What is Slider Bed Belt Conveyor - Global Market?

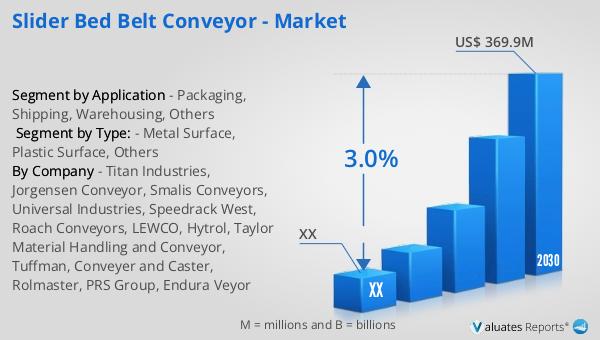

The Slider Bed Belt Conveyor is a crucial component in the global market, serving as an efficient and versatile solution for material handling across various industries. This type of conveyor system is designed with a flat surface, or "bed," over which a continuous belt slides, making it ideal for transporting goods of different sizes and weights. The global market for Slider Bed Belt Conveyors was valued at approximately US$ 300.8 million in 2023 and is projected to grow to US$ 369.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.0% from 2024 to 2030. This growth is driven by the increasing automation of manufacturing and distribution processes, where these conveyors are integrated with advanced technologies like robotic arms and sensors to enhance operational efficiency and reduce labor costs. The adaptability of slider bed belt conveyors to various industrial needs, along with their ability to seamlessly integrate with other equipment, makes them a preferred choice in the market. As industries continue to evolve and demand more efficient material handling solutions, the slider bed belt conveyor market is expected to expand, offering innovative solutions to meet the changing needs of businesses worldwide.

Metal Surface, Plastic Surface, Others in the Slider Bed Belt Conveyor - Global Market:

In the context of the Slider Bed Belt Conveyor global market, the materials used for the conveyor surfaces play a significant role in determining their application and efficiency. Metal surfaces are commonly used in environments where durability and strength are paramount. These conveyors are ideal for transporting heavy or abrasive materials, as the metal surface can withstand significant wear and tear. Metal surfaces also offer excellent resistance to high temperatures and corrosive substances, making them suitable for industries such as mining, metallurgy, and heavy manufacturing. The robustness of metal surfaces ensures a long lifespan and reliable performance, even under challenging conditions. On the other hand, plastic surfaces are favored for their lightweight and flexible properties. They are often used in industries where the conveyed materials are lighter and require a gentler handling process, such as in food processing, pharmaceuticals, and electronics. Plastic surfaces are also resistant to moisture and chemicals, making them easy to clean and maintain, which is crucial in industries with stringent hygiene standards. Additionally, plastic surfaces can be customized in terms of color and texture, allowing for better product differentiation and aesthetic appeal. Beyond metal and plastic, other materials are also utilized in slider bed belt conveyors to cater to specific industry needs. For instance, rubber surfaces provide excellent grip and shock absorption, making them suitable for transporting fragile or irregularly shaped items. Fabric surfaces, often reinforced with synthetic fibers, offer a balance between flexibility and strength, making them ideal for applications where both durability and adaptability are required. The choice of surface material in slider bed belt conveyors is influenced by factors such as the nature of the materials being transported, the environmental conditions, and the specific requirements of the industry. As the global market for slider bed belt conveyors continues to grow, manufacturers are investing in research and development to create innovative surface materials that enhance performance, efficiency, and sustainability. This includes the development of eco-friendly materials that reduce the environmental impact of conveyor systems, as well as advanced coatings that improve resistance to wear and corrosion. The ongoing advancements in material technology are expected to drive the evolution of slider bed belt conveyors, offering businesses more options to optimize their material handling processes.

Packaging, Shipping, Warehousing, Others in the Slider Bed Belt Conveyor - Global Market:

Slider Bed Belt Conveyors are extensively used in various sectors, including packaging, shipping, warehousing, and others, due to their versatility and efficiency. In the packaging industry, these conveyors play a crucial role in streamlining the movement of products through different stages of the packaging process. They facilitate the smooth transfer of goods from one station to another, ensuring that packaging operations are conducted efficiently and without interruptions. The ability to handle a wide range of product sizes and weights makes slider bed belt conveyors an ideal choice for packaging lines, where speed and precision are essential. In the shipping industry, slider bed belt conveyors are used to transport goods from storage areas to loading docks, enabling quick and efficient loading and unloading of shipments. Their ability to handle large volumes of goods with minimal manual intervention helps reduce labor costs and improve turnaround times, making them an indispensable tool in logistics and distribution centers. In warehousing, slider bed belt conveyors are used to optimize the storage and retrieval of goods, facilitating the efficient movement of products within the warehouse. They help reduce the time and effort required to move goods from one location to another, improving overall productivity and reducing the risk of damage to products. Beyond these sectors, slider bed belt conveyors are also used in various other industries, such as agriculture, automotive, and manufacturing, where they contribute to the efficient handling of materials and products. Their adaptability to different environments and applications makes them a valuable asset for businesses looking to improve their operational efficiency and reduce costs. As industries continue to evolve and demand more efficient material handling solutions, the use of slider bed belt conveyors is expected to increase, driving further innovation and growth in the global market.

Slider Bed Belt Conveyor - Global Market Outlook:

The global market for Slider Bed Belt Conveyors was valued at approximately US$ 300.8 million in 2023, with projections indicating a growth to US$ 369.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.0% from 2024 to 2030. This growth is largely attributed to the increasing automation of manufacturing and distribution operations, where slider bed belt conveyors are being integrated with advanced technologies such as robotic arms and sensors. These integrations are designed to enhance operational efficiency and reduce labor costs, making slider bed belt conveyors an attractive option for businesses looking to optimize their material handling processes. The ability to seamlessly integrate with other equipment allows these conveyors to adapt to the changing needs of industries, providing a flexible and efficient solution for transporting goods. As businesses continue to seek ways to improve productivity and reduce costs, the demand for slider bed belt conveyors is expected to rise, driving further growth in the global market. The ongoing advancements in technology and the increasing focus on automation are likely to play a significant role in shaping the future of the slider bed belt conveyor market, offering innovative solutions to meet the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Slider Bed Belt Conveyor - Market |

| Forecasted market size in 2030 | US$ 369.9 million |

| CAGR | 3.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Titan Industries, Jorgensen Conveyor, Smalis Conveyors, Universal Industries, Speedrack West, Roach Conveyors, LEWCO, Hytrol, Taylor Material Handling and Conveyor, Tuffman, Conveyer and Caster, Rolmaster, PRS Group, Endura Veyor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |