What is Motor Vehicle Brake Pads - Global Market?

Motor vehicle brake pads are a crucial component of the braking system in vehicles, playing a vital role in ensuring safety and performance. The global market for motor vehicle brake pads encompasses a wide range of products designed to meet the diverse needs of different vehicles, from passenger cars to commercial vehicles. These brake pads are engineered to provide optimal friction and durability, ensuring effective stopping power under various driving conditions. The market is driven by factors such as increasing vehicle production, advancements in brake pad materials, and growing awareness of vehicle safety. Manufacturers are continually innovating to develop brake pads that offer improved performance, reduced noise, and longer lifespan. The demand for brake pads is also influenced by stringent regulations regarding vehicle safety and emissions, prompting manufacturers to adopt eco-friendly materials and technologies. As the automotive industry evolves, the global market for motor vehicle brake pads is expected to witness steady growth, driven by the rising demand for vehicles and the need for enhanced safety features. This market is characterized by intense competition among key players, who are focusing on expanding their product portfolios and strengthening their distribution networks to gain a competitive edge.

Non-Asbestos Organic Brake Pads, Semi Metallic Brake Pads, Ceramic Brake Pads, Others in the Motor Vehicle Brake Pads - Global Market:

Non-asbestos organic (NAO) brake pads, semi-metallic brake pads, ceramic brake pads, and other types of brake pads each have unique characteristics that cater to different needs within the motor vehicle brake pads global market. Non-asbestos organic brake pads are made from a mixture of fibers, fillers, and binders, excluding asbestos, which was once a common material in brake pads due to its heat resistance. NAO brake pads are known for being quieter and producing less dust compared to other types. They are softer, which means they are gentler on brake rotors, but this also means they may wear out faster and may not perform as well under extreme conditions. These pads are often preferred for everyday driving in passenger vehicles where comfort and noise reduction are prioritized. Semi-metallic brake pads, on the other hand, contain a higher percentage of metal, such as steel, iron, or copper, mixed with organic materials. This composition makes them more durable and better suited for high-performance applications. They offer excellent heat dissipation and braking power, making them ideal for heavy-duty vehicles and performance cars. However, they can be noisier and produce more brake dust, which can be a drawback for some users. Ceramic brake pads are made from ceramic fibers, nonferrous filler materials, bonding agents, and small amounts of metal. They are known for their longevity, quiet operation, and low dust production. Ceramic pads provide consistent performance across a wide range of temperatures and driving conditions, making them a popular choice for many drivers. They are typically more expensive than other types of brake pads, but their benefits often justify the cost for those seeking a premium braking experience. Other types of brake pads in the market include low-metallic NAO pads, which offer a balance between the characteristics of NAO and semi-metallic pads, and specialty pads designed for specific applications, such as racing or off-road driving. Each type of brake pad has its own set of advantages and disadvantages, and the choice often depends on the specific requirements of the vehicle and the preferences of the driver. As technology advances, manufacturers continue to explore new materials and designs to enhance the performance and sustainability of brake pads, contributing to the dynamic nature of the global market.

Passenger Cars, Commercial Vehicle in the Motor Vehicle Brake Pads - Global Market:

Motor vehicle brake pads are essential for both passenger cars and commercial vehicles, serving as a critical component in ensuring safety and performance. In passenger cars, brake pads are designed to provide a smooth and quiet braking experience, prioritizing comfort and reliability. These vehicles typically use non-asbestos organic or ceramic brake pads, which offer a balance between performance and noise reduction. The focus is on providing a comfortable driving experience while maintaining effective stopping power. Passenger cars are often used for daily commuting and family transportation, where safety and comfort are paramount. As such, the choice of brake pads is influenced by factors such as noise levels, dust production, and overall braking performance. In commercial vehicles, which include trucks, buses, and other heavy-duty vehicles, the demands on brake pads are significantly higher. These vehicles often carry heavy loads and operate in challenging conditions, requiring brake pads that can withstand high temperatures and provide consistent performance. Semi-metallic brake pads are commonly used in commercial vehicles due to their durability and excellent heat dissipation properties. These pads are designed to handle the rigorous demands of commercial operations, ensuring safety and reliability even under extreme conditions. The choice of brake pads for commercial vehicles is driven by the need for durability, performance, and cost-effectiveness. In both passenger cars and commercial vehicles, the global market for motor vehicle brake pads is influenced by factors such as vehicle production, technological advancements, and regulatory requirements. Manufacturers are continually innovating to develop brake pads that meet the evolving needs of the automotive industry, focusing on improving performance, reducing noise, and enhancing sustainability. As the demand for vehicles continues to grow, the market for motor vehicle brake pads is expected to expand, driven by the need for enhanced safety features and improved braking performance.

Motor Vehicle Brake Pads - Global Market Outlook:

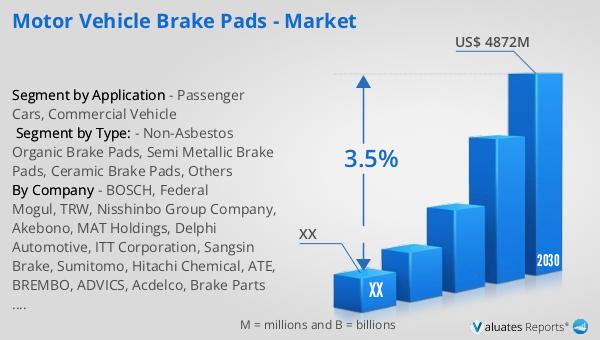

The global market for motor vehicle brake pads was valued at approximately $3,896.5 million in 2023. It is projected to grow to a revised size of $4,872 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. Currently, over 90% of the world's automobiles are concentrated in three major continents: Asia, Europe, and North America. Among these, Asia leads with 56% of the world's automobile production, followed by Europe at 20%, and North America at 16%. This distribution highlights the significant role these regions play in the global automotive industry and, consequently, in the demand for motor vehicle brake pads. The growth in the market is driven by factors such as increasing vehicle production, advancements in brake pad technology, and the rising demand for enhanced safety features. As the automotive industry continues to evolve, the market for motor vehicle brake pads is expected to witness steady growth, supported by the ongoing development of new materials and technologies that improve performance and sustainability. The competitive landscape is characterized by intense competition among key players, who are focusing on expanding their product portfolios and strengthening their distribution networks to gain a competitive edge.

| Report Metric | Details |

| Report Name | Motor Vehicle Brake Pads - Market |

| Forecasted market size in 2030 | US$ 4872 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BOSCH, Federal Mogul, TRW, Nisshinbo Group Company, Akebono, MAT Holdings, Delphi Automotive, ITT Corporation, Sangsin Brake, Sumitomo, Hitachi Chemical, ATE, BREMBO, ADVICS, Acdelco, Brake Parts Inc, ICER, Fras-le, EBC Brakes, ABS Friction, Shandong Gold Phoenix, Shangdong xinyi, SAL-FER, Hunan BoYun, Double Link |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |