What is PGM Refining - Global Market?

PGM refining, or Platinum Group Metals refining, is a crucial process in the global market that involves the extraction and purification of precious metals such as platinum, palladium, rhodium, iridium, osmium, and ruthenium. These metals are highly valued for their unique properties, including resistance to corrosion, high melting points, and excellent catalytic abilities. The refining process is essential because it transforms raw materials into pure, usable forms that can be utilized in various industries. The global market for PGM refining is driven by the demand for these metals in automotive catalytic converters, electronics, jewelry, and chemical industries. The refining process involves complex chemical and physical methods to separate and purify these metals from mined ores or recycled materials. As industries continue to innovate and expand, the need for efficient and environmentally friendly refining processes becomes increasingly important. The market is also influenced by factors such as technological advancements, environmental regulations, and the availability of raw materials. Overall, PGM refining plays a vital role in meeting the global demand for these precious metals, supporting various industrial applications, and contributing to economic growth.

Pyrometallurgical Method, Hydrometallurgical Method, Others in the PGM Refining - Global Market:

The PGM refining process can be broadly categorized into three main methods: pyrometallurgical, hydrometallurgical, and other specialized techniques. The pyrometallurgical method involves high-temperature processes to extract and refine PGMs from ores or recycled materials. This method typically includes smelting, where the material is heated to a molten state, allowing the separation of metals based on their melting points. The molten material is then subjected to further refining processes, such as converting and electrorefining, to achieve the desired purity levels. Pyrometallurgical methods are known for their efficiency in handling large volumes of material and their ability to recover a wide range of metals. However, they also require significant energy input and can have environmental impacts due to emissions and waste generation. On the other hand, the hydrometallurgical method involves the use of aqueous solutions to dissolve and separate PGMs from ores or recycled materials. This method typically includes leaching, where the material is treated with chemical solutions to dissolve the desired metals. The dissolved metals are then recovered through processes such as precipitation, solvent extraction, or ion exchange. Hydrometallurgical methods are often favored for their lower energy requirements and reduced environmental impact compared to pyrometallurgical methods. They also offer greater selectivity and control over the refining process, allowing for the recovery of specific metals with high purity. However, these methods can be slower and may require the use of hazardous chemicals, necessitating careful handling and disposal. In addition to these primary methods, there are other specialized techniques used in PGM refining, such as bioleaching and plasma arc smelting. Bioleaching involves the use of microorganisms to facilitate the extraction of metals from ores, offering a more environmentally friendly alternative to traditional methods. Plasma arc smelting uses high-energy plasma to melt and refine metals, providing a highly efficient and precise refining process. These specialized techniques are often used in conjunction with pyrometallurgical and hydrometallurgical methods to optimize the refining process and achieve the desired purity levels. Overall, the choice of refining method depends on various factors, including the type of material being processed, the desired purity levels, and environmental considerations. Each method has its advantages and limitations, and the global market for PGM refining continues to evolve as new technologies and processes are developed to meet the growing demand for these precious metals.

Dental Industry, Jewelry Industry, Chemical Industry, Others in the PGM Refining - Global Market:

The usage of PGM refining in various industries highlights the versatility and importance of these precious metals in the global market. In the dental industry, PGMs are used in the production of dental alloys and prosthetics due to their biocompatibility, corrosion resistance, and strength. These metals provide durable and long-lasting solutions for dental restorations, ensuring patient safety and comfort. The jewelry industry is another significant consumer of PGMs, particularly platinum and palladium, which are prized for their luster, durability, and rarity. These metals are used to create high-quality, luxurious jewelry pieces that are both aesthetically pleasing and valuable. The chemical industry relies on PGMs for their catalytic properties, which are essential in various chemical reactions and processes. PGMs are used in the production of fertilizers, plastics, and pharmaceuticals, among other products, due to their ability to accelerate chemical reactions and improve efficiency. Additionally, PGMs play a crucial role in the automotive industry, where they are used in catalytic converters to reduce harmful emissions from vehicles. This application is particularly important in meeting environmental regulations and reducing the impact of transportation on air quality. Beyond these industries, PGMs are also used in electronics, glass manufacturing, and fuel cells, showcasing their wide-ranging applications and significance in modern technology. The demand for PGMs in these industries drives the global market for PGM refining, as companies seek to obtain high-purity metals for their products and processes. As industries continue to innovate and develop new applications for PGMs, the importance of efficient and sustainable refining processes becomes increasingly apparent. The global market for PGM refining is poised to grow as these industries expand and the demand for high-quality, refined PGMs continues to rise.

PGM Refining - Global Market Outlook:

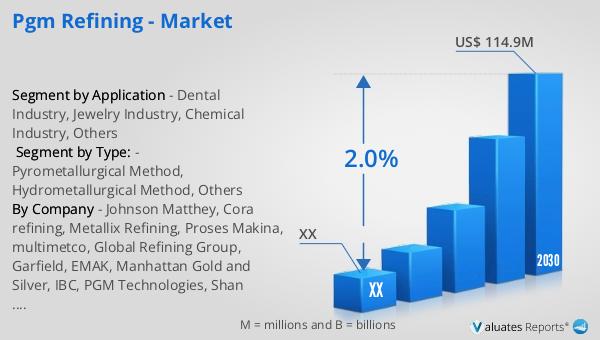

In 2023, the global market for PGM refining was valued at approximately US$ 100 million. Looking ahead, it is anticipated that this market will experience growth, reaching an adjusted size of US$ 114.9 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 2.0% during the forecast period from 2024 to 2030. This steady growth can be attributed to several factors, including the increasing demand for PGMs across various industries such as automotive, electronics, and jewelry. As these industries continue to expand and innovate, the need for high-quality, refined PGMs is expected to rise, driving the market forward. Additionally, advancements in refining technologies and processes are likely to contribute to the market's growth by improving efficiency and reducing environmental impact. The market outlook also reflects the importance of PGMs in meeting global sustainability goals, as these metals play a crucial role in reducing emissions and enhancing the performance of various products. Overall, the PGM refining market is poised for steady growth, supported by the ongoing demand for these valuable metals and the continuous development of refining technologies.

| Report Metric | Details |

| Report Name | PGM Refining - Market |

| Forecasted market size in 2030 | US$ 114.9 million |

| CAGR | 2.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Johnson Matthey, Cora refining, Metallix Refining, Proses Makina, multimetco, Global Refining Group, Garfield, EMAK, Manhattan Gold and Silver, IBC, PGM Technologies, Shan Pornam Metals, BASF, MKS PAMP, SCANACON, Argen, PMR, archenterprises |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |