What is Metal Extractant - Global Market?

Metal extractants are specialized chemicals used in the process of separating metals from their ores or other materials. These substances play a crucial role in the mining and metallurgical industries, where they are employed to efficiently and selectively extract valuable metals such as copper, nickel, cobalt, and rare earth elements from complex mixtures. The global market for metal extractants is driven by the increasing demand for these metals across various industries, including electronics, automotive, and renewable energy. As the world continues to transition towards cleaner energy sources and advanced technologies, the need for efficient metal extraction processes becomes more pronounced. Metal extractants are designed to target specific metals, ensuring high purity and yield, which is essential for producing high-quality end products. The market is characterized by continuous innovation, with companies investing in research and development to create more effective and environmentally friendly extractants. This dynamic landscape is shaped by regulatory standards, technological advancements, and the ever-evolving needs of industries reliant on metal resources. As such, the metal extractant market is poised for growth, driven by both economic and environmental factors.

Neutral Extractant, Acid Extractant, Alkaline Extractant, Others in the Metal Extractant - Global Market:

Neutral extractants, acid extractants, alkaline extractants, and other types of extractants each play a unique role in the global metal extractant market. Neutral extractants are typically used for their ability to selectively extract metals without altering the pH of the solution. They are particularly useful in processes where maintaining a stable pH is crucial, such as in the extraction of precious metals like gold and platinum. These extractants work by forming complexes with metal ions, allowing for their separation from other components in the mixture. Acid extractants, on the other hand, are employed in scenarios where the extraction process benefits from a lower pH environment. These extractants are effective in dissolving metal oxides and hydroxides, making them ideal for extracting metals like copper and zinc from their ores. Acid extractants often contain functional groups that can donate protons, facilitating the dissolution and subsequent extraction of metal ions. Alkaline extractants are used in processes that require a higher pH, such as the extraction of aluminum and certain rare earth elements. These extractants can form stable complexes with metal ions in alkaline conditions, enabling their separation from other materials. The choice of extractant depends on the specific metal being targeted, the composition of the ore, and the desired purity of the final product. Other types of extractants include chelating agents and ion exchange resins, which offer additional versatility in metal extraction processes. Chelating agents are organic compounds that can form multiple bonds with a single metal ion, enhancing the selectivity and efficiency of the extraction process. Ion exchange resins, meanwhile, are solid materials that can exchange ions with the surrounding solution, allowing for the selective removal of specific metal ions. These various types of extractants are integral to the global metal extractant market, providing the tools necessary for efficient and sustainable metal recovery.

Metallurgy, Mineral Processing, Explosives & Drilling, Water & Wastewater Treatment, Others in the Metal Extractant - Global Market:

Metal extractants find extensive usage across several key areas, including metallurgy, mineral processing, explosives and drilling, water and wastewater treatment, and other specialized applications. In metallurgy, metal extractants are crucial for refining and purifying metals to achieve the desired quality and specifications. They enable the separation of valuable metals from impurities, ensuring that the final product meets industry standards. This is particularly important in the production of high-purity metals used in electronics, aerospace, and other high-tech industries. In mineral processing, metal extractants are used to enhance the efficiency of ore beneficiation processes. By selectively extracting specific metals from complex ores, these extractants help maximize the yield and reduce the environmental impact of mining operations. This is essential for the sustainable development of mineral resources, as it minimizes waste and conserves energy. In the field of explosives and drilling, metal extractants are employed to recover metals from spent catalysts and other materials used in the production of explosives. This not only helps reduce waste but also provides a valuable source of metals that can be reused in various applications. In water and wastewater treatment, metal extractants play a vital role in removing heavy metals and other contaminants from industrial effluents and municipal wastewater. By selectively binding to metal ions, these extractants facilitate their removal from the water, ensuring compliance with environmental regulations and protecting public health. Other applications of metal extractants include their use in the recycling of electronic waste, where they help recover valuable metals from discarded devices. This is increasingly important as the demand for electronic products continues to rise, leading to a growing need for efficient recycling processes. Overall, the versatility and effectiveness of metal extractants make them indispensable in a wide range of industries, contributing to both economic growth and environmental sustainability.

Metal Extractant - Global Market Outlook:

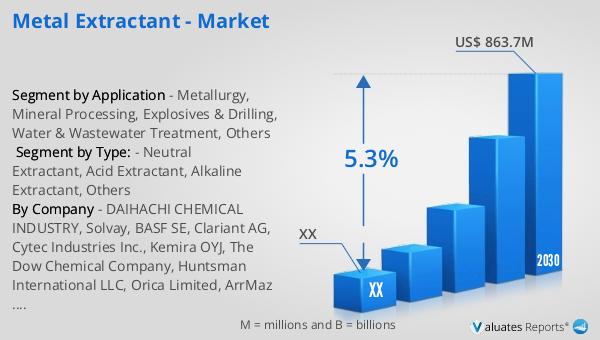

The global market for metal extractants was valued at approximately USD 600.7 million in 2023. This market is projected to grow significantly, reaching an estimated value of USD 863.7 million by the year 2030. This growth represents a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. This upward trend in the market can be attributed to several factors, including the increasing demand for metals across various industries, advancements in extraction technologies, and the growing emphasis on sustainable and environmentally friendly extraction processes. As industries such as electronics, automotive, and renewable energy continue to expand, the need for efficient and effective metal extraction solutions becomes more critical. Metal extractants offer a means to achieve high purity and yield in metal recovery, which is essential for producing high-quality end products. Additionally, the ongoing research and development efforts in the field of metal extractants are expected to lead to the creation of more innovative and efficient solutions, further driving market growth. The market's expansion is also supported by the increasing focus on recycling and resource conservation, as metal extractants play a key role in recovering valuable metals from waste materials. Overall, the metal extractant market is poised for significant growth, driven by both economic and environmental factors.

| Report Metric | Details |

| Report Name | Metal Extractant - Market |

| Forecasted market size in 2030 | US$ 863.7 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | DAIHACHI CHEMICAL INDUSTRY, Solvay, BASF SE, Clariant AG, Cytec Industries Inc., Kemira OYJ, The Dow Chemical Company, Huntsman International LLC, Orica Limited, ArrMaz Products, L.P., SNF Floerger, Kopper Chemical, DEYUAN FINE CHEMICALS, Mengrong Fine Mater, Sanmenxia Zhongda Chemical, Sannuo Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |