What is Plastic Embossing Roller - Global Market?

Plastic embossing rollers are specialized tools used in various industries to create textured patterns on plastic surfaces. These rollers are integral to the manufacturing process, where they emboss intricate designs onto plastic sheets or films, enhancing both their aesthetic appeal and functional properties. The global market for plastic embossing rollers is driven by the increasing demand for customized and high-quality plastic products across different sectors. These rollers are crafted from durable materials to withstand high pressure and temperature, ensuring precise and consistent embossing results. The market is characterized by technological advancements that have led to the development of more efficient and versatile embossing rollers. Manufacturers are focusing on innovation to cater to the diverse needs of industries such as packaging, automotive, and consumer goods. The growing emphasis on sustainability and eco-friendly materials is also influencing the market, as companies seek to reduce their environmental footprint while maintaining product quality. Overall, the plastic embossing roller market is poised for growth, driven by the rising demand for aesthetically pleasing and functionally superior plastic products across the globe.

PVC, PET, Others in the Plastic Embossing Roller - Global Market:

In the realm of plastic embossing rollers, materials like PVC (Polyvinyl Chloride), PET (Polyethylene Terephthalate), and others play a crucial role in determining the quality and application of the embossed products. PVC is a versatile plastic known for its durability, flexibility, and resistance to environmental degradation. It is widely used in the production of embossing rollers due to its ability to withstand high temperatures and pressures, making it ideal for creating intricate patterns on plastic surfaces. PVC embossing rollers are commonly used in industries such as packaging, automotive, and construction, where durability and precision are paramount. On the other hand, PET is a type of polyester that is valued for its strength, transparency, and recyclability. PET embossing rollers are often used in the food and beverage industry, where the clarity and safety of packaging materials are critical. The recyclability of PET also aligns with the growing demand for sustainable and eco-friendly products, making it a popular choice among manufacturers. Besides PVC and PET, other materials like polycarbonate, polypropylene, and ABS (Acrylonitrile Butadiene Styrene) are also used in the production of embossing rollers. These materials offer unique properties that cater to specific industry needs, such as impact resistance, chemical resistance, and thermal stability. Polycarbonate embossing rollers, for instance, are known for their high impact resistance and optical clarity, making them suitable for applications in the electronics and automotive industries. Polypropylene, with its excellent chemical resistance and low density, is often used in the packaging and medical industries. ABS, on the other hand, is favored for its toughness and ease of processing, making it a popular choice for consumer goods and automotive applications. The choice of material for plastic embossing rollers depends on various factors, including the intended application, desired properties, and cost considerations. Manufacturers are continually exploring new materials and technologies to enhance the performance and efficiency of embossing rollers. The development of advanced materials with improved properties, such as enhanced durability, heat resistance, and environmental sustainability, is a key focus area for the industry. As the demand for high-quality and customized plastic products continues to grow, the market for plastic embossing rollers is expected to expand, driven by innovations in material science and manufacturing processes.

Paper Industry, Rubber Industry, Textile Industry, Others in the Plastic Embossing Roller - Global Market:

Plastic embossing rollers find extensive usage across various industries, including the paper, rubber, and textile sectors, among others. In the paper industry, embossing rollers are used to create textured patterns on paper products, enhancing their visual appeal and tactile experience. These rollers are essential in the production of decorative papers, packaging materials, and stationery items, where the embossed designs add value and differentiation. The ability to produce intricate and consistent patterns makes embossing rollers a valuable tool for paper manufacturers seeking to offer unique and high-quality products. In the rubber industry, embossing rollers are used to imprint patterns on rubber sheets and products, such as floor mats, seals, and gaskets. The embossed patterns not only enhance the aesthetic appeal of rubber products but also improve their functional properties, such as grip and traction. The durability and precision of embossing rollers make them ideal for use in the rubber industry, where consistent quality and performance are critical. In the textile industry, embossing rollers are used to create textured patterns on fabrics and textiles, adding depth and dimension to the final products. These rollers are commonly used in the production of upholstery fabrics, clothing, and home textiles, where the embossed designs contribute to the overall aesthetic and tactile experience. The versatility of embossing rollers allows textile manufacturers to experiment with different patterns and textures, catering to diverse consumer preferences and market trends. Beyond these industries, embossing rollers are also used in other sectors, such as plastics, leather, and metalworking, where they play a crucial role in enhancing the appearance and functionality of products. The ability to customize embossing rollers to suit specific applications and materials makes them a versatile and indispensable tool in modern manufacturing. As industries continue to evolve and innovate, the demand for high-quality and customized embossed products is expected to drive the growth of the plastic embossing roller market.

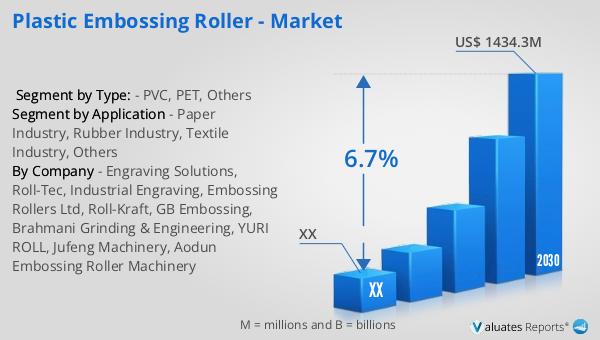

Plastic Embossing Roller - Global Market Outlook:

The global market for plastic embossing rollers was valued at approximately $822 million in 2023. It is projected to grow significantly, reaching an estimated size of $1,434.3 million by 2030, with a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-quality and customized embossed plastic products across various industries. The North American market for plastic embossing rollers also shows promising growth potential, although specific figures for this region were not provided. The anticipated growth in this market can be attributed to the rising demand for aesthetically pleasing and functionally superior plastic products, as well as advancements in embossing technology. As industries continue to innovate and seek sustainable solutions, the market for plastic embossing rollers is expected to expand, driven by the need for efficient and versatile embossing tools. The focus on sustainability and eco-friendly materials is also likely to influence market dynamics, as companies strive to reduce their environmental impact while maintaining product quality. Overall, the plastic embossing roller market is poised for growth, supported by technological advancements and the increasing demand for high-quality embossed products.

| Report Metric | Details |

| Report Name | Plastic Embossing Roller - Market |

| Forecasted market size in 2030 | US$ 1434.3 million |

| CAGR | 6.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Engraving Solutions, Roll-Tec, Industrial Engraving, Embossing Rollers Ltd, Roll-Kraft, GB Embossing, Brahmani Grinding & Engineering, YURI ROLL, Jufeng Machinery, Aodun Embossing Roller Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |