti-corrosion linings are used to maintain the integrity of equipment and facilities. The production of pharmaceuticals involves the use of various chemicals and solvents, which can be corrosive to equipment. Anti-corrosion linings help protect against chemical attack, ensuring the purity and quality of pharmaceutical products. They also provide a smooth, easy-to-clean surface that meets the stringent hygiene standards of the industry. Overall, the Global Anti-Corrosion Lining Market is crucial for maintaining the safety, efficiency, and longevity of equipment and infrastructure in these industries. By providing reliable protection against corrosion, these linings help reduce maintenance costs, prevent equipment failures, and ensure the smooth operation of industrial processes.

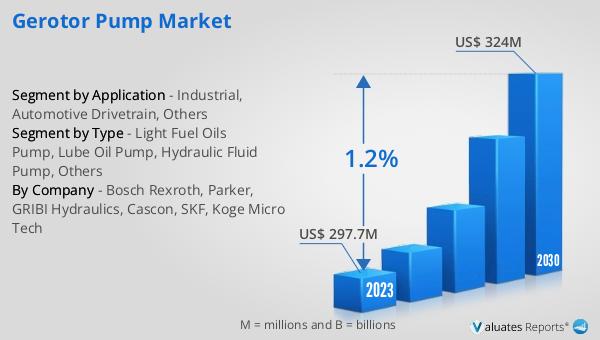

Global Anti-Corrosion Lining Market Outlook:

In 2024, the global market for Anti-Corrosion Lining was valued at approximately $14.28 billion. This market is anticipated to expand significantly, reaching an estimated value of $23.44 billion by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.4% over the forecast period. The increasing demand for anti-corrosion solutions across various industries is a key driver of this growth. As industries continue to expand and infrastructure ages, the need for effective and durable protective coatings becomes more critical. The market's growth is also supported by advancements in technology, leading to the development of more efficient and environmentally friendly anti-corrosion linings. These innovations are expected to enhance the performance and sustainability of protective solutions, further driving market expansion. The Global Anti-Corrosion Lining Market is poised for significant growth, driven by the increasing demand for reliable and long-lasting protective coatings in industries such as oil and gas, chemical processing, and construction. As the market continues to evolve, it will play a crucial role in industrial maintenance and asset protection strategies, ensuring the safety and efficiency of operations across various sectors.

| Report Metric | Details |

| Report Name | Anti-Corrosion Lining Market |

| Accounted market size in year | US$ 14280 million |

| Forecasted market size in 2031 | US$ 23440 million |

| CAGR | 7.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Arbonite, PPG Industries, Inc., The Sherwin-Williams Company, Ashland Inc., Axalta Coating Systems Ltd., Polycorp Ltd., Jotun A/S, Akzo Nobel NV., Steuler-KCH GmbH, Koch Knight LLC, BASF, SäKAPHEN GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |