What is Oxygen Sensor Recovery - Global Market?

Oxygen Sensor Recovery is a niche yet crucial segment within the global market, focusing on the restoration and reuse of oxygen sensors. These sensors are vital components in various industries, particularly in automotive and electronics, where they play a key role in monitoring and controlling oxygen levels. The recovery process involves refurbishing used or faulty sensors to extend their lifespan, thereby reducing waste and promoting sustainability. This market is driven by the increasing demand for cost-effective and environmentally friendly solutions. As industries strive to minimize their carbon footprint and adhere to stringent environmental regulations, the recovery of oxygen sensors becomes an attractive option. The global market for Oxygen Sensor Recovery was valued at approximately US$ 110 million in 2023, with projections indicating a growth to US$ 135.3 million by 2030. This growth is supported by advancements in recovery technologies and the rising awareness of sustainable practices. The market's expansion is further fueled by the development of more efficient recovery methods, which are both cost-effective and environmentally friendly, aligning with the global trend towards sustainability. As industries continue to prioritize eco-friendly solutions, the demand for oxygen sensor recovery is expected to rise, making it a significant area of interest for stakeholders.

Thermal Processing, Chemical Processing, Plasma Processing, Others in the Oxygen Sensor Recovery - Global Market:

The Oxygen Sensor Recovery market encompasses various processing methods, each contributing uniquely to the restoration of sensors. Thermal processing is a widely used technique that involves heating the sensors to high temperatures to remove contaminants and restore functionality. This method is particularly effective for sensors that have been exposed to harsh environments, as it can eliminate residues that impair performance. Chemical processing, on the other hand, utilizes chemical solutions to clean and refurbish sensors. This approach is beneficial for sensors with delicate components that may be damaged by high temperatures. Chemical processing can effectively dissolve and remove impurities, ensuring the sensor's sensitivity and accuracy are maintained. Plasma processing is another innovative method employed in the recovery of oxygen sensors. It involves the use of ionized gases to clean and rejuvenate the sensor's surface. This technique is advantageous for its precision and ability to reach areas that are difficult to clean using traditional methods. Plasma processing is particularly useful for sensors with complex geometries or those used in high-tech applications. Additionally, other methods such as ultrasonic cleaning and laser ablation are also utilized in the recovery process. Ultrasonic cleaning uses high-frequency sound waves to agitate a fluid, effectively removing dirt and contaminants from the sensor's surface. Laser ablation, on the other hand, employs laser beams to remove layers of material, providing a precise and controlled cleaning process. Each of these methods offers distinct advantages, and the choice of technique depends on the specific requirements of the sensor and the industry it serves. The diversity of processing methods in the Oxygen Sensor Recovery market highlights the industry's commitment to innovation and sustainability. By employing a range of techniques, the market can cater to the varied needs of different sectors, ensuring that sensors are restored to optimal performance levels. As the demand for efficient and eco-friendly recovery solutions continues to grow, these processing methods will play a crucial role in shaping the future of the Oxygen Sensor Recovery market.

Automotive Industry, Electronics Industry, Jewelry Industry, Aerospace Industry, Others in the Oxygen Sensor Recovery - Global Market:

The application of Oxygen Sensor Recovery spans across several industries, each benefiting from the restoration and reuse of these critical components. In the automotive industry, oxygen sensors are essential for monitoring exhaust gases and ensuring optimal engine performance. The recovery of these sensors not only reduces costs for manufacturers but also supports environmental sustainability by minimizing waste. As vehicles become more advanced, the demand for reliable and efficient oxygen sensors increases, making recovery an attractive option for automotive companies. In the electronics industry, oxygen sensors are used in various devices to monitor and control oxygen levels. The recovery of these sensors helps manufacturers maintain product quality while reducing production costs. By refurbishing used sensors, electronics companies can extend the lifespan of their products and contribute to a circular economy. The jewelry industry also benefits from oxygen sensor recovery, particularly in processes that involve the use of oxygen for metalworking and refining. Recovered sensors ensure precise oxygen levels, which are crucial for achieving high-quality finishes and maintaining the integrity of precious metals. In the aerospace industry, oxygen sensors play a vital role in monitoring cabin air quality and engine performance. The recovery of these sensors is critical for ensuring the safety and efficiency of aircraft operations. By refurbishing sensors, aerospace companies can reduce maintenance costs and enhance the reliability of their systems. Additionally, other industries such as healthcare and environmental monitoring also utilize oxygen sensors for various applications. The recovery of these sensors supports the sustainability goals of these sectors by reducing waste and promoting the reuse of valuable resources. Overall, the usage of Oxygen Sensor Recovery in these industries highlights the importance of sustainable practices and the growing demand for cost-effective solutions. As industries continue to prioritize environmental responsibility, the recovery of oxygen sensors will remain a key focus area, driving innovation and growth in the global market.

Oxygen Sensor Recovery - Global Market Outlook:

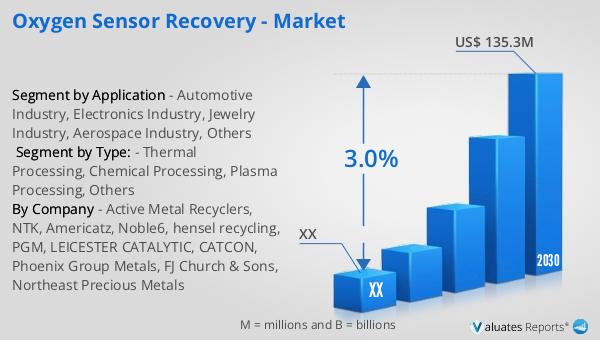

The global market for Oxygen Sensor Recovery was valued at approximately US$ 110 million in 2023, with expectations to reach a revised size of US$ 135.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.0% during the forecast period from 2024 to 2030. A notable trend within this market is the advancement of more efficient and cost-effective recovery methods. These innovations are driven by the increasing need for sustainable practices across various industries. As companies strive to reduce their environmental impact and adhere to stricter regulations, the demand for oxygen sensor recovery is anticipated to grow. The development of new technologies and processes that enhance the efficiency of sensor recovery is crucial in meeting this demand. By focusing on cost-effectiveness and environmental sustainability, the market is poised to attract more stakeholders and expand its reach. The emphasis on innovation and efficiency not only supports the growth of the Oxygen Sensor Recovery market but also aligns with the broader global trend towards sustainability. As industries continue to evolve and prioritize eco-friendly solutions, the recovery of oxygen sensors will play a pivotal role in shaping the future of various sectors. This focus on sustainable practices and technological advancements underscores the market's potential for growth and its significance in the global landscape.

| Report Metric | Details |

| Report Name | Oxygen Sensor Recovery - Market |

| Forecasted market size in 2030 | US$ 135.3 million |

| CAGR | 3.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Active Metal Recyclers, NTK, Americatz, Noble6, hensel recycling, PGM, LEICESTER CATALYTIC, CATCON, Phoenix Group Metals, FJ Church & Sons, Northeast Precious Metals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |