What is Automotive Grade Laser Plastic Welding System - Global Market?

The Automotive Grade Laser Plastic Welding System is a specialized technology used in the automotive industry to join plastic components with precision and strength. This system employs laser beams to melt and fuse plastic parts together, ensuring a seamless and durable bond. The global market for this technology is expanding due to the increasing demand for lightweight and fuel-efficient vehicles. As manufacturers strive to reduce vehicle weight, the use of plastic components has surged, necessitating advanced welding techniques like laser plastic welding. This system offers numerous advantages, including high precision, minimal thermal distortion, and the ability to weld complex shapes. It is particularly beneficial in producing intricate automotive parts where traditional welding methods may fall short. The market's growth is driven by technological advancements, increased automotive production, and the rising adoption of electric vehicles, which require sophisticated manufacturing processes. As the automotive industry continues to evolve, the demand for efficient and reliable welding systems like the Automotive Grade Laser Plastic Welding System is expected to rise, making it a crucial component in modern vehicle manufacturing.

Transmission Laser Welding System, Absorption Laser Welding System, Others in the Automotive Grade Laser Plastic Welding System - Global Market:

The Transmission Laser Welding System is a key segment within the Automotive Grade Laser Plastic Welding System market. This system utilizes laser beams to penetrate through a transparent plastic layer and weld it to an underlying absorbent layer. This method is highly efficient for joining dissimilar materials and is widely used in the automotive industry for its precision and speed. It allows for the creation of strong, hermetic seals, which are essential in automotive applications where durability and reliability are paramount. The Transmission Laser Welding System is particularly advantageous in producing components that require high aesthetic quality and minimal post-processing. On the other hand, the Absorption Laser Welding System operates by directing laser energy onto the surface of the plastic, which absorbs the energy and melts to form a bond. This system is ideal for welding opaque plastics and is commonly used in applications where the welded joint is not visible. It offers flexibility in terms of material compatibility and is often employed in the production of under-the-hood components and other non-visible parts. Additionally, there are other laser welding systems that cater to specific needs within the automotive industry. These systems may include hybrid laser welding, which combines laser welding with other welding techniques to enhance performance and efficiency. Each of these systems plays a vital role in the automotive manufacturing process, offering unique benefits that cater to different requirements. As the demand for lightweight and complex automotive components continues to grow, the adoption of these advanced laser welding systems is expected to increase, driving innovation and efficiency in the industry.

Interior Components, Electrical Components, Fuel System Components, Others in the Automotive Grade Laser Plastic Welding System - Global Market:

The usage of Automotive Grade Laser Plastic Welding Systems spans various areas within the automotive industry, each with its unique requirements and benefits. In the realm of interior components, these systems are employed to join parts such as dashboards, door panels, and center consoles. The precision and cleanliness of laser welding make it ideal for producing aesthetically pleasing and structurally sound interior parts. This technology allows for the seamless integration of different materials, enhancing the overall design and functionality of the vehicle's interior. In the case of electrical components, laser plastic welding is crucial for ensuring the integrity and reliability of parts such as connectors, sensors, and control units. The ability to create hermetic seals is particularly important in protecting sensitive electronic components from moisture and contaminants, thereby enhancing their performance and longevity. For fuel system components, laser welding provides a robust solution for joining parts like fuel tanks, pumps, and filters. The strength and precision of the welds ensure that these components can withstand the harsh conditions they are exposed to, such as pressure and temperature fluctuations. This is critical in maintaining the safety and efficiency of the vehicle's fuel system. Beyond these specific areas, laser plastic welding systems are also used in other applications, such as the production of lighting components, air intake systems, and fluid reservoirs. The versatility and adaptability of laser welding technology make it an invaluable tool in the automotive manufacturing process, enabling the production of high-quality, reliable components that meet the industry's stringent standards.

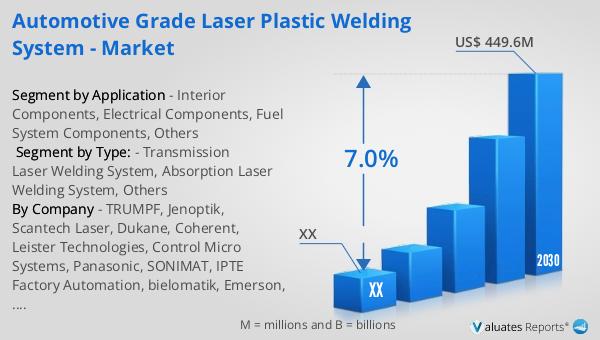

Automotive Grade Laser Plastic Welding System - Global Market Outlook:

In 2023, the global market for Automotive Grade Laser Plastic Welding Systems was valued at approximately US$ 280 million. This market is projected to grow significantly, reaching an estimated size of US$ 449.6 million by 2030. This growth represents a compound annual growth rate (CAGR) of 7.0% during the forecast period from 2024 to 2030. The increasing demand for lightweight and fuel-efficient vehicles is a major driver of this market expansion. As automotive manufacturers continue to innovate and develop new models, the need for advanced welding technologies that can efficiently join plastic components is becoming more pronounced. The adoption of electric vehicles, which require sophisticated manufacturing processes, is also contributing to the market's growth. Additionally, technological advancements in laser welding systems are enhancing their capabilities and expanding their applications within the automotive industry. These factors, combined with the rising production of vehicles globally, are expected to fuel the demand for Automotive Grade Laser Plastic Welding Systems in the coming years. As the market continues to evolve, manufacturers and suppliers will need to adapt to changing demands and leverage new technologies to maintain their competitive edge.

| Report Metric | Details |

| Report Name | Automotive Grade Laser Plastic Welding System - Market |

| Forecasted market size in 2030 | US$ 449.6 million |

| CAGR | 7.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | TRUMPF, Jenoptik, Scantech Laser, Dukane, Coherent, Leister Technologies, Control Micro Systems, Panasonic, SONIMAT, IPTE Factory Automation, bielomatik, Emerson, Nippon Avionics, uwlaser, EVLASER SRL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |