What is Metal Embossing Roller - Global Market?

Metal embossing rollers are specialized tools used in various industries to create raised or recessed designs on metal surfaces. These rollers are integral to processes that require intricate patterns, textures, or logos to be embossed onto metal sheets or coils. The global market for metal embossing rollers is driven by the demand for aesthetically appealing and functional metal products across sectors such as automotive, construction, and consumer goods. These rollers are crafted from high-quality materials to withstand the pressure and wear of continuous use, ensuring precision and durability. The market is characterized by technological advancements that enhance the efficiency and versatility of embossing processes. As industries increasingly seek customized and high-quality finishes, the demand for metal embossing rollers is expected to grow. This growth is further supported by the expansion of manufacturing activities and the rising trend of decorative metal applications. The global market is competitive, with numerous players offering a range of products tailored to specific industrial needs. Companies are focusing on innovation and the development of advanced materials to maintain a competitive edge. Overall, the metal embossing roller market is poised for steady growth, driven by its essential role in modern manufacturing and design.

Stainless, Aluminum, Others in the Metal Embossing Roller - Global Market:

In the global market for metal embossing rollers, materials such as stainless steel, aluminum, and others play a crucial role in determining the performance and application of these tools. Stainless steel embossing rollers are highly favored for their strength, corrosion resistance, and ability to maintain sharpness over prolonged use. These properties make them ideal for applications requiring high precision and durability, such as in the automotive and aerospace industries. Stainless steel rollers are also preferred in environments where hygiene is paramount, such as in food processing and pharmaceuticals, due to their easy-to-clean nature. On the other hand, aluminum embossing rollers are valued for their lightweight and excellent thermal conductivity. These characteristics make them suitable for applications where weight reduction is critical, such as in the packaging industry. Aluminum rollers are also used in the production of decorative finishes on consumer goods, where their ability to produce fine details is highly appreciated. Beyond stainless steel and aluminum, other materials like brass, copper, and various alloys are used in the production of embossing rollers. These materials are selected based on specific requirements such as conductivity, malleability, and aesthetic appeal. For instance, brass rollers are often used in applications where a warm, golden finish is desired, while copper rollers are chosen for their excellent electrical conductivity. The choice of material is influenced by factors such as the type of metal being embossed, the desired finish, and the operational environment. Manufacturers in the global market are continually exploring new materials and coatings to enhance the performance and lifespan of embossing rollers. This includes the development of composite materials that combine the best properties of different metals, offering improved wear resistance and reduced maintenance costs. As industries evolve and new applications for embossed metals emerge, the demand for diverse and innovative embossing roller materials is expected to rise. The global market for metal embossing rollers is thus characterized by a dynamic interplay of material science and industrial needs, driving continuous innovation and growth.

Paper Industry, Rubber Industry, Textile Industry, Others in the Metal Embossing Roller - Global Market:

Metal embossing rollers find extensive usage across various industries, each leveraging the unique capabilities of these tools to enhance their products and processes. In the paper industry, embossing rollers are used to create textures and patterns on paper products, adding both aesthetic appeal and functional benefits. For instance, embossed paper can offer improved grip, increased absorbency, or enhanced visual appeal, making it popular in products like napkins, tissues, and decorative papers. The precision and versatility of embossing rollers allow manufacturers to produce intricate designs that meet consumer demands for unique and high-quality paper products. In the rubber industry, embossing rollers are employed to imprint patterns and textures onto rubber sheets and products. This is particularly important in the production of items like floor mats, conveyor belts, and seals, where the embossed patterns can improve traction, reduce slippage, or enhance sealing capabilities. The ability to customize patterns according to specific requirements makes embossing rollers indispensable in the rubber industry. Similarly, in the textile industry, embossing rollers are used to create raised patterns on fabrics, adding texture and depth to the material. This process is widely used in the production of upholstery, clothing, and home textiles, where the tactile and visual qualities of embossed fabrics are highly valued. The versatility of embossing rollers allows textile manufacturers to experiment with different patterns and designs, catering to diverse consumer preferences. Beyond these industries, metal embossing rollers are also used in sectors such as packaging, where they help create decorative and functional patterns on packaging materials. This can enhance the visual appeal of packaging, making products more attractive to consumers. Additionally, embossing rollers are used in the production of metal foils and films, where they help create intricate designs and textures that are used in various applications, from electronics to decorative arts. The global market for metal embossing rollers is thus driven by their wide-ranging applications and the growing demand for customized and high-quality products across industries. As technology advances and new materials are developed, the capabilities and applications of embossing rollers are expected to expand, further fueling market growth.

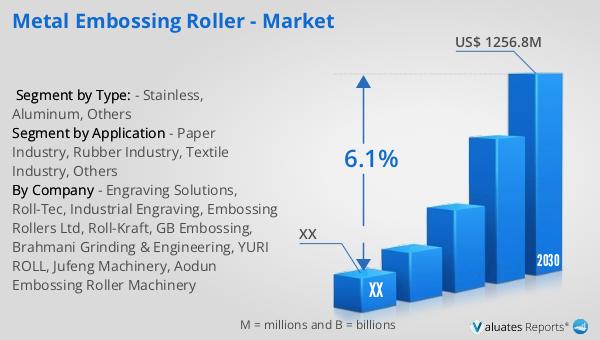

Metal Embossing Roller - Global Market Outlook:

The global market for metal embossing rollers was valued at approximately $827 million in 2023. It is projected to grow to a revised size of around $1,256.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.1% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for metal embossing rollers across various industries, driven by the need for high-quality and customized metal products. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The anticipated expansion in the North American market underscores the region's robust manufacturing sector and the growing adoption of advanced manufacturing technologies. The overall market outlook suggests a positive trajectory for the metal embossing roller industry, supported by technological advancements and the rising trend of decorative and functional metal applications. As industries continue to evolve and seek innovative solutions, the demand for metal embossing rollers is likely to increase, contributing to the market's growth. The focus on sustainability and efficiency in manufacturing processes is also expected to drive the adoption of advanced embossing technologies, further boosting market prospects.

| Report Metric | Details |

| Report Name | Metal Embossing Roller - Market |

| Forecasted market size in 2030 | US$ 1256.8 million |

| CAGR | 6.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Engraving Solutions, Roll-Tec, Industrial Engraving, Embossing Rollers Ltd, Roll-Kraft, GB Embossing, Brahmani Grinding & Engineering, YURI ROLL, Jufeng Machinery, Aodun Embossing Roller Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |