What is Global Alumina Thin Film Ceramic Substrates in Electronic Packaging Market?

The Global Alumina Thin Film Ceramic Substrates in Electronic Packaging Market is a specialized segment within the broader electronic packaging industry. These substrates are crucial components used in various electronic devices due to their excellent thermal conductivity, electrical insulation, and mechanical strength. Alumina, or aluminum oxide, is a ceramic material that provides a stable and reliable platform for mounting electronic circuits and components. The thin film ceramic substrates are particularly valued for their ability to support high-density circuitry, which is essential for modern electronic devices that demand compactness and efficiency. These substrates are used in a wide range of applications, from consumer electronics to industrial equipment, due to their ability to withstand high temperatures and harsh environments. As technology advances and the demand for more efficient and compact electronic devices grows, the market for alumina thin film ceramic substrates is expected to expand, driven by innovations in electronic packaging and the increasing complexity of electronic devices.

Ultra-Thin Alumina Ceramic Substrate, Standard Thickness Alumina Ceramic Substrate, Thick Alumina Ceramic Substrate in the Global Alumina Thin Film Ceramic Substrates in Electronic Packaging Market:

Ultra-Thin Alumina Ceramic Substrates are a key component in the Global Alumina Thin Film Ceramic Substrates in Electronic Packaging Market. These substrates are characterized by their minimal thickness, which allows for the creation of lightweight and compact electronic devices. The ultra-thin nature of these substrates makes them ideal for applications where space and weight are critical factors, such as in portable electronics and advanced computing devices. Despite their thinness, these substrates maintain excellent thermal and electrical properties, ensuring reliable performance in demanding applications. Standard Thickness Alumina Ceramic Substrates, on the other hand, offer a balance between performance and cost. They are widely used in various electronic applications due to their robustness and ability to handle moderate thermal and electrical loads. These substrates are often employed in consumer electronics, automotive electronics, and industrial equipment, where reliability and durability are essential. Thick Alumina Ceramic Substrates are designed for applications that require enhanced mechanical strength and thermal management. These substrates are typically used in high-power electronic devices, such as power modules and RF amplifiers, where efficient heat dissipation is crucial. The thickness of these substrates allows them to support larger and more complex circuitry, making them suitable for demanding industrial and military applications. Each type of alumina ceramic substrate plays a vital role in the electronic packaging market, catering to different needs and requirements based on their unique properties and capabilities.

LED, Laser Diodes, RF and Optical Communication, Others in the Global Alumina Thin Film Ceramic Substrates in Electronic Packaging Market:

The usage of Global Alumina Thin Film Ceramic Substrates in Electronic Packaging Market spans several critical areas, including LED, Laser Diodes, RF and Optical Communication, and others. In the LED industry, these substrates are essential for managing heat dissipation, which is crucial for maintaining the performance and longevity of LED lights. The high thermal conductivity of alumina substrates ensures that heat generated by the LEDs is efficiently dissipated, preventing overheating and ensuring consistent light output. In the realm of Laser Diodes, alumina thin film ceramic substrates provide a stable and reliable platform for mounting these sensitive components. The substrates' excellent thermal and electrical properties help maintain the precision and efficiency of laser diodes, which are used in a variety of applications, from telecommunications to medical devices. In RF and Optical Communication, alumina substrates play a crucial role in ensuring signal integrity and performance. The substrates' ability to handle high frequencies and provide excellent electrical insulation makes them ideal for use in RF amplifiers, filters, and other communication devices. Additionally, the substrates' robustness and reliability make them suitable for use in harsh environments, such as in aerospace and defense applications. Beyond these specific areas, alumina thin film ceramic substrates are also used in a wide range of other electronic applications, including sensors, power electronics, and automotive electronics. Their versatility and performance make them a preferred choice for engineers and designers looking to create reliable and efficient electronic devices.

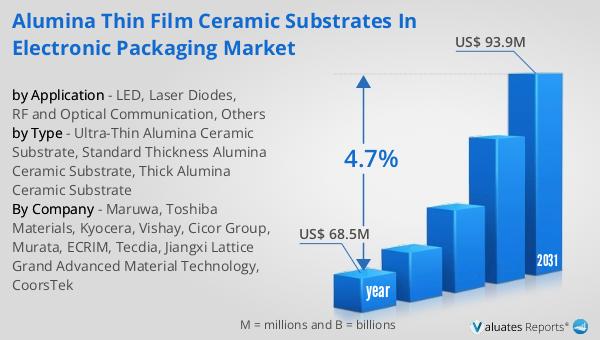

Global Alumina Thin Film Ceramic Substrates in Electronic Packaging Market Outlook:

The global market for Alumina Thin Film Ceramic Substrates in Electronic Packaging was valued at US$ 68.5 million in 2024 and is projected to reach a revised size of US$ 93.9 million by 2031, growing at a CAGR of 4.7% during the forecast period. This growth reflects the increasing demand for advanced electronic packaging solutions that can support the miniaturization and enhanced performance of electronic devices. As industries such as consumer electronics, automotive, and telecommunications continue to evolve, the need for reliable and efficient packaging solutions becomes more critical. Alumina thin film ceramic substrates offer a unique combination of thermal, electrical, and mechanical properties that make them ideal for a wide range of applications. The market's growth is also driven by technological advancements and innovations in electronic packaging, which are enabling the development of more complex and compact devices. As the market continues to expand, manufacturers and suppliers of alumina thin film ceramic substrates are likely to focus on enhancing their product offerings and capabilities to meet the evolving needs of their customers.

| Report Metric | Details |

| Report Name | Alumina Thin Film Ceramic Substrates in Electronic Packaging Market |

| Accounted market size in year | US$ 68.5 million |

| Forecasted market size in 2031 | US$ 93.9 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Maruwa, Toshiba Materials, Kyocera, Vishay, Cicor Group, Murata, ECRIM, Tecdia, Jiangxi Lattice Grand Advanced Material Technology, CoorsTek |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |