What is Sterility Production Isolator - Global Market?

Sterility production isolators are specialized equipment used in various industries to maintain a sterile environment for the production and handling of sensitive products. These isolators are crucial in sectors like pharmaceuticals, biotechnology, and healthcare, where contamination can lead to significant product loss or health risks. The global market for sterility production isolators is driven by the increasing demand for sterile manufacturing processes, stringent regulatory requirements, and the growing focus on product quality and safety. These isolators provide a controlled environment by using physical barriers and air filtration systems to prevent contamination from external sources. They are designed to handle various processes, including aseptic filling, sterility testing, and compounding, ensuring that the products remain uncontaminated throughout the production cycle. The market is witnessing advancements in isolator technology, such as automation and integration with other manufacturing systems, which enhance efficiency and reduce human intervention. As industries continue to prioritize sterility and contamination control, the demand for sterility production isolators is expected to grow, making them an essential component of modern manufacturing processes.

Class II, Class III, Others in the Sterility Production Isolator - Global Market:

Sterility production isolators are categorized into different classes based on their design, functionality, and application. Class II isolators are widely used in laboratories and pharmaceutical industries for handling hazardous materials and protecting both the product and the operator. These isolators provide a controlled environment with a high level of protection against contamination, making them suitable for processes that require a sterile environment. Class II isolators are equipped with HEPA filters and airflow systems that ensure a continuous supply of clean air, preventing the entry of contaminants. They are designed to handle a wide range of applications, including sterility testing, aseptic processing, and compounding of sterile products. Class III isolators, on the other hand, offer a higher level of protection and are used in applications where the risk of contamination is extremely high. These isolators are completely sealed and provide a physical barrier between the operator and the product, ensuring maximum sterility. They are commonly used in the production of high-risk products, such as cytotoxic drugs and biological agents, where even the slightest contamination can have severe consequences. Class III isolators are equipped with advanced filtration systems and are designed to operate under negative pressure, preventing the escape of hazardous materials. In addition to Class II and Class III isolators, there are other types of isolators used in the sterility production isolator market. These include flexible film isolators, which are lightweight and portable, making them suitable for temporary or mobile applications. Flexible film isolators are often used in research and development settings, where flexibility and ease of use are important. They provide a sterile environment for small-scale production and testing, allowing researchers to conduct experiments without the risk of contamination. Another type of isolator is the rigid wall isolator, which is constructed from durable materials and provides a permanent solution for sterility production. Rigid wall isolators are commonly used in large-scale manufacturing facilities, where a robust and reliable solution is required. They offer a high level of protection against contamination and are designed to withstand harsh operating conditions. The choice of isolator depends on various factors, including the type of product being handled, the level of sterility required, and the specific application. Each class of isolator has its own advantages and limitations, and selecting the right isolator is crucial for ensuring product quality and safety. As the demand for sterile manufacturing processes continues to grow, the market for sterility production isolators is expected to expand, with advancements in technology and design driving innovation in this field.

Hospitals And Diagnostics Labs, Pharmaceutical And Biotechnological Industries, Others in the Sterility Production Isolator - Global Market:

Sterility production isolators play a vital role in various sectors, including hospitals and diagnostic labs, pharmaceutical and biotechnological industries, and other fields where maintaining a sterile environment is crucial. In hospitals and diagnostic labs, these isolators are used to ensure that medical procedures and tests are conducted in a contamination-free environment. They are essential for processes such as sterility testing, aseptic compounding, and the preparation of sterile pharmaceuticals. By providing a controlled environment, sterility production isolators help prevent infections and ensure the safety of both patients and healthcare professionals. In the pharmaceutical and biotechnological industries, sterility production isolators are used in the manufacturing of sterile drugs and biologics. These industries require a high level of sterility to ensure the safety and efficacy of their products. Isolators provide a controlled environment for processes such as aseptic filling, lyophilization, and sterility testing, ensuring that the products remain uncontaminated throughout the production cycle. They are also used in the production of vaccines, where maintaining a sterile environment is critical to prevent contamination and ensure the safety of the final product. In addition to hospitals, diagnostic labs, and pharmaceutical and biotechnological industries, sterility production isolators are also used in other fields where maintaining a sterile environment is essential. This includes industries such as food and beverage, cosmetics, and electronics, where contamination can lead to product spoilage or failure. In the food and beverage industry, isolators are used to ensure that products are manufactured and packaged in a contamination-free environment, preventing spoilage and ensuring product safety. In the cosmetics industry, isolators are used to prevent contamination during the production of sterile cosmetics, ensuring that the products are safe for use. In the electronics industry, isolators are used to prevent contamination during the production of sensitive electronic components, ensuring their reliability and performance. Overall, sterility production isolators are essential for maintaining a sterile environment in various industries, ensuring product quality and safety. As the demand for sterile manufacturing processes continues to grow, the use of sterility production isolators is expected to increase, driving innovation and advancements in this field.

Sterility Production Isolator - Global Market Outlook:

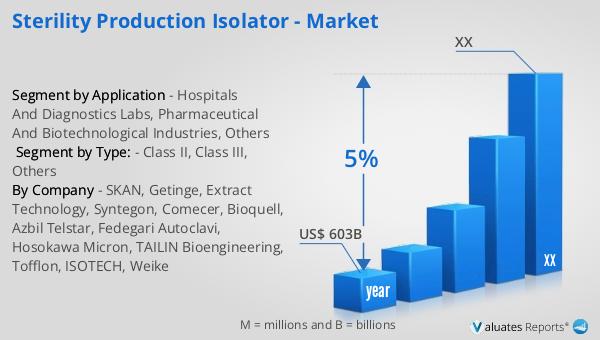

According to our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including the increasing demand for advanced medical technologies, the rising prevalence of chronic diseases, and the growing aging population. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the demand for innovative medical devices is expected to rise. This includes devices used in diagnostics, treatment, and monitoring, as well as those used in surgical procedures and patient care. The market is also being driven by advancements in technology, such as the development of minimally invasive devices, wearable health monitors, and telemedicine solutions. These innovations are transforming the way healthcare is delivered, making it more accessible and efficient. Additionally, the increasing focus on personalized medicine and the integration of artificial intelligence and data analytics in healthcare are expected to further drive the growth of the medical device market. As the market continues to expand, companies are investing in research and development to bring new and innovative products to market, meeting the evolving needs of healthcare providers and patients.

| Report Metric | Details |

| Report Name | Sterility Production Isolator - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SKAN, Getinge, Extract Technology, Syntegon, Comecer, Bioquell, Azbil Telstar, Fedegari Autoclavi, Hosokawa Micron, TAILIN Bioengineering, Tofflon, ISOTECH, Weike |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |