What is Medical Grade Laser Plastic Welding System - Global Market?

Medical Grade Laser Plastic Welding Systems are specialized tools used in the medical industry to join plastic components with precision and reliability. These systems utilize laser technology to create strong, clean, and precise welds without the need for additional materials like adhesives or solvents. The process involves directing a laser beam onto the plastic parts to be joined, which melts the material at the interface, allowing them to fuse together as they cool. This method is particularly advantageous in the medical field because it ensures high-quality, contamination-free joints that are essential for medical devices and equipment. The global market for these systems is expanding due to the increasing demand for advanced medical devices and the need for reliable and efficient manufacturing processes. As of 2023, the market was valued at approximately US$ 260 million and is projected to grow significantly in the coming years. This growth is driven by technological advancements, the rising prevalence of chronic diseases requiring sophisticated medical equipment, and the stringent regulatory standards that necessitate high-quality manufacturing processes. The adoption of laser plastic welding systems in the medical sector is expected to continue rising as manufacturers seek to improve product quality and production efficiency.

Fiber Laser Welding System, Diode Laser Welding System, Others in the Medical Grade Laser Plastic Welding System - Global Market:

Fiber Laser Welding Systems, Diode Laser Welding Systems, and other types of laser welding technologies play a crucial role in the Medical Grade Laser Plastic Welding System market. Fiber Laser Welding Systems are known for their high precision and efficiency. They use optical fibers to deliver the laser beam, which allows for a more focused and controlled welding process. This makes them ideal for applications requiring intricate and delicate welds, such as in the manufacturing of small medical devices and components. The ability to produce high-quality welds with minimal thermal distortion is a significant advantage, ensuring that the integrity of the medical devices is maintained. Diode Laser Welding Systems, on the other hand, are valued for their compact size and energy efficiency. They use semiconductor diodes to generate the laser beam, which can be easily modulated for different welding applications. This flexibility makes them suitable for a wide range of medical device manufacturing processes, from simple to complex assemblies. Diode lasers are particularly effective in applications where speed and precision are critical, such as in the production of disposable medical devices. Other laser welding technologies, including CO2 and Nd:YAG lasers, also contribute to the market by offering unique benefits. CO2 lasers are known for their ability to weld a variety of plastic materials, making them versatile tools in the medical manufacturing industry. Nd:YAG lasers, with their high peak power and pulse capabilities, are used in applications requiring deep penetration welding. Each of these technologies has its own set of advantages and is chosen based on the specific requirements of the medical device being manufactured. The global market for Medical Grade Laser Plastic Welding Systems is characterized by a diverse range of technologies, each catering to different aspects of medical device manufacturing. As the demand for advanced medical devices continues to grow, the adoption of these laser welding systems is expected to increase, driven by their ability to enhance product quality, reduce production costs, and meet stringent regulatory standards. Manufacturers are increasingly investing in these technologies to stay competitive and meet the evolving needs of the healthcare industry. The integration of laser welding systems into medical device manufacturing processes not only improves efficiency but also ensures the production of safe and reliable medical products.

Diagnostic Equipment, Laboratory Equipment, Others in the Medical Grade Laser Plastic Welding System - Global Market:

Medical Grade Laser Plastic Welding Systems are extensively used in various areas of the medical industry, including diagnostic equipment, laboratory equipment, and other medical applications. In the realm of diagnostic equipment, these systems are crucial for manufacturing devices that require precise and reliable joints. Diagnostic tools such as MRI machines, CT scanners, and ultrasound devices often contain numerous plastic components that need to be securely joined to ensure functionality and safety. Laser plastic welding provides the precision and strength needed for these applications, ensuring that the equipment operates effectively and safely. In laboratory equipment, the use of laser plastic welding systems is equally important. Laboratory devices such as pipettes, petri dishes, and centrifuges require high-quality welds to maintain sterility and functionality. The laser welding process ensures that these devices are free from contaminants and defects, which is essential for accurate and reliable laboratory results. The ability to produce clean and precise welds without the need for additional materials makes laser welding an ideal choice for laboratory equipment manufacturing. Beyond diagnostic and laboratory equipment, Medical Grade Laser Plastic Welding Systems are used in a variety of other medical applications. These include the production of surgical instruments, implantable devices, and drug delivery systems. The precision and reliability of laser welding are critical in these applications, where the quality of the weld can directly impact patient safety and treatment outcomes. For instance, in the production of implantable devices, laser welding ensures that the components are securely joined, reducing the risk of device failure and improving patient outcomes. Similarly, in drug delivery systems, precise welding is essential to ensure that the device functions correctly and delivers the medication as intended. The versatility and reliability of laser plastic welding systems make them indispensable in the medical industry, where the demand for high-quality, safe, and effective medical devices continues to grow. As the healthcare industry evolves and the need for advanced medical equipment increases, the use of Medical Grade Laser Plastic Welding Systems is expected to expand, driven by their ability to meet the stringent quality and safety standards required in medical device manufacturing.

Medical Grade Laser Plastic Welding System - Global Market Outlook:

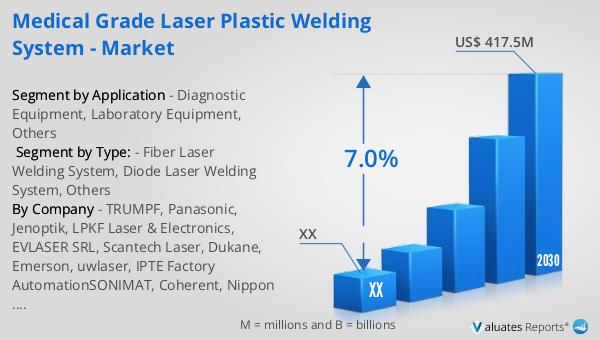

The global market outlook for Medical Grade Laser Plastic Welding Systems indicates a promising future, with significant growth anticipated over the coming years. In 2023, the market was valued at approximately US$ 260 million, reflecting the increasing demand for advanced medical manufacturing technologies. This demand is driven by the need for high-quality, reliable medical devices that meet stringent regulatory standards. As the healthcare industry continues to evolve, the adoption of laser plastic welding systems is expected to rise, fueled by their ability to enhance product quality and production efficiency. By 2030, the market is projected to reach a revised size of US$ 417.5 million, representing a compound annual growth rate (CAGR) of 7.0% during the forecast period from 2024 to 2030. This growth is indicative of the expanding applications of laser welding technology in the medical sector, as manufacturers seek to improve their production processes and meet the increasing demand for sophisticated medical devices. The integration of laser welding systems into medical device manufacturing not only improves efficiency but also ensures the production of safe and reliable medical products. As the market continues to grow, manufacturers are likely to invest more in these technologies to stay competitive and meet the evolving needs of the healthcare industry. The future of the Medical Grade Laser Plastic Welding System market looks bright, with continued advancements in technology and increasing demand for high-quality medical devices driving its growth.

| Report Metric | Details |

| Report Name | Medical Grade Laser Plastic Welding System - Market |

| Forecasted market size in 2030 | US$ 417.5 million |

| CAGR | 7.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | TRUMPF, Panasonic, Jenoptik, LPKF Laser & Electronics, EVLASER SRL, Scantech Laser, Dukane, Emerson, uwlaser, IPTE Factory AutomationSONIMAT, Coherent, Nippon Avionics, bielomatik, Leister Technologies, Control Micro Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |