What is Electrospun Nanofiber Catalyst - Global Market?

Electrospun nanofiber catalysts represent a cutting-edge innovation in the field of materials science, offering a unique approach to enhancing chemical reactions. These catalysts are created through a process called electrospinning, which involves using an electric charge to draw very fine fibers from a liquid. The resulting nanofibers have a high surface area-to-volume ratio, making them exceptionally effective at facilitating chemical reactions. This high efficiency is due to the increased surface area available for reactions to occur, which can significantly improve the speed and yield of chemical processes. The global market for electrospun nanofiber catalysts is gaining traction as industries recognize their potential to revolutionize production processes. These catalysts are particularly valuable in applications where traditional catalysts fall short, offering enhanced performance and sustainability. As industries continue to seek more efficient and environmentally friendly solutions, the demand for electrospun nanofiber catalysts is expected to grow, driving innovation and development in this promising field.

Metal-based, Ceramic-based, Polymer-based in the Electrospun Nanofiber Catalyst - Global Market:

Electrospun nanofiber catalysts can be categorized based on the materials used in their production, namely metal-based, ceramic-based, and polymer-based catalysts. Metal-based electrospun nanofiber catalysts are highly sought after due to their excellent conductivity and catalytic properties. Metals such as platinum, palladium, and gold are often used, as they provide superior catalytic activity and stability. These catalysts are particularly effective in applications such as fuel cells and chemical synthesis, where high efficiency and durability are crucial. The high surface area of the nanofibers allows for more active sites, enhancing the overall catalytic performance. Ceramic-based electrospun nanofiber catalysts, on the other hand, are known for their thermal stability and resistance to harsh chemical environments. Materials like titanium dioxide and zirconia are commonly used in these catalysts, making them ideal for high-temperature applications and processes involving corrosive substances. The robustness of ceramic-based catalysts ensures longevity and reliability, making them a preferred choice in industries such as petrochemicals and environmental remediation. Polymer-based electrospun nanofiber catalysts offer a different set of advantages, primarily due to their versatility and ease of modification. Polymers can be engineered to incorporate various functional groups, allowing for tailored catalytic properties. This adaptability makes polymer-based catalysts suitable for a wide range of applications, from drug delivery systems to biodegradable materials. The lightweight nature of polymers also contributes to their appeal, particularly in industries where weight reduction is a priority. Each type of electrospun nanofiber catalyst brings unique benefits to the table, catering to specific industrial needs and driving innovation across multiple sectors. As research and development in this field continue to advance, the potential applications and effectiveness of these catalysts are expected to expand, offering new solutions to complex industrial challenges.

Chemical and Material, Pharmaceuticals, Others in the Electrospun Nanofiber Catalyst - Global Market:

The usage of electrospun nanofiber catalysts spans several key areas, including chemical and material industries, pharmaceuticals, and other sectors. In the chemical and material industries, these catalysts are revolutionizing processes by enhancing reaction rates and yields. Their high surface area and unique structural properties allow for more efficient catalysis, reducing the energy and time required for chemical reactions. This efficiency is particularly beneficial in large-scale production, where even small improvements can lead to significant cost savings. Additionally, the ability to tailor the properties of electrospun nanofiber catalysts makes them ideal for specific applications, such as polymerization and oxidation reactions, where traditional catalysts may not perform as effectively. In the pharmaceutical industry, electrospun nanofiber catalysts are opening new avenues for drug development and delivery. Their high surface area and customizable properties enable precise control over reaction conditions, leading to more efficient synthesis of complex molecules. This precision is crucial in the development of new drugs, where the purity and yield of the final product are of utmost importance. Furthermore, the potential for incorporating active pharmaceutical ingredients directly into the nanofibers offers innovative solutions for drug delivery systems, improving the bioavailability and efficacy of medications. Beyond these industries, electrospun nanofiber catalysts are finding applications in areas such as environmental remediation and energy production. Their ability to facilitate reactions under mild conditions makes them ideal for processes like water purification and carbon capture, where sustainability and efficiency are key concerns. In energy production, these catalysts are being explored for use in fuel cells and batteries, where their high catalytic activity can enhance performance and reduce costs. As industries continue to seek more sustainable and efficient solutions, the versatility and effectiveness of electrospun nanofiber catalysts position them as a valuable tool in addressing complex challenges across various sectors.

Electrospun Nanofiber Catalyst - Global Market Outlook:

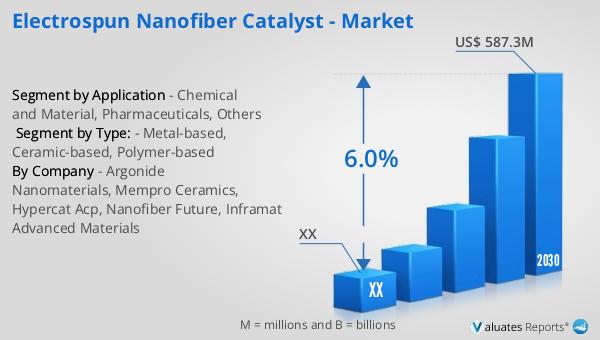

The global market for electrospun nanofiber catalysts was valued at approximately US$ 391 million in 2023, with projections indicating a growth to around US$ 587.3 million by 2030. This represents a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2024 to 2030. Catalysts, often referred to as the "chips" of the chemical industry, play a crucial role in enhancing the efficiency of chemical reactions, thereby facilitating large-scale production. The unique properties of electrospun nanofiber catalysts, such as their high surface area and customizable characteristics, make them particularly effective in improving reaction rates and yields. This efficiency is driving their adoption across various industries, as companies seek to optimize processes and reduce costs. The anticipated growth in the market reflects the increasing recognition of the benefits offered by these advanced catalysts, as well as the ongoing research and development efforts aimed at expanding their applications. As industries continue to prioritize sustainability and efficiency, the demand for electrospun nanofiber catalysts is expected to rise, further fueling market growth and innovation in this dynamic field.

| Report Metric | Details |

| Report Name | Electrospun Nanofiber Catalyst - Market |

| Forecasted market size in 2030 | US$ 587.3 million |

| CAGR | 6.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Argonide Nanomaterials, Mempro Ceramics, Hypercat Acp, Nanofiber Future, Inframat Advanced Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |