What is Oxidation Catalysts - Global Market?

Oxidation catalysts play a crucial role in the global market by facilitating chemical reactions that help reduce harmful emissions from various industrial processes. These catalysts are primarily used to convert pollutants like carbon monoxide, hydrocarbons, and volatile organic compounds into less harmful substances such as carbon dioxide and water. The global market for oxidation catalysts is driven by stringent environmental regulations and the increasing demand for cleaner air and water. Industries such as automotive, chemical manufacturing, and power generation are significant consumers of these catalysts. The market is characterized by continuous innovation and development of advanced catalyst technologies to enhance efficiency and reduce costs. As industries strive to meet environmental standards and reduce their carbon footprint, the demand for oxidation catalysts is expected to grow steadily. The market is also influenced by the availability of raw materials, technological advancements, and the adoption of sustainable practices by industries worldwide. Overall, oxidation catalysts are essential components in the global effort to minimize environmental pollution and promote sustainable industrial practices.

Precious Metals, Special Promoters, Special Binders in the Oxidation Catalysts - Global Market:

Precious metals, special promoters, and special binders are integral components of oxidation catalysts, each playing a unique role in enhancing the catalyst's performance. Precious metals like platinum, palladium, and rhodium are commonly used in oxidation catalysts due to their excellent catalytic properties. These metals facilitate the oxidation of pollutants at lower temperatures, making the process more efficient and cost-effective. The high cost of precious metals is a significant factor in the overall cost of oxidation catalysts, driving research into alternative materials and methods to reduce reliance on these metals. Special promoters are additives that enhance the activity and selectivity of the catalyst. They work by modifying the surface properties of the catalyst, improving its ability to adsorb and react with pollutants. Promoters can also increase the catalyst's resistance to deactivation by impurities, extending its lifespan and reducing maintenance costs. Special binders are used to hold the catalyst components together and provide structural integrity. They ensure that the catalyst maintains its shape and surface area during operation, which is crucial for maintaining its effectiveness. Binders also play a role in the thermal stability of the catalyst, allowing it to withstand high temperatures without degrading. The choice of binders depends on the specific application and operating conditions of the catalyst. In the global market, the development of new materials and formulations for oxidation catalysts is a key area of research and innovation. Companies are investing in the development of catalysts that use less precious metal or alternative materials to reduce costs and improve sustainability. The use of nanotechnology and advanced manufacturing techniques is also being explored to enhance the performance and durability of oxidation catalysts. As environmental regulations become more stringent, the demand for high-performance catalysts that can effectively reduce emissions is expected to increase. This has led to a growing interest in catalysts that can operate under a wider range of conditions and with different types of pollutants. The global market for oxidation catalysts is highly competitive, with numerous players offering a wide range of products and solutions. Companies are focusing on developing customized catalysts tailored to specific industrial applications and customer needs. Collaboration between catalyst manufacturers, research institutions, and end-users is essential for driving innovation and addressing the challenges faced by the industry. Overall, the market for oxidation catalysts is dynamic and evolving, with ongoing research and development efforts aimed at improving performance, reducing costs, and meeting the growing demand for cleaner and more sustainable industrial processes.

Commercial Vehicles, Marine Applications, Others in the Oxidation Catalysts - Global Market:

Oxidation catalysts are widely used in various applications, including commercial vehicles, marine applications, and other industries, to reduce emissions and improve air quality. In commercial vehicles, oxidation catalysts are an essential component of exhaust after-treatment systems. They help convert harmful pollutants such as carbon monoxide, hydrocarbons, and particulate matter into less harmful substances before they are released into the atmosphere. This is particularly important for diesel engines, which are known for their high emissions of nitrogen oxides and particulate matter. The use of oxidation catalysts in commercial vehicles is driven by stringent emission standards and the need to comply with regulations such as the Euro VI and EPA standards. These catalysts help manufacturers meet emission targets while maintaining engine performance and fuel efficiency. In marine applications, oxidation catalysts are used to reduce emissions from ship engines and auxiliary power units. The maritime industry is a significant source of air pollution, with ships emitting large quantities of sulfur oxides, nitrogen oxides, and particulate matter. The International Maritime Organization (IMO) has implemented regulations to limit these emissions, driving the adoption of emission control technologies such as oxidation catalysts. These catalysts help ship operators comply with emission limits while minimizing the impact on engine performance and fuel consumption. In addition to commercial vehicles and marine applications, oxidation catalysts are used in various other industries to control emissions and improve air quality. For example, they are used in power plants to reduce emissions from combustion processes, in chemical manufacturing to control emissions from chemical reactions, and in waste treatment facilities to reduce odors and harmful emissions. The versatility and effectiveness of oxidation catalysts make them a valuable tool for industries seeking to reduce their environmental impact and comply with regulatory requirements. The global market for oxidation catalysts in these applications is driven by the increasing demand for cleaner air and the need to meet stringent emission standards. As industries continue to seek ways to reduce their carbon footprint and improve sustainability, the demand for oxidation catalysts is expected to grow. Companies are investing in research and development to improve the performance and cost-effectiveness of these catalysts, ensuring they remain a viable solution for emission control in various applications. Overall, oxidation catalysts play a critical role in reducing emissions and improving air quality across a wide range of industries, contributing to a cleaner and more sustainable future.

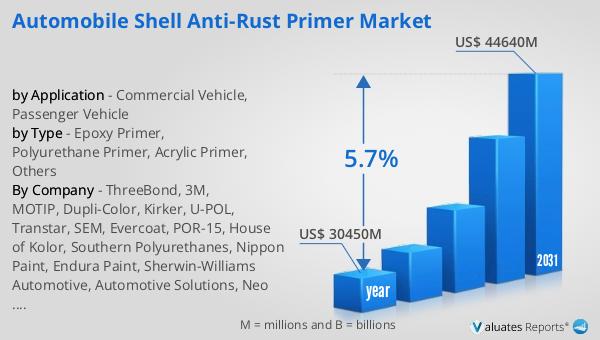

Oxidation Catalysts - Global Market Outlook:

The global market for oxidation catalysts was valued at approximately $15,320 million in 2023, with projections indicating a growth to around $23,130 million by 2030. This growth represents a compound annual growth rate (CAGR) of 6.1% during the forecast period from 2024 to 2030. Catalysts, often referred to as the "chips" of the chemical industry, are vital for enhancing the efficiency of chemical reactions and enabling large-scale production. They are indispensable in various industrial processes, particularly in reducing harmful emissions and promoting cleaner production methods. The increasing demand for oxidation catalysts is driven by the need to comply with stringent environmental regulations and the growing awareness of the importance of reducing air pollution. Industries such as automotive, power generation, and chemical manufacturing are significant consumers of these catalysts, as they seek to minimize their environmental impact and improve sustainability. The market is characterized by continuous innovation and the development of advanced catalyst technologies to enhance performance and reduce costs. As industries strive to meet environmental standards and reduce their carbon footprint, the demand for oxidation catalysts is expected to grow steadily. The market is also influenced by the availability of raw materials, technological advancements, and the adoption of sustainable practices by industries worldwide. Overall, oxidation catalysts are essential components in the global effort to minimize environmental pollution and promote sustainable industrial practices.

| Report Metric | Details |

| Report Name | Oxidation Catalysts - Market |

| Forecasted market size in 2030 | US$ 23130 million |

| CAGR | 6.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BASF, Miratech, Peroxychem, Intellishare Environmental, Dry Systems Technologies, Molecular Products, Advanced Power Systems International, Saint-Gobain, Applied Ceramics, Tann Corporation, Johnson Matthey, Csm Worldwide, Applied Catalysts, Synergy Catalyst, Sunny Metal, B and W Megtec, Berty Reaction Engineers, Hypercat ACP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |