What is Jewellery Laser Welding Machine - Global Market?

Jewellery laser welding machines are specialized tools used in the jewelry industry to join metal pieces with precision and minimal heat impact. These machines utilize a focused laser beam to weld metals, allowing for intricate designs and repairs without damaging delicate components. The global market for these machines is expanding as jewelers seek more efficient and precise methods for crafting and repairing jewelry. The technology offers significant advantages over traditional welding methods, such as reduced risk of metal distortion and the ability to work with a wide range of metals, including gold, silver, and platinum. As the demand for custom and high-quality jewelry increases, the adoption of laser welding machines is expected to grow. These machines are not only used by large manufacturers but also by small jewelry shops and individual artisans who value the precision and efficiency they offer. The market is characterized by a variety of machine types, catering to different needs and scales of operation, from fully automated systems to semi-automatic models that offer a balance between control and efficiency.

Full Automatic Type, Semi Automatic Type in the Jewellery Laser Welding Machine - Global Market:

In the global market for jewellery laser welding machines, there are primarily two types of machines that cater to different needs and preferences: full automatic and semi-automatic types. Full automatic laser welding machines are designed for high-volume production environments where speed and consistency are paramount. These machines are equipped with advanced software and sensors that allow them to perform welding tasks with minimal human intervention. They are ideal for large manufacturers who need to produce a high volume of jewelry pieces with consistent quality. The automation ensures that each weld is performed with precision, reducing the likelihood of errors and increasing overall efficiency. These machines often come with features such as programmable settings, automatic material feeding, and real-time monitoring, which further enhance their productivity and reliability. On the other hand, semi-automatic laser welding machines offer a balance between automation and manual control. These machines are preferred by smaller manufacturers and artisans who require a certain level of flexibility and control over the welding process. While they still incorporate some automated features, such as laser power adjustment and basic programming capabilities, they allow the operator to manually guide the welding process. This is particularly useful for custom or intricate designs where human expertise and judgment are crucial. Semi-automatic machines are also more affordable than their fully automatic counterparts, making them accessible to a wider range of users. Both types of machines have their own set of advantages and are chosen based on the specific needs of the user. Full automatic machines are ideal for large-scale production, where speed and consistency are critical, while semi-automatic machines offer the flexibility and control needed for custom and small-batch production. As the global market for jewellery laser welding machines continues to grow, manufacturers are constantly innovating to improve the capabilities and features of both types of machines. This includes advancements in laser technology, user interfaces, and integration with other manufacturing processes. The choice between full automatic and semi-automatic machines ultimately depends on the specific requirements of the user, including the scale of production, budget, and the level of precision needed. As technology continues to evolve, we can expect to see further improvements in both types of machines, making them even more efficient and versatile for the jewelry industry.

Jewelry Maker, Jewelry Shop, Others in the Jewellery Laser Welding Machine - Global Market:

Jewellery laser welding machines are used in various areas within the jewelry industry, including jewelry makers, jewelry shops, and other related sectors. For jewelry makers, these machines are invaluable tools that enable them to create intricate designs and perform precise repairs. The ability to weld metals with minimal heat impact allows jewelry makers to work with delicate components without risking damage. This is particularly important for custom jewelry pieces, where precision and attention to detail are crucial. Jewelry makers can use laser welding machines to join small metal parts, repair broken pieces, and even add embellishments to existing designs. The versatility of these machines makes them an essential part of the jewelry-making process, allowing artisans to push the boundaries of creativity and craftsmanship. In jewelry shops, laser welding machines are used primarily for repair and maintenance purposes. These machines enable jewelers to offer quick and efficient repair services to their customers, enhancing customer satisfaction and loyalty. Whether it's fixing a broken clasp, resizing a ring, or repairing a damaged chain, laser welding machines provide a reliable solution that ensures high-quality results. The precision of laser welding also means that repairs can be done without leaving visible marks or altering the appearance of the jewelry, which is a significant advantage for maintaining the aesthetic value of the pieces. Additionally, the use of laser welding machines in jewelry shops can reduce the time and cost associated with outsourcing repairs, allowing shops to offer competitive pricing and faster turnaround times. Beyond jewelry makers and shops, laser welding machines are also used in other areas of the jewelry industry, such as manufacturing and quality control. In manufacturing, these machines are used to assemble jewelry pieces with high precision and consistency, ensuring that each piece meets the desired specifications. This is particularly important for large-scale production, where maintaining uniformity and quality across thousands of pieces is essential. In quality control, laser welding machines can be used to inspect and repair any defects or inconsistencies in the finished products, ensuring that only the highest quality pieces reach the market. The use of laser welding machines in these areas highlights their versatility and importance in the jewelry industry. As the demand for high-quality and custom jewelry continues to grow, the adoption of laser welding machines is expected to increase, driving further innovation and development in this field.

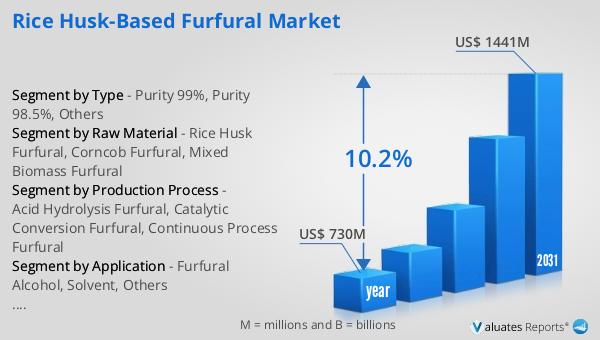

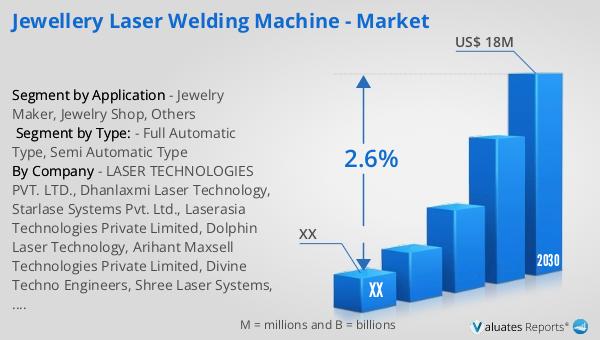

Jewellery Laser Welding Machine - Global Market Outlook:

The global market for jewellery laser welding machines was valued at approximately $16 million in 2023. It is projected to grow to a revised size of $18 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.6% during the forecast period from 2024 to 2030. This growth indicates a steady increase in demand for these machines, driven by the need for precision and efficiency in the jewelry industry. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The increasing adoption of laser welding technology in North America can be attributed to the region's strong focus on innovation and quality in jewelry manufacturing. As more jewelers and manufacturers recognize the benefits of laser welding, such as reduced metal distortion and the ability to work with a wide range of metals, the market is likely to expand further. The projected growth in the global market for jewellery laser welding machines underscores the importance of this technology in the jewelry industry and highlights the opportunities for manufacturers and suppliers to capitalize on this trend.

| Report Metric | Details |

| Report Name | Jewellery Laser Welding Machine - Market |

| Forecasted market size in 2030 | US$ 18 million |

| CAGR | 2.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | LASER TECHNOLOGIES PVT. LTD., Dhanlaxmi Laser Technology, Starlase Systems Pvt. Ltd., Laserasia Technologies Private Limited, Dolphin Laser Technology, Arihant Maxsell Technologies Private Limited, Divine Techno Engineers, Shree Laser Systems, Suresh Indu Lasers Pvt Ltd, Miracle Machinery, ALPHA LASER GmbH, Futurebit Laser Technology, Trilok Lasers Private Limited, Evotech Pacific |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |