What is Global Aircraft Ducting Repair Market?

The Global Aircraft Ducting Repair Market is a specialized segment within the aviation industry that focuses on the maintenance and repair of ducting systems in aircraft. These ducting systems are crucial for various functions, including air conditioning, ventilation, and the distribution of air throughout the aircraft. As aircraft age, the ducting systems can experience wear and tear, leading to the need for repairs to ensure optimal performance and safety. The market encompasses a range of services, from minor repairs to complete overhauls, and involves the use of advanced materials and technologies to restore ducting systems to their original condition. The demand for aircraft ducting repair services is driven by the increasing number of aging aircraft in service, as well as the need for airlines to maintain high safety standards and operational efficiency. Additionally, regulatory requirements and the growing emphasis on sustainability and cost-effectiveness in the aviation industry further contribute to the market's growth. Companies operating in this market offer a variety of solutions, including on-site repairs, off-site refurbishments, and customized maintenance programs tailored to the specific needs of different aircraft models.

Repair, Retrofit, Upgrade in the Global Aircraft Ducting Repair Market:

Repair, retrofit, and upgrade are three critical components of the Global Aircraft Ducting Repair Market, each playing a vital role in maintaining the functionality and efficiency of aircraft ducting systems. Repair involves the process of fixing any damage or wear in the ducting systems to restore them to their original condition. This can include patching leaks, replacing damaged sections, and reinforcing weakened areas. The repair process often requires specialized tools and materials, as well as skilled technicians who are trained to work with the complex systems found in modern aircraft. Retrofit, on the other hand, involves updating older ducting systems with newer technologies or materials to improve performance and extend the lifespan of the aircraft. This can include replacing outdated components with more efficient ones, integrating advanced materials that offer better durability and resistance to environmental factors, and implementing new technologies that enhance the overall functionality of the ducting systems. Retrofit projects are often undertaken to comply with new regulatory standards or to improve the aircraft's operational efficiency and reduce maintenance costs. Upgrade refers to the process of enhancing the existing ducting systems to meet higher performance standards or to accommodate new features and capabilities. This can involve installing more advanced control systems, improving the insulation and noise reduction properties of the ducting, and incorporating smart technologies that allow for real-time monitoring and diagnostics. Upgrades are typically driven by the need to improve passenger comfort, reduce energy consumption, and enhance the overall safety and reliability of the aircraft. Together, repair, retrofit, and upgrade services form a comprehensive approach to maintaining and improving aircraft ducting systems, ensuring that they continue to meet the evolving needs of the aviation industry. Companies offering these services must stay abreast of the latest technological advancements and regulatory changes to provide effective solutions that meet the highest standards of quality and safety. The growing demand for these services is fueled by the increasing complexity of modern aircraft, the need for cost-effective maintenance solutions, and the desire to extend the operational life of existing aircraft fleets. As the aviation industry continues to evolve, the importance of repair, retrofit, and upgrade services in the Global Aircraft Ducting Repair Market is expected to grow, providing opportunities for companies to innovate and expand their offerings to meet the changing needs of their customers.

Commercial, Military in the Global Aircraft Ducting Repair Market:

The usage of the Global Aircraft Ducting Repair Market in commercial and military sectors highlights the diverse applications and importance of maintaining ducting systems in different types of aircraft. In the commercial aviation sector, aircraft ducting systems are essential for ensuring passenger comfort and safety. These systems are responsible for regulating cabin temperature, providing fresh air, and maintaining optimal air pressure levels throughout the flight. As commercial airlines operate a large number of flights daily, the wear and tear on ducting systems can be significant, necessitating regular maintenance and repair to prevent any disruptions in service. The Global Aircraft Ducting Repair Market provides commercial airlines with the necessary services to keep their aircraft in top condition, ensuring that passengers enjoy a comfortable and safe flying experience. In the military sector, aircraft ducting systems play a crucial role in the performance and reliability of military aircraft. These systems are responsible for maintaining the optimal operating conditions for both the crew and the aircraft's sensitive equipment. Military aircraft often operate in harsh environments and under demanding conditions, which can put additional stress on ducting systems. The Global Aircraft Ducting Repair Market offers specialized services tailored to the unique needs of military aircraft, ensuring that they remain operationally ready and capable of performing their missions effectively. The repair and maintenance of ducting systems in military aircraft are critical for maintaining the aircraft's performance, reliability, and safety, as well as for extending their operational lifespan. Both commercial and military sectors benefit from the advancements in materials and technologies offered by the Global Aircraft Ducting Repair Market. The use of lightweight, durable materials and advanced repair techniques helps to improve the efficiency and longevity of ducting systems, reducing the overall maintenance costs and downtime for aircraft operators. Additionally, the integration of smart technologies and real-time monitoring systems allows for proactive maintenance and early detection of potential issues, further enhancing the reliability and safety of aircraft operations. As the aviation industry continues to grow and evolve, the importance of maintaining and repairing aircraft ducting systems in both commercial and military sectors will remain a critical aspect of ensuring the safety, efficiency, and performance of aircraft worldwide.

Global Aircraft Ducting Repair Market Outlook:

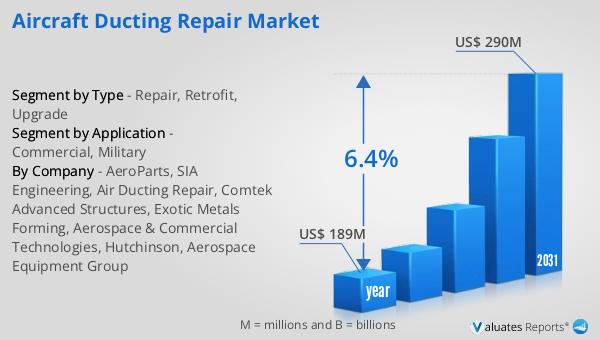

The global market for Aircraft Ducting Repair was valued at $189 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is expected to reach a revised size of $290 million, reflecting a compound annual growth rate (CAGR) of 6.4% during the forecast period. This growth can be attributed to several factors, including the increasing number of aging aircraft in service, the need for airlines and military operators to maintain high safety standards, and the growing emphasis on cost-effective maintenance solutions. As aircraft continue to age, the demand for ducting repair services is expected to rise, driven by the need to ensure optimal performance and safety. Additionally, advancements in materials and repair technologies are enabling more efficient and effective repair solutions, further contributing to the market's growth. Companies operating in the Global Aircraft Ducting Repair Market are continually innovating and expanding their offerings to meet the evolving needs of their customers, providing a wide range of services that cater to both commercial and military aircraft operators. The market's growth is also supported by the increasing focus on sustainability and environmental responsibility within the aviation industry, as airlines and military operators seek to reduce their carbon footprint and improve the overall efficiency of their operations. As a result, the Global Aircraft Ducting Repair Market is poised for continued growth and development, offering numerous opportunities for companies to expand their presence and capitalize on the increasing demand for ducting repair services.

| Report Metric | Details |

| Report Name | Aircraft Ducting Repair Market |

| Accounted market size in year | US$ 189 million |

| Forecasted market size in 2031 | US$ 290 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | AeroParts, SIA Engineering, Air Ducting Repair, Comtek Advanced Structures, Exotic Metals Forming, Aerospace & Commercial Technologies, Hutchinson, Aerospace Equipment Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |