What is Carbide Tipped Bandsaw Blade - Global Market?

Carbide tipped bandsaw blades are specialized cutting tools used in various industries for their durability and precision. These blades are designed with carbide tips, which are known for their hardness and ability to maintain a sharp edge longer than traditional steel blades. This makes them ideal for cutting through tough materials such as metals, hardwoods, and composites. The global market for carbide tipped bandsaw blades is driven by the demand for efficient and long-lasting cutting solutions in industries like construction, automotive, and manufacturing. As industries continue to seek ways to improve productivity and reduce costs, the adoption of carbide tipped bandsaw blades is expected to grow. These blades offer a cost-effective solution by reducing the frequency of blade changes and minimizing downtime. Additionally, advancements in manufacturing technologies have led to the development of more sophisticated carbide tipped bandsaw blades, further enhancing their performance and expanding their applications. The global market is characterized by a diverse range of products catering to different cutting needs, with manufacturers focusing on innovation to meet the evolving demands of end-users. As a result, the carbide tipped bandsaw blade market is poised for steady growth in the coming years.

Below 27mm, 27-41mm, Above 41mm in the Carbide Tipped Bandsaw Blade - Global Market:

Carbide tipped bandsaw blades are available in various sizes, each catering to specific cutting requirements. The size of the blade is typically determined by its width, which affects its cutting capacity and application. In the global market, these blades are categorized into three main size segments: below 27mm, 27-41mm, and above 41mm. Blades below 27mm are generally used for intricate and precise cutting tasks. They are favored in industries where detailed work is required, such as in fine woodworking or delicate metalworking projects. These smaller blades offer greater flexibility and maneuverability, allowing for intricate cuts and detailed work. The 27-41mm segment represents a versatile range of blades that are suitable for a wide array of applications. These blades strike a balance between precision and power, making them ideal for medium-duty tasks in industries like construction and general manufacturing. They are often used for cutting medium-thickness materials, providing a good compromise between speed and accuracy. Blades above 41mm are designed for heavy-duty applications where power and durability are paramount. These larger blades are used in industries that require cutting through thick and dense materials, such as in the construction of large structures or in heavy machinery manufacturing. Their robust design allows them to withstand the rigors of demanding cutting tasks, making them indispensable in settings where efficiency and reliability are critical. The global market for carbide tipped bandsaw blades is influenced by the specific needs of these different size segments, with manufacturers continually innovating to enhance blade performance and meet the diverse requirements of end-users. As industries evolve and new materials are introduced, the demand for specialized blades in each size category is expected to grow, driving further advancements in blade technology and expanding the market's reach.

Ferrous metallurgy industrial, Machining, Automobile industrial, Aviation, Other in the Carbide Tipped Bandsaw Blade - Global Market:

Carbide tipped bandsaw blades are utilized across various industries due to their superior cutting capabilities and durability. In the ferrous metallurgy industry, these blades are essential for cutting through tough metals like steel and iron. Their ability to maintain a sharp edge even after prolonged use makes them ideal for high-volume production environments where precision and efficiency are crucial. The machining industry also benefits significantly from carbide tipped bandsaw blades. These blades are used to cut a wide range of materials, including metals, plastics, and composites. Their versatility and long-lasting performance make them a preferred choice for manufacturers looking to optimize their cutting processes and reduce tool changeover times. In the automobile industry, carbide tipped bandsaw blades play a vital role in the production of vehicle components. They are used to cut various materials, including metals and composites, ensuring that parts are manufactured to precise specifications. The aviation industry also relies on these blades for their ability to cut through advanced materials used in aircraft construction. The precision and durability of carbide tipped bandsaw blades are critical in ensuring the safety and reliability of aircraft components. Additionally, these blades find applications in other industries, such as construction and woodworking, where their ability to cut through tough materials with ease is highly valued. The global market for carbide tipped bandsaw blades is driven by the diverse applications of these blades across different industries, with manufacturers continually developing new products to meet the evolving needs of end-users. As industries continue to seek ways to improve efficiency and reduce costs, the demand for carbide tipped bandsaw blades is expected to grow, further solidifying their position as an essential tool in modern manufacturing.

Carbide Tipped Bandsaw Blade - Global Market Outlook:

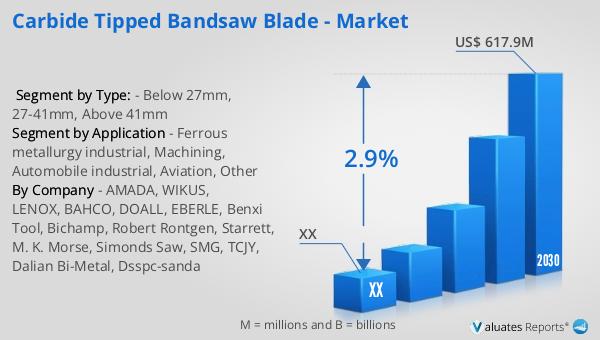

The global market for carbide tipped bandsaw blades was valued at approximately $507.3 million in 2023. It is projected to grow to a revised size of $617.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.9% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and durable cutting solutions across various industries. The North American market, in particular, is expected to experience significant growth during this period. Although specific figures for the North American market were not provided, it is anticipated that the region will see a steady increase in the adoption of carbide tipped bandsaw blades. This growth can be attributed to the robust industrial sector in North America, which continually seeks advanced tools to enhance productivity and reduce operational costs. The market outlook suggests that as industries evolve and new materials are introduced, the demand for carbide tipped bandsaw blades will continue to rise. Manufacturers are likely to focus on innovation and the development of new products to meet the changing needs of end-users, further driving market growth. The steady increase in market size underscores the importance of carbide tipped bandsaw blades as a critical component in modern manufacturing processes.

| Report Metric | Details |

| Report Name | Carbide Tipped Bandsaw Blade - Market |

| Forecasted market size in 2030 | US$ 617.9 million |

| CAGR | 2.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AMADA, WIKUS, LENOX, BAHCO, DOALL, EBERLE, Benxi Tool, Bichamp, Robert Rontgen, Starrett, M. K. Morse, Simonds Saw, SMG, TCJY, Dalian Bi-Metal, Dsspc-sanda |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |