What is Global Atmospheric Pipeline Coatings Market?

The Global Atmospheric Pipeline Coatings Market is a specialized sector within the broader coatings industry, focusing on the protection and longevity of pipelines exposed to atmospheric conditions. These coatings are essential for safeguarding pipelines from corrosion, weathering, and other environmental factors that can compromise their structural integrity. Pipelines are critical infrastructure components used for transporting oil, gas, water, and other substances over long distances. The coatings applied to these pipelines must withstand various environmental challenges, including UV radiation, moisture, temperature fluctuations, and chemical exposure. The market for these coatings is driven by the need to maintain pipeline efficiency, reduce maintenance costs, and extend the lifespan of pipeline systems. As infrastructure development continues globally, particularly in emerging economies, the demand for effective pipeline coatings is expected to grow. This market encompasses a range of coating types, each offering specific benefits and applications, tailored to meet the diverse needs of different pipeline projects. The coatings not only protect the pipelines but also ensure safety and reliability in the transportation of essential resources.

Epoxy Anticorrosive Coating, Fluorocarbon Coating, Polyurethane Coating, Others in the Global Atmospheric Pipeline Coatings Market:

Epoxy Anticorrosive Coating is a popular choice in the Global Atmospheric Pipeline Coatings Market due to its excellent adhesion properties and resistance to corrosion. This type of coating is primarily used to protect pipelines from rust and chemical degradation, which can occur due to exposure to harsh environmental conditions. Epoxy coatings form a hard, durable layer that adheres well to metal surfaces, providing a robust barrier against moisture and other corrosive elements. They are particularly effective in environments where pipelines are exposed to saltwater or industrial chemicals, making them ideal for use in coastal areas and industrial zones. Fluorocarbon Coating, on the other hand, is known for its exceptional resistance to UV radiation and weathering. This type of coating is often used in pipelines that are exposed to direct sunlight and extreme weather conditions. Fluorocarbon coatings provide a long-lasting finish that maintains its color and gloss over time, reducing the need for frequent maintenance and repainting. They are also resistant to chemical attacks, making them suitable for pipelines transporting aggressive substances. Polyurethane Coating is another important segment in the pipeline coatings market, offering flexibility and impact resistance. These coatings are used in applications where pipelines are subject to mechanical stress and abrasion. Polyurethane coatings provide a tough, elastic layer that can absorb impacts and resist wear and tear, ensuring the pipeline remains intact even under challenging conditions. They are also resistant to chemicals and UV radiation, making them versatile for various environments. Other types of coatings in the market include acrylic, zinc-rich, and bituminous coatings, each offering unique properties and benefits. Acrylic coatings are known for their fast-drying and weather-resistant properties, making them suitable for quick application in outdoor settings. Zinc-rich coatings provide excellent cathodic protection, preventing corrosion by acting as a sacrificial layer. Bituminous coatings offer waterproofing and protection against soil and water ingress, making them ideal for underground pipelines. Each of these coatings plays a crucial role in the overall protection strategy for pipelines, ensuring they remain functional and safe throughout their operational life.

Petroleum Gas, Industrial Field, Chemical Treatment, City Water Supply, Others in the Global Atmospheric Pipeline Coatings Market:

The Global Atmospheric Pipeline Coatings Market finds extensive usage across various sectors, including Petroleum Gas, Industrial Field, Chemical Treatment, City Water Supply, and others. In the Petroleum Gas sector, pipeline coatings are crucial for protecting the infrastructure that transports oil and gas from production sites to refineries and distribution centers. These coatings prevent corrosion and leaks, ensuring the safe and efficient flow of petroleum products. The harsh environments in which these pipelines operate, such as offshore platforms and desert regions, necessitate the use of robust coatings that can withstand extreme conditions. In the Industrial Field, pipeline coatings are used to protect pipelines that transport raw materials and finished products within manufacturing facilities. These coatings help maintain the integrity of the pipelines, preventing contamination and ensuring the smooth operation of industrial processes. In Chemical Treatment facilities, pipeline coatings are essential for protecting pipelines that carry corrosive chemicals and waste products. The coatings provide a barrier against chemical attacks, preventing leaks and ensuring the safe handling of hazardous materials. In City Water Supply systems, pipeline coatings are used to protect the infrastructure that delivers clean water to urban and rural areas. These coatings prevent corrosion and contamination, ensuring the safety and quality of the water supply. Other applications of pipeline coatings include their use in agricultural irrigation systems, mining operations, and power generation facilities. In each of these areas, the coatings play a vital role in maintaining the efficiency and reliability of the pipeline infrastructure, reducing maintenance costs, and extending the lifespan of the systems. The diverse applications of pipeline coatings highlight their importance in supporting critical infrastructure and ensuring the safe and efficient transportation of essential resources.

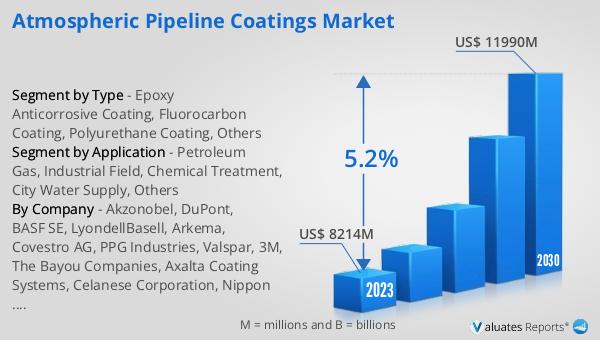

Global Atmospheric Pipeline Coatings Market Outlook:

The global market for Atmospheric Pipeline Coatings was valued at $9,259 million in 2024, and it is anticipated to grow to a revised size of $13,140 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.2% during the forecast period. This growth is driven by the increasing demand for pipeline infrastructure across various sectors, including oil and gas, water supply, and industrial applications. As economies continue to develop and urbanize, the need for efficient and reliable pipeline systems becomes more critical. The expansion of the market is also supported by advancements in coating technologies, which offer improved protection and performance. These innovations enable pipeline operators to reduce maintenance costs and extend the lifespan of their infrastructure, contributing to the overall growth of the market. Additionally, the growing awareness of environmental protection and the need to minimize the environmental impact of pipeline operations are driving the adoption of advanced coatings that offer enhanced resistance to corrosion and chemical exposure. As a result, the market for atmospheric pipeline coatings is expected to continue its upward trajectory, providing opportunities for manufacturers and suppliers to expand their offerings and meet the evolving needs of the industry.

| Report Metric | Details |

| Report Name | Atmospheric Pipeline Coatings Market |

| Accounted market size in year | US$ 9259 million |

| Forecasted market size in 2031 | US$ 13140 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Akzonobel, DuPont, BASF SE, LyondellBasell, Arkema, Covestro AG, PPG Industries, Valspar, 3M, The Bayou Companies, Axalta Coating Systems, Celanese Corporation, Nippon Paint, Sherwin-Williams, KCC Corporation, Jotun Powder Coatings |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |