What is Weight Batching System - Global Market?

Weight batching systems are essential tools in various industries, designed to accurately measure and mix materials based on weight. These systems are crucial for ensuring consistency, quality, and efficiency in production processes. The global market for weight batching systems is driven by the increasing demand for precision in manufacturing and processing industries. These systems are employed in sectors such as food and beverage, pharmaceuticals, chemicals, and construction materials, where precise measurements are critical. The technology behind weight batching systems involves the use of load cells, sensors, and control systems to weigh and mix ingredients accurately. This ensures that the final product meets the required specifications and standards. The market is characterized by a range of systems, from fully automated to manual, catering to different industry needs and scales of operation. As industries continue to prioritize quality and efficiency, the demand for advanced weight batching systems is expected to grow, driving innovation and development in this field. The global market for weight batching systems is poised for significant growth, reflecting the increasing emphasis on precision and quality in manufacturing processes worldwide.

Fully Automatic System, Semi-automatic System, Manual System in the Weight Batching System - Global Market:

Weight batching systems can be categorized into three main types: fully automatic, semi-automatic, and manual systems. Each type offers distinct advantages and is suited to different operational needs and scales. Fully automatic systems are the most advanced, integrating sophisticated technology to perform weighing and batching tasks with minimal human intervention. These systems are equipped with advanced sensors, programmable logic controllers (PLCs), and user-friendly interfaces, allowing for precise control and monitoring of the batching process. They are ideal for large-scale operations where speed, accuracy, and consistency are paramount. Fully automatic systems reduce human error, increase efficiency, and ensure high-quality output, making them a preferred choice in industries with high production demands. On the other hand, semi-automatic systems offer a balance between automation and manual control. These systems require some level of human intervention, typically for tasks such as loading materials or initiating the batching process. While they may not offer the same level of precision as fully automatic systems, they provide flexibility and are often more cost-effective for medium-sized operations. Semi-automatic systems are suitable for businesses that require a degree of customization in their processes or have variable production needs. Manual systems, as the name suggests, rely heavily on human operation. These systems are the most basic form of weight batching, where operators manually weigh and mix materials. While they lack the precision and efficiency of automated systems, manual systems are often used in small-scale operations or in situations where the cost of automation cannot be justified. They offer the advantage of simplicity and are easy to operate and maintain. However, they are more prone to human error and can be less efficient in terms of time and resource utilization. In the global market, the choice between these systems depends on various factors, including the scale of operation, budget, and specific industry requirements. Fully automatic systems are gaining popularity in industries where precision and efficiency are critical, while semi-automatic and manual systems continue to serve niche markets where flexibility and cost considerations are more important. As technology advances, the integration of IoT and AI in weight batching systems is expected to further enhance their capabilities, offering even greater precision and efficiency across all types of systems.

Food and Beverage Industry, Pharmaceutical Manufacturing, Chemical Production, Construction Materials, Others in the Weight Batching System - Global Market:

Weight batching systems play a crucial role in various industries, ensuring precise measurement and mixing of materials to maintain quality and consistency. In the food and beverage industry, these systems are vital for producing products with consistent taste, texture, and nutritional content. They help in accurately measuring ingredients, reducing waste, and ensuring compliance with food safety standards. In pharmaceutical manufacturing, weight batching systems are essential for ensuring the correct dosage of active ingredients in medications. Precision is critical in this industry to ensure the efficacy and safety of pharmaceutical products. These systems help in maintaining strict quality control and regulatory compliance, which are paramount in pharmaceutical production. In chemical production, weight batching systems are used to mix chemicals in precise proportions, ensuring the desired chemical reactions and product quality. They help in minimizing errors and improving safety by reducing the risk of incorrect chemical mixing. In the construction materials industry, weight batching systems are used to mix materials such as cement, sand, and aggregates in precise proportions to produce high-quality concrete and other construction materials. These systems ensure consistency in the quality of construction materials, which is crucial for the structural integrity of buildings and infrastructure. Other industries, such as cosmetics and textiles, also benefit from weight batching systems, where precise measurement and mixing of ingredients are essential for product quality and consistency. Overall, weight batching systems are indispensable tools in various industries, contributing to improved efficiency, quality, and safety in production processes.

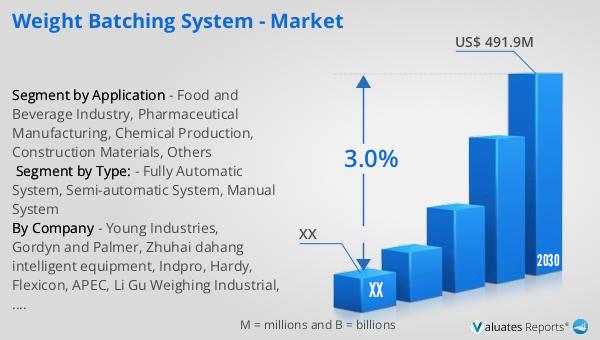

Weight Batching System - Global Market Outlook:

The global market for weight batching systems was valued at approximately $400 million in 2023. It is projected to grow to a revised size of around $491.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.0% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for precision and efficiency in manufacturing and processing industries worldwide. As industries continue to prioritize quality and consistency in their production processes, the adoption of advanced weight batching systems is expected to rise. The market's expansion is driven by technological advancements, increasing automation, and the need for compliance with stringent quality standards across various sectors. The growing emphasis on reducing waste and improving resource utilization also contributes to the market's growth. As a result, manufacturers are investing in innovative weight batching solutions to enhance their production capabilities and meet the evolving demands of their customers. The global weight batching system market is poised for steady growth, reflecting the ongoing trends towards automation and precision in industrial processes.

| Report Metric | Details |

| Report Name | Weight Batching System - Market |

| Forecasted market size in 2030 | US$ 491.9 million |

| CAGR | 3.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Young Industries, Gordyn and Palmer, Zhuhai dahang intelligent equipment, Indpro, Hardy, Flexicon, APEC, Li Gu Weighing Industrial, pneuCONVEYOR, NEWTON, Modern Sheller Industries, RIECO, Sprint Consys Private, P-SQUARE TECHNOLOGIES, MACTEX, rajdeepengg |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |