What is Handheld Dot Peen Marking Machine - Global Market?

Handheld Dot Peen Marking Machines are innovative tools used globally for engraving permanent marks on various surfaces. These machines utilize a stylus that rapidly strikes the surface, creating a series of dots that form characters, logos, or other designs. The handheld nature of these devices makes them highly versatile and portable, allowing for easy use in different environments, from industrial settings to small workshops. They are particularly valued for their ability to mark hard materials like metal and steel, as well as plastics, with precision and durability. The global market for these machines is expanding as industries increasingly demand reliable and efficient marking solutions. This growth is driven by the need for traceability, product identification, and compliance with industry standards. As technology advances, these machines are becoming more user-friendly and capable of handling complex marking tasks, further boosting their adoption across various sectors. The market's expansion is also supported by the development of more affordable and efficient models, making them accessible to a broader range of businesses. Overall, the Handheld Dot Peen Marking Machine market is poised for significant growth as it continues to meet the evolving needs of industries worldwide.

Wired, Wireless in the Handheld Dot Peen Marking Machine - Global Market:

In the global market for Handheld Dot Peen Marking Machines, the distinction between wired and wireless models plays a crucial role in meeting diverse industrial needs. Wired handheld dot peen marking machines are typically favored in environments where a stable and continuous power supply is essential. These machines are often used in fixed locations where mobility is not a primary concern, such as assembly lines or workshops. The wired connection ensures consistent power delivery, which can be critical for high-volume marking tasks that require precision and speed. On the other hand, wireless handheld dot peen marking machines offer unparalleled flexibility and mobility. They are ideal for fieldwork or situations where the marking needs to be done on large or immovable objects. The absence of cables allows operators to maneuver the device freely, making it easier to mark hard-to-reach areas. Wireless models are equipped with rechargeable batteries, which provide sufficient power for extended use, although they may require periodic recharging. The choice between wired and wireless models often depends on the specific requirements of the task at hand, including the environment, the nature of the materials being marked, and the volume of work. Both types of machines are designed to deliver high-quality, durable markings that withstand harsh conditions, ensuring traceability and compliance with industry standards. As technology continues to evolve, the performance gap between wired and wireless models is narrowing, with advancements in battery technology and wireless connectivity enhancing the capabilities of wireless machines. This evolution is contributing to the growing popularity of wireless models in the global market. However, wired machines remain a staple in many industrial settings due to their reliability and consistent performance. The global market for Handheld Dot Peen Marking Machines is thus characterized by a balance between these two types of machines, each offering unique advantages that cater to different industrial needs. As industries continue to prioritize efficiency and flexibility, the demand for both wired and wireless handheld dot peen marking machines is expected to grow, driven by their ability to provide reliable and precise marking solutions across various applications.

Steel, Metal, Hard Plastic Materials, Others in the Handheld Dot Peen Marking Machine - Global Market:

Handheld Dot Peen Marking Machines are extensively used in marking steel, metal, hard plastic materials, and other surfaces, making them indispensable tools in various industries. In the steel industry, these machines are used to engrave serial numbers, barcodes, and other identifiers on steel components. The durability of the markings ensures that they remain legible even in harsh environments, such as those involving high temperatures or corrosive substances. This is crucial for traceability and quality control, as it allows manufacturers to track products throughout the supply chain. In the metal industry, handheld dot peen marking machines are used to mark a wide range of metal products, from automotive parts to aerospace components. The precision and depth of the markings make them ideal for applications where readability and permanence are essential. These machines can handle various metal types, including aluminum, brass, and stainless steel, providing versatility in marking different products. For hard plastic materials, handheld dot peen marking machines offer a reliable solution for creating permanent marks without damaging the material. This is particularly important in industries such as electronics and consumer goods, where product identification and branding are critical. The machines can produce clear and precise markings on plastic surfaces, ensuring that information such as logos, serial numbers, and manufacturing dates are easily readable. Beyond steel, metal, and plastic, handheld dot peen marking machines are also used in other applications, such as marking wood, glass, and ceramics. Their versatility and adaptability make them suitable for a wide range of materials, providing industries with a flexible and efficient marking solution. The global market for these machines is driven by their ability to meet the diverse marking needs of various industries, ensuring product traceability, compliance, and quality assurance. As industries continue to evolve and demand more sophisticated marking solutions, the usage of handheld dot peen marking machines is expected to expand, further solidifying their position in the global market.

Handheld Dot Peen Marking Machine - Global Market Outlook:

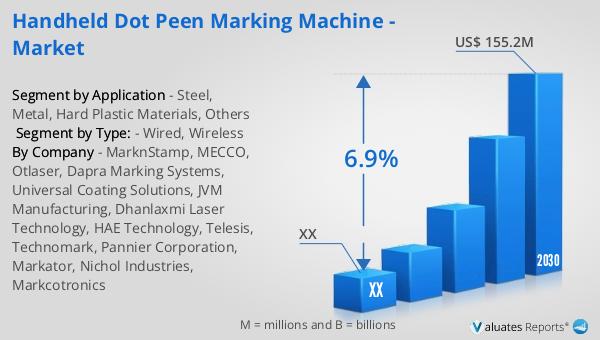

The global market for Handheld Dot Peen Marking Machines was valued at approximately $98 million in 2023. It is projected to grow to a revised size of $155.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.9% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and reliable marking solutions across various industries. In North America, the market for these machines was valued at a certain amount in 2023, with expectations to reach a higher value by 2030, maintaining a steady CAGR throughout the forecast period. This regional growth underscores the importance of these machines in supporting industrial activities that require precise and durable markings. The market's expansion is driven by technological advancements that enhance the capabilities of these machines, making them more accessible and efficient for a wide range of applications. As industries continue to prioritize traceability and compliance, the demand for handheld dot peen marking machines is expected to rise, contributing to the overall growth of the global market. The increasing adoption of these machines in various sectors highlights their significance in meeting the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Handheld Dot Peen Marking Machine - Market |

| Forecasted market size in 2030 | US$ 155.2 million |

| CAGR | 6.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | MarknStamp, MECCO, Otlaser, Dapra Marking Systems, Universal Coating Solutions, JVM Manufacturing, Dhanlaxmi Laser Technology, HAE Technology, Telesis, Technomark, Pannier Corporation, Markator, Nichol Industries, Markcotronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |