What is Medical 3D Printing Plastic - Global Market?

Medical 3D printing plastic is a specialized segment within the broader 3D printing industry, focusing on the development and application of plastic materials for medical purposes. This market is driven by the increasing demand for customized medical solutions, which 3D printing can provide with precision and efficiency. The global market for medical 3D printing plastics encompasses a variety of materials, each offering unique properties suitable for different medical applications. These plastics are used to create a wide range of medical devices and components, from surgical instruments to prosthetics and implants. The versatility of 3D printing allows for rapid prototyping and production, which is particularly beneficial in the medical field where time and customization are critical. As the technology advances, the range of materials and their applications continue to expand, offering new possibilities for patient-specific treatments and innovations in healthcare. The market is characterized by ongoing research and development, aiming to improve the biocompatibility, strength, and functionality of these materials to meet the stringent requirements of medical applications. This dynamic market is poised for growth as healthcare providers increasingly adopt 3D printing technologies to enhance patient care and operational efficiency.

ABS, PEEK, PETG, Others in the Medical 3D Printing Plastic - Global Market:

Acrylonitrile Butadiene Styrene (ABS) is one of the most commonly used plastics in 3D printing, known for its strength, flexibility, and resistance to high temperatures. In the medical 3D printing plastic market, ABS is valued for its durability and ease of use, making it suitable for creating robust medical devices and prototypes. Its ability to withstand sterilization processes makes it a viable option for producing surgical instruments and other reusable medical tools. However, ABS is not typically used for implants due to its lack of biocompatibility. Polyether Ether Ketone (PEEK) is another high-performance plastic that is gaining traction in the medical 3D printing market. Known for its exceptional mechanical properties and biocompatibility, PEEK is often used in the production of implants, such as spinal cages and dental implants. Its resistance to wear and chemical degradation makes it ideal for long-term implantation. PEEK's ability to mimic the mechanical properties of bone further enhances its suitability for orthopedic applications. Polyethylene Terephthalate Glycol (PETG) is a glycol-modified version of PET, offering enhanced durability and clarity. In the medical field, PETG is used for creating clear, strong, and sterilizable components, such as medical device housings and protective equipment. Its ease of printing and post-processing makes it a popular choice for rapid prototyping and production. Other materials in the medical 3D printing plastic market include polylactic acid (PLA), which is biodegradable and used for temporary implants and surgical guides, and thermoplastic polyurethane (TPU), known for its flexibility and used in applications requiring elasticity, such as prosthetics and orthotics. Each of these materials offers distinct advantages and limitations, influencing their suitability for specific medical applications. The choice of material depends on factors such as the required mechanical properties, biocompatibility, and the intended use of the final product. As the medical 3D printing market continues to evolve, the development of new materials and the improvement of existing ones will play a crucial role in expanding the range of applications and enhancing the performance of 3D-printed medical devices.

Personal Protective Wearables, Dental and Bone Implants, Catheters, Prosthetics, Others in the Medical 3D Printing Plastic - Global Market:

Medical 3D printing plastics are revolutionizing the production of personal protective wearables, dental and bone implants, catheters, prosthetics, and other medical devices. In the realm of personal protective wearables, 3D printing allows for the rapid production of customized face shields, masks, and other protective gear. These items can be tailored to fit individual users, providing enhanced comfort and protection. The ability to quickly produce these items on-demand is particularly valuable in situations where traditional supply chains are disrupted, such as during a pandemic. In the field of dental and bone implants, 3D printing plastics offer the ability to create patient-specific implants that match the exact dimensions and contours of a patient's anatomy. This customization improves the fit and function of the implants, leading to better patient outcomes. Materials like PEEK are particularly suited for these applications due to their biocompatibility and mechanical properties. For catheters, 3D printing allows for the production of complex geometries that are difficult to achieve with traditional manufacturing methods. This capability enables the creation of catheters with improved functionality and patient comfort. In the area of prosthetics, 3D printing plastics provide a cost-effective and efficient way to produce custom prosthetic limbs and devices. The ability to tailor these devices to the specific needs and measurements of the user enhances their comfort and usability. Other applications of medical 3D printing plastics include the production of surgical guides, anatomical models for surgical planning, and drug delivery devices. The versatility and adaptability of 3D printing technology make it an invaluable tool in the medical field, offering new possibilities for personalized medicine and improved patient care. As the technology continues to advance, the range of applications for medical 3D printing plastics is expected to grow, further transforming the landscape of healthcare.

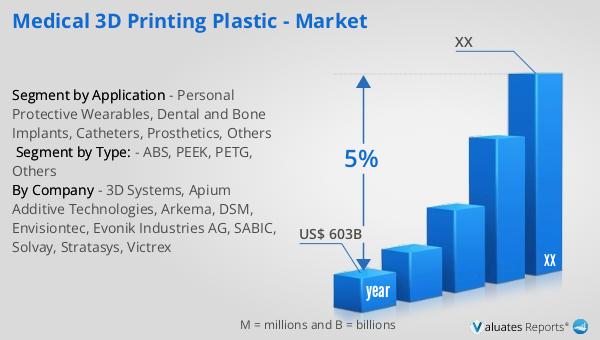

Medical 3D Printing Plastic - Global Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023. This substantial market size reflects the growing demand for advanced medical technologies and innovations that enhance patient care and treatment outcomes. Over the next six years, the market is anticipated to expand at a compound annual growth rate (CAGR) of 5%. This growth trajectory underscores the increasing adoption of cutting-edge medical devices across various healthcare settings, driven by factors such as an aging population, rising prevalence of chronic diseases, and technological advancements. The steady growth rate also highlights the ongoing investment in research and development, as well as the continuous efforts to improve the accessibility and affordability of medical devices worldwide. As healthcare systems strive to meet the evolving needs of patients, the medical device market is poised to play a crucial role in shaping the future of healthcare delivery. The expansion of this market is expected to bring about significant advancements in medical technology, ultimately leading to improved patient outcomes and enhanced quality of life.

| Report Metric | Details |

| Report Name | Medical 3D Printing Plastic - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3D Systems, Apium Additive Technologies, Arkema, DSM, Envisiontec, Evonik Industries AG, SABIC, Solvay, Stratasys, Victrex |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |