What is Aluminum Nitride (AlN) Wafer - Global Market?

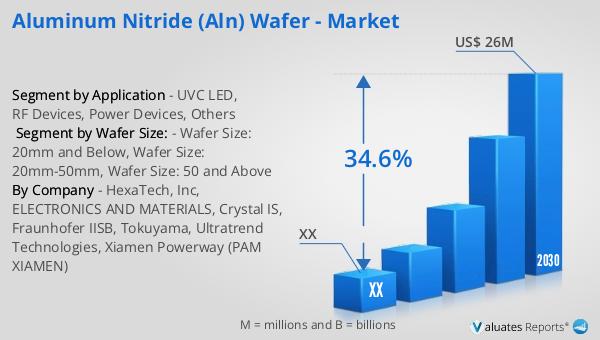

Aluminum Nitride (AlN) wafers are a critical component in the global market, primarily due to their unique properties and applications in various high-tech industries. AlN is a semiconductor material known for its excellent thermal conductivity, electrical insulation, and resistance to high temperatures, making it ideal for use in electronic devices. These wafers are used in the production of high-performance electronic components, such as LEDs, RF devices, and power electronics. The global market for AlN wafers is driven by the increasing demand for advanced electronic devices and the need for efficient thermal management solutions in electronics. As technology continues to advance, the demand for AlN wafers is expected to grow, driven by their applications in emerging technologies such as 5G communications, electric vehicles, and renewable energy systems. The market is characterized by a high level of competition, with several key players investing in research and development to improve the quality and performance of AlN wafers. The global market for Aluminum Nitride AlN Wafer was estimated to be worth US$ 3 million in 2023 and is forecast to a readjusted size of US$ 26 million by 2030 with a CAGR of 34.6% during the forecast period 2024-2030.

in the Aluminum Nitride (AlN) Wafer - Global Market:

Aluminum Nitride (AlN) wafers come in various types, each catering to different customer needs and applications in the global market. One of the primary types is the single-crystal AlN wafer, which is highly sought after for its superior thermal and electrical properties. These wafers are used in high-frequency and high-power electronic devices, where performance and reliability are critical. Single-crystal AlN wafers are particularly popular in the production of RF devices and power electronics, where they help improve efficiency and reduce heat generation. Another type is the polycrystalline AlN wafer, which is more cost-effective and is used in applications where the highest performance is not necessary. These wafers are often used in LED manufacturing, where they provide a good balance between performance and cost. Polycrystalline AlN wafers are also used in some power device applications, where they offer adequate thermal management at a lower price point. Additionally, there are doped AlN wafers, which have been modified with specific impurities to enhance certain properties. These wafers are used in specialized applications where tailored electrical or thermal characteristics are required. For example, doped AlN wafers can be used in sensors and other electronic components that require specific conductivity or thermal properties. The choice of AlN wafer type depends on the specific requirements of the application, including factors such as thermal conductivity, electrical insulation, and cost. Customers in the global market select the appropriate type of AlN wafer based on their specific needs and the performance requirements of their products. As the demand for advanced electronic devices continues to grow, the market for AlN wafers is expected to expand, with new types and variations being developed to meet the evolving needs of customers. The versatility and adaptability of AlN wafers make them a valuable component in the global market, with applications spanning a wide range of industries and technologies.

UVC LED, RF Devices, Power Devices, Others in the Aluminum Nitride (AlN) Wafer - Global Market:

Aluminum Nitride (AlN) wafers are used in various applications across different industries, with significant usage in UVC LEDs, RF devices, power devices, and other areas. In the UVC LED market, AlN wafers are valued for their excellent thermal conductivity and electrical insulation properties. UVC LEDs are used in sterilization and disinfection applications, where efficient heat dissipation is crucial to maintaining performance and longevity. AlN wafers help improve the thermal management of UVC LEDs, allowing them to operate at higher power levels and with greater efficiency. In the RF device market, AlN wafers are used to enhance the performance of high-frequency electronic components. RF devices, such as amplifiers and filters, require materials that can handle high power levels and frequencies without significant losses. AlN wafers provide the necessary thermal and electrical properties to support the efficient operation of RF devices, making them a popular choice in this market. In the power device market, AlN wafers are used to improve the thermal management and efficiency of power electronics. Power devices, such as transistors and diodes, generate significant amounts of heat during operation, which can affect their performance and reliability. AlN wafers help dissipate this heat, allowing power devices to operate at higher power levels and with greater efficiency. This makes AlN wafers an essential component in the development of advanced power electronics for applications such as electric vehicles and renewable energy systems. In addition to these specific markets, AlN wafers are also used in other applications where their unique properties are beneficial. For example, they are used in sensors and other electronic components that require high thermal conductivity and electrical insulation. The versatility of AlN wafers makes them a valuable component in a wide range of industries and applications, driving their demand in the global market. As technology continues to advance, the usage of AlN wafers is expected to grow, with new applications and markets emerging to take advantage of their unique properties.

Aluminum Nitride (AlN) Wafer - Global Market Outlook:

The global market for Aluminum Nitride (AlN) wafers was valued at approximately US$ 3 million in 2023. This market is projected to experience significant growth, reaching an estimated size of US$ 26 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 34.6% during the forecast period from 2024 to 2030. The North American market for AlN wafers also shows promising potential, although specific figures for 2023 and 2030 are not provided. However, it is anticipated that the North American market will follow a similar growth trajectory, driven by increasing demand for advanced electronic devices and the need for efficient thermal management solutions. The rapid growth of the AlN wafer market can be attributed to the expanding applications of AlN wafers in various high-tech industries, including telecommunications, automotive, and renewable energy. As these industries continue to evolve and adopt new technologies, the demand for AlN wafers is expected to rise, further fueling market growth. The competitive landscape of the AlN wafer market is characterized by the presence of several key players, each striving to enhance their product offerings and expand their market share. This competitive environment is likely to drive innovation and improvements in AlN wafer technology, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Aluminum Nitride (AlN) Wafer - Market |

| Forecasted market size in 2030 | US$ 26 million |

| CAGR | 34.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Wafer Size: |

|

| Segment by Application |

|

| By Region |

|

| By Company | HexaTech, Inc, ELECTRONICS AND MATERIALS, Crystal IS, Fraunhofer IISB, Tokuyama, Ultratrend Technologies, Xiamen Powerway (PAM XIAMEN) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |