What is RTD Thermowells - Global Market?

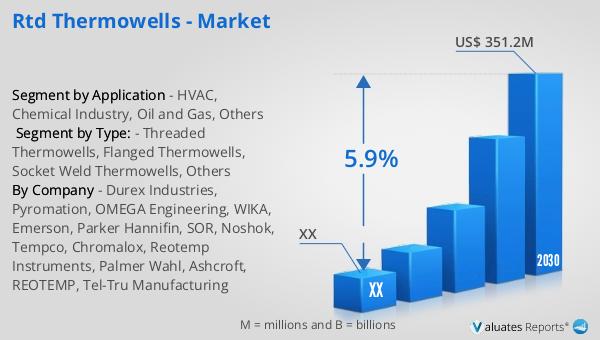

RTD thermowells are essential components in the global market, serving as protective devices for resistance temperature detectors (RTDs) used in various temperature measurement applications. These devices are designed to shield RTDs from harsh environmental conditions, ensuring accurate and reliable temperature readings. The global market for RTD thermowells was valued at approximately US$ 215 million in 2023. It is projected to grow significantly, reaching an estimated size of US$ 351.2 million by 2030, with a compound annual growth rate (CAGR) of 5.9% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for precise temperature measurement in industries such as HVAC, chemical, and oil and gas, where maintaining optimal temperature conditions is crucial for operational efficiency and safety. RTD thermowells are available in various types, including threaded, flanged, and socket weld, each offering unique benefits and applications. Their robust construction and ability to withstand extreme temperatures and pressures make them indispensable in industrial settings, contributing to their expanding market presence. As industries continue to prioritize accuracy and reliability in temperature monitoring, the demand for RTD thermowells is expected to rise, further fueling market growth.

Threaded Thermowells, Flanged Thermowells, Socket Weld Thermowells, Others in the RTD Thermowells - Global Market:

Threaded thermowells are a popular choice in the RTD thermowells market due to their ease of installation and versatility. These thermowells are designed with threads that allow them to be screwed directly into a process connection, making them suitable for applications where quick and straightforward installation is required. They are commonly used in industries such as HVAC, chemical, and oil and gas, where frequent maintenance and replacement of temperature sensors are necessary. Threaded thermowells provide a secure fit, ensuring that the RTD sensor remains in place even under high-pressure conditions. Their design also allows for easy removal and replacement, reducing downtime and maintenance costs. Flanged thermowells, on the other hand, are preferred in applications where a more robust and secure connection is needed. These thermowells feature a flange that is bolted to a mating flange on the process equipment, providing a tight seal that prevents leaks and ensures accurate temperature measurement. Flanged thermowells are ideal for high-pressure and high-temperature applications, such as those found in the oil and gas industry, where safety and reliability are paramount. Socket weld thermowells offer a different approach, with a design that allows them to be welded directly into the process piping. This provides a permanent and leak-proof connection, making them suitable for applications where long-term reliability is essential. Socket weld thermowells are often used in chemical processing plants, where the risk of leaks must be minimized to ensure safety and prevent contamination. Other types of RTD thermowells, such as sanitary and vanstone thermowells, cater to specific industry needs, offering unique features and benefits. Sanitary thermowells, for example, are designed for use in the food and beverage industry, where hygiene and cleanliness are critical. They feature smooth surfaces and crevice-free designs that prevent the buildup of bacteria and other contaminants. Vanstone thermowells, meanwhile, are used in applications where thermal expansion is a concern, as their design allows for movement without compromising the integrity of the connection. Each type of RTD thermowell offers distinct advantages, making them suitable for a wide range of applications across various industries. As the demand for precise temperature measurement continues to grow, the market for RTD thermowells is expected to expand, driven by the need for reliable and accurate temperature monitoring solutions.

HVAC, Chemical Industry, Oil and Gas, Others in the RTD Thermowells - Global Market:

RTD thermowells play a crucial role in various industries, providing reliable temperature measurement solutions that are essential for maintaining optimal operating conditions. In the HVAC industry, RTD thermowells are used to monitor and control the temperature of air and water systems, ensuring efficient heating, ventilation, and air conditioning. Accurate temperature measurement is vital for maintaining indoor comfort levels and optimizing energy consumption, making RTD thermowells an indispensable component in modern HVAC systems. In the chemical industry, RTD thermowells are used to monitor the temperature of chemical reactions and processes, ensuring that they occur within the desired temperature range. Precise temperature control is critical for maintaining product quality and safety, as deviations can lead to undesirable chemical reactions or product defects. RTD thermowells provide the accuracy and reliability needed to ensure consistent temperature monitoring, helping chemical manufacturers maintain high standards of quality and safety. In the oil and gas industry, RTD thermowells are used to monitor the temperature of pipelines, storage tanks, and processing equipment, ensuring safe and efficient operation. Accurate temperature measurement is essential for preventing equipment failures and ensuring the safe transport and storage of oil and gas products. RTD thermowells provide the durability and reliability needed to withstand the harsh conditions often encountered in the oil and gas industry, making them a critical component in temperature monitoring systems. Other industries, such as food and beverage, pharmaceuticals, and power generation, also rely on RTD thermowells for accurate temperature measurement. In the food and beverage industry, RTD thermowells are used to monitor the temperature of cooking and storage processes, ensuring food safety and quality. In the pharmaceutical industry, they are used to monitor the temperature of drug manufacturing processes, ensuring that products are produced within the required temperature range. In power generation, RTD thermowells are used to monitor the temperature of turbines and other equipment, ensuring efficient and reliable operation. As industries continue to prioritize accuracy and reliability in temperature monitoring, the demand for RTD thermowells is expected to grow, driving market expansion.

RTD Thermowells - Global Market Outlook:

English: #RTDThermowells #TemperatureMeasurement #IndustrialApplications #HVAC #ChemicalIndustry #OilAndGas #MarketGrowth #ThermowellTypes #GlobalMarket #ReliableMonitoring

| Report Metric | Details |

| Report Name | RTD Thermowells - Market |

| Forecasted market size in 2030 | US$ 351.2 million |

| CAGR | 5.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Durex Industries, Pyromation, OMEGA Engineering, WIKA, Emerson, Parker Hannifin, SOR, Noshok, Tempco, Chromalox, Reotemp Instruments, Palmer Wahl, Ashcroft, REOTEMP, Tel-Tru Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |