What is SCARA Material Handling Robot - Global Market?

SCARA (Selective Compliance Assembly Robot Arm) material handling robots are a specialized type of industrial robot designed for high-speed and precision tasks in manufacturing and assembly lines. These robots are characterized by their unique arm design, which allows for selective compliance in the horizontal plane, making them ideal for tasks that require fast and precise movements. The global market for SCARA material handling robots is driven by the increasing demand for automation in various industries, including automotive, electronics, and pharmaceuticals. These robots are particularly valued for their ability to perform repetitive tasks with high accuracy, reducing the need for human intervention and increasing overall productivity. The market is also influenced by advancements in robotic technology, such as improved sensors and control systems, which enhance the capabilities of SCARA robots. As industries continue to seek ways to improve efficiency and reduce costs, the demand for SCARA material handling robots is expected to grow, with manufacturers focusing on developing more versatile and cost-effective models to meet the diverse needs of different sectors.

< 5 Kg, 5 - 10 Kg, > 10 Kg in the SCARA Material Handling Robot - Global Market:

In the global market for SCARA material handling robots, the categorization based on payload capacity is crucial for understanding their applications and demand. Robots with a payload capacity of less than 5 kg are typically used in industries where precision and speed are more critical than the weight of the items being handled. These robots are often employed in the electronics industry for tasks such as assembling small components or handling delicate parts. Their lightweight design allows for rapid movements, making them ideal for high-speed production lines. On the other hand, SCARA robots with a payload capacity between 5 to 10 kg are more versatile and can handle a wider range of tasks. These robots are commonly used in the automotive and packaging industries, where they are required to handle slightly heavier components or products. Their ability to balance speed and strength makes them suitable for tasks such as assembling car parts or packaging goods. Lastly, SCARA robots with a payload capacity of more than 10 kg are designed for heavy-duty applications. These robots are often found in industries such as metal and machinery, where they are used to handle large and heavy components. Their robust design and powerful motors enable them to perform tasks that require significant force, such as welding or material handling in harsh environments. The demand for these robots is driven by industries that require automation solutions capable of handling heavy loads while maintaining precision and efficiency. Overall, the global market for SCARA material handling robots is diverse, with different payload capacities catering to the specific needs of various industries. As technology continues to advance, manufacturers are likely to develop more specialized robots to meet the growing demand for automation across different sectors.

Automotive, Chemical, Rubber and Plastic, Electrical and Electronics, Metal and Machinery, Food, Beverages and Pharmaceuticals, Others in the SCARA Material Handling Robot - Global Market:

SCARA material handling robots are widely used across various industries due to their versatility and efficiency. In the automotive industry, these robots are employed for tasks such as assembling car parts, painting, and welding. Their ability to perform repetitive tasks with high precision makes them ideal for the automotive sector, where consistency and accuracy are crucial. In the chemical, rubber, and plastic industries, SCARA robots are used for handling hazardous materials, mixing chemicals, and assembling plastic components. Their ability to operate in harsh environments and handle delicate materials makes them valuable assets in these industries. In the electrical and electronics sector, SCARA robots are used for assembling circuit boards, soldering components, and testing electronic devices. Their speed and precision are essential for the high-volume production lines typical in this industry. In the metal and machinery industry, SCARA robots are used for tasks such as welding, cutting, and assembling metal parts. Their robust design and ability to handle heavy loads make them suitable for these demanding applications. In the food, beverages, and pharmaceuticals industries, SCARA robots are used for packaging, sorting, and quality control. Their ability to handle delicate products with care and maintain hygiene standards is crucial in these sectors. Overall, the versatility and efficiency of SCARA material handling robots make them indispensable in various industries, driving their demand in the global market.

SCARA Material Handling Robot - Global Market Outlook:

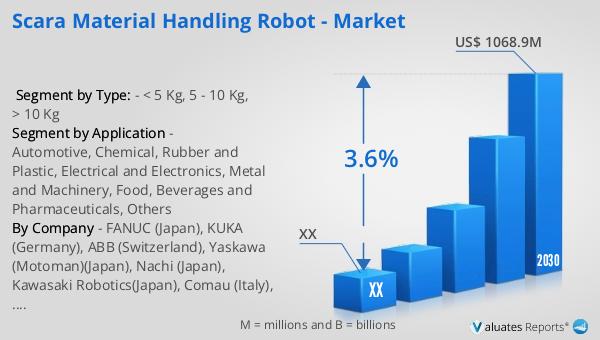

The global market for SCARA material handling robots was valued at approximately $837.4 million in 2023. It is projected to grow to a revised size of $1,068.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for automation solutions across various industries, driven by the need for improved efficiency and productivity. The North American market for SCARA material handling robots also shows promising growth potential, although specific figures for this region were not provided. The overall market outlook suggests that as industries continue to adopt automation technologies, the demand for SCARA robots will continue to rise. Manufacturers are likely to focus on developing more advanced and cost-effective models to cater to the diverse needs of different sectors. The market's growth is also supported by technological advancements, such as improved sensors and control systems, which enhance the capabilities of SCARA robots. As a result, the global market for SCARA material handling robots is expected to witness steady growth in the coming years, driven by the increasing adoption of automation solutions across various industries.

| Report Metric | Details |

| Report Name | SCARA Material Handling Robot - Market |

| Forecasted market size in 2030 | US$ 1068.9 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | FANUC (Japan), KUKA (Germany), ABB (Switzerland), Yaskawa (Motoman)(Japan), Nachi (Japan), Kawasaki Robotics(Japan), Comau (Italy), EPSON Robots (Japan), Staubli (Switzerland), Omron Adept Technologies (US), DENSO Robotics (Japan), OTC Daihen (Japan), Toshiba (Japan), Mitsubishi Electric (Japan), Universal Robots (Denmark), Hyundai Robotics (Korea), Siasun (China), Anhui EFORT Intelligent Equipment (China), Estun Automation (China), Guangzhou CNC Equipment (China), STEP Electric Corporation (China) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |