What is Wafer Edge Grinder - Global Market?

Wafer edge grinders are specialized machines used in the semiconductor industry to smooth and shape the edges of silicon wafers. These wafers are crucial components in the manufacturing of integrated circuits and other semiconductor devices. The process of edge grinding is essential because it helps prevent chipping and cracking, which can occur during subsequent manufacturing steps. By ensuring the edges are smooth and uniform, wafer edge grinders contribute to the overall quality and yield of semiconductor production. The global market for wafer edge grinders is driven by the increasing demand for semiconductors across various industries, including electronics, automotive, and telecommunications. As technology advances, the need for smaller and more efficient semiconductor devices grows, further fueling the demand for precise and reliable wafer edge grinding solutions. Manufacturers in this market are continually innovating to improve the performance and efficiency of their machines, catering to the evolving needs of the semiconductor industry. The market is characterized by a mix of established players and new entrants, each striving to offer advanced solutions that meet the stringent requirements of modern semiconductor manufacturing.

Single Axis, Dual Axis in the Wafer Edge Grinder - Global Market:

In the realm of wafer edge grinders, the distinction between single-axis and dual-axis machines is significant, as each type offers unique advantages and is suited to different applications within the semiconductor industry. Single-axis wafer edge grinders are designed to perform grinding operations along a single plane or axis. These machines are typically simpler in design and operation, making them a cost-effective choice for manufacturers who require basic edge grinding capabilities. Single-axis grinders are often used in applications where the primary goal is to achieve a uniform edge finish without the need for complex geometries or multi-directional grinding. They are particularly well-suited for smaller production runs or for use in research and development settings where flexibility and ease of use are paramount. On the other hand, dual-axis wafer edge grinders offer a more sophisticated approach to edge grinding by allowing for operations along two axes. This capability enables the machine to perform more complex grinding tasks, such as creating beveled edges or intricate edge profiles that are not possible with single-axis machines. Dual-axis grinders are ideal for high-volume production environments where precision and consistency are critical. These machines are often equipped with advanced features such as automated controls, real-time monitoring, and feedback systems that ensure optimal performance and minimal downtime. The choice between single-axis and dual-axis wafer edge grinders ultimately depends on the specific needs of the manufacturer, including factors such as production volume, desired edge profile, and budget constraints. As the semiconductor industry continues to evolve, the demand for both types of machines is expected to grow, driven by the need for increasingly sophisticated and efficient manufacturing processes. Manufacturers of wafer edge grinders are continually innovating to enhance the capabilities of their machines, offering solutions that cater to the diverse requirements of the global semiconductor market. Whether through the development of new grinding technologies or the integration of advanced automation and control systems, these innovations are helping to drive the industry forward, ensuring that wafer edge grinders remain a vital component of the semiconductor manufacturing process.

Below 4 Inch, 6-8 Inch, Above 8 Inch in the Wafer Edge Grinder - Global Market:

The usage of wafer edge grinders in the global market varies significantly based on the size of the wafers being processed. For wafers below 4 inches, wafer edge grinders are primarily used in niche applications, such as in the production of specialized semiconductor devices or in research and development settings. These smaller wafers are often used in applications where space constraints or specific performance characteristics are critical, such as in certain types of sensors or microelectromechanical systems (MEMS). The demand for wafer edge grinders in this segment is relatively limited compared to larger wafer sizes, but it remains an important niche market for manufacturers who specialize in these types of devices. For wafers in the 6-8 inch range, wafer edge grinders play a crucial role in the production of a wide variety of semiconductor devices, including microprocessors, memory chips, and power semiconductors. This segment represents a significant portion of the global wafer edge grinder market, as these wafer sizes are commonly used in many mainstream semiconductor applications. The demand for wafer edge grinders in this segment is driven by the need for high-quality, reliable semiconductor devices that can meet the performance and efficiency requirements of modern electronic products. As technology continues to advance, the need for precise and consistent edge grinding becomes increasingly important, making wafer edge grinders an essential tool in the manufacturing process. For wafers above 8 inches, wafer edge grinders are used in the production of advanced semiconductor devices, such as those used in high-performance computing, telecommunications, and automotive applications. These larger wafers allow for the production of more semiconductor devices per wafer, making them an attractive option for manufacturers looking to maximize efficiency and reduce costs. The demand for wafer edge grinders in this segment is driven by the need for high-volume production capabilities and the ability to produce devices with complex geometries and tight tolerances. As the semiconductor industry continues to push the boundaries of what is possible, the role of wafer edge grinders in the production of large-diameter wafers is expected to grow, further solidifying their importance in the global market.

Wafer Edge Grinder - Global Market Outlook:

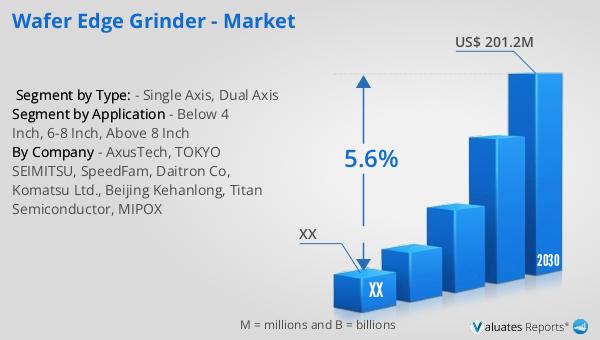

The global market for wafer edge grinders was valued at approximately $138.2 million in 2023. This market is projected to grow, reaching an estimated size of $201.2 million by 2030, with a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for semiconductor devices across various industries, which in turn drives the need for efficient and precise wafer edge grinding solutions. The market is characterized by a diverse range of players, each offering unique solutions to meet the evolving needs of the semiconductor industry. North America, Europe, and Japan collectively hold a significant share of the market, accounting for 23% of the global market share. This regional distribution highlights the importance of these areas as key hubs for semiconductor manufacturing and innovation. The growth in these regions is supported by strong industrial bases, advanced technological capabilities, and a focus on research and development. As the market continues to expand, manufacturers of wafer edge grinders are expected to invest in new technologies and innovations to maintain their competitive edge and meet the increasing demands of the global semiconductor industry.

| Report Metric | Details |

| Report Name | Wafer Edge Grinder - Market |

| Forecasted market size in 2030 | US$ 201.2 million |

| CAGR | 5.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AxusTech, TOKYO SEIMITSU, SpeedFam, Daitron Co, Komatsu Ltd., Beijing Kehanlong, Titan Semiconductor, MIPOX |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |