What is Electronic Grade Laser Plastic Welding System - Global Market?

The Electronic Grade Laser Plastic Welding System is a specialized technology used in the precise joining of plastic components, particularly in industries where high precision and cleanliness are paramount. This system utilizes laser beams to weld plastic parts together, offering a non-contact method that ensures minimal contamination and high-quality welds. The global market for these systems is driven by the increasing demand for miniaturized and complex electronic components, which require precise and reliable joining techniques. As industries such as electronics, automotive, and medical devices continue to evolve, the need for advanced welding solutions like the Electronic Grade Laser Plastic Welding System grows. This technology is favored for its ability to produce strong, clean, and aesthetically pleasing welds without the need for additional materials or extensive post-processing. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the efficiency, speed, and versatility of these systems to meet the diverse needs of various applications. As a result, the Electronic Grade Laser Plastic Welding System is becoming an integral part of modern manufacturing processes, offering a competitive edge to companies that adopt this advanced technology.

Fiber Laser Welding System, Diode Laser Welding System, Others in the Electronic Grade Laser Plastic Welding System - Global Market:

The Fiber Laser Welding System is a key component of the Electronic Grade Laser Plastic Welding System market, known for its high precision and efficiency. Fiber lasers use optical fibers as the gain medium, which allows for a compact design and high power output. This makes them ideal for applications requiring fine detail and accuracy, such as in the electronics industry where components are becoming increasingly smaller and more complex. The ability of fiber lasers to produce consistent and high-quality welds makes them a preferred choice for manufacturers looking to enhance product reliability and performance. On the other hand, the Diode Laser Welding System is another significant segment within this market. Diode lasers are known for their energy efficiency and cost-effectiveness, making them suitable for high-volume production environments. They offer a good balance between performance and cost, which is particularly appealing to industries with tight budget constraints. Diode lasers are often used in applications where speed and efficiency are critical, such as in the automotive industry where large volumes of components need to be welded quickly and reliably. Apart from fiber and diode laser systems, there are other types of laser welding systems that cater to specific needs within the market. These include CO2 lasers, which are known for their ability to weld a wide range of materials, and Nd:YAG lasers, which offer high peak power and are suitable for applications requiring deep penetration welding. Each type of laser system has its own unique advantages and is chosen based on the specific requirements of the application. The diversity of laser welding systems available in the market ensures that manufacturers can select the most appropriate technology for their needs, whether it be for precision, speed, cost, or material compatibility. As the demand for electronic grade laser plastic welding systems continues to grow, the market is expected to see further advancements in laser technology, leading to even more efficient and versatile welding solutions.

Smartphone Components, Tablet Components, Others in the Electronic Grade Laser Plastic Welding System - Global Market:

The usage of Electronic Grade Laser Plastic Welding Systems in smartphone components is a testament to the technology's precision and reliability. Smartphones are composed of numerous small and intricate parts that require precise assembly to ensure functionality and durability. Laser plastic welding systems are ideal for this purpose as they provide clean and strong welds without damaging sensitive electronic components. This technology is used to join various parts of a smartphone, such as the housing, display modules, and internal components, ensuring a seamless and robust assembly. The ability to produce high-quality welds without the need for additional materials or adhesives is particularly advantageous in the smartphone industry, where space is limited and aesthetics are important. Similarly, in the production of tablet components, electronic grade laser plastic welding systems play a crucial role. Tablets, like smartphones, consist of multiple small and delicate parts that need to be assembled with precision. The use of laser welding technology ensures that these components are joined securely and without any risk of contamination, which is essential for maintaining the performance and longevity of the device. The non-contact nature of laser welding also minimizes the risk of damage to sensitive components, making it an ideal choice for the assembly of tablets. Beyond smartphones and tablets, electronic grade laser plastic welding systems are used in a variety of other applications where precision and cleanliness are critical. This includes the assembly of medical devices, automotive components, and consumer electronics, among others. In each of these areas, the ability to produce strong, clean, and reliable welds is essential for ensuring product quality and performance. The versatility of laser welding technology allows it to be adapted to a wide range of applications, making it a valuable tool for manufacturers across different industries. As the demand for high-quality and reliable electronic components continues to grow, the use of electronic grade laser plastic welding systems is expected to become even more widespread, driving further innovation and development in this field.

Electronic Grade Laser Plastic Welding System - Global Market Outlook:

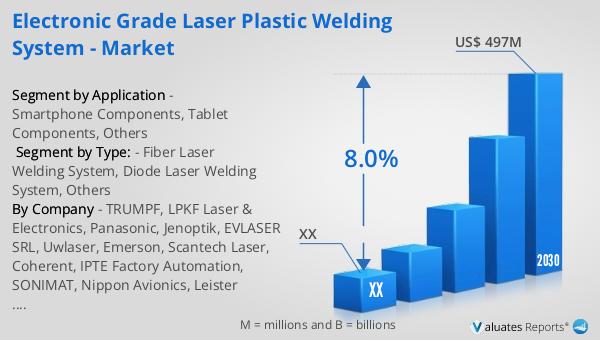

The global market for Electronic Grade Laser Plastic Welding Systems was valued at approximately $290 million in 2023. Looking ahead, this market is projected to expand significantly, reaching an estimated value of $497 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 8.0% over the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for advanced welding solutions in various industries, driven by the need for precision, efficiency, and reliability in the assembly of electronic components. The market's expansion is fueled by the continuous advancements in laser technology, which are enhancing the capabilities and applications of laser plastic welding systems. As industries such as electronics, automotive, and medical devices continue to evolve, the demand for high-quality and reliable welding solutions is expected to rise, further propelling the growth of the Electronic Grade Laser Plastic Welding System market. The projected growth of this market underscores the importance of laser welding technology in modern manufacturing processes and highlights the opportunities for innovation and development in this field. As companies strive to meet the increasing demands for precision and efficiency, the adoption of electronic grade laser plastic welding systems is likely to become more widespread, driving further growth and advancement in this market.

| Report Metric | Details |

| Report Name | Electronic Grade Laser Plastic Welding System - Market |

| Forecasted market size in 2030 | US$ 497 million |

| CAGR | 8.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | TRUMPF, LPKF Laser & Electronics, Panasonic, Jenoptik, EVLASER SRL, Uwlaser, Emerson, Scantech Laser, Coherent, IPTE Factory Automation, SONIMAT, Nippon Avionics, Leister Technologies, Control Micro Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |