What is High Precision Resin 3D Printer - Global Market?

High Precision Resin 3D printers are specialized devices that utilize advanced technology to create highly detailed and accurate three-dimensional objects from resin materials. These printers are particularly known for their ability to produce intricate designs with smooth finishes, making them ideal for industries that require precision and fine detail. The global market for these printers is expanding as more industries recognize the benefits of high precision 3D printing. This growth is driven by the increasing demand for customized products, rapid prototyping, and the ability to produce complex geometries that traditional manufacturing methods cannot achieve. High Precision Resin 3D printers are used in various sectors, including consumer electronics, automotive, medical, dental, and aerospace, where precision and detail are paramount. The market is characterized by continuous technological advancements, leading to improved printer capabilities, faster production times, and reduced costs. As a result, businesses are increasingly adopting these printers to enhance their manufacturing processes and product offerings. The global market for High Precision Resin 3D printers is poised for significant growth as industries continue to explore and leverage the capabilities of this innovative technology.

SLA Printing, DLP Printing, LCD Printing, Others in the High Precision Resin 3D Printer - Global Market:

Stereolithography (SLA) printing is one of the most established methods in the realm of high precision resin 3D printing. It works by using a laser to cure liquid resin into hardened plastic in a layer-by-layer fashion. This technique is renowned for its ability to produce parts with exceptional detail and smooth surface finishes, making it a popular choice for applications that require high accuracy and fine details, such as in the dental and jewelry industries. SLA printers are often used for creating prototypes, intricate models, and even functional parts. Digital Light Processing (DLP) printing, on the other hand, uses a digital projector screen to flash a single image of each layer across the entire platform, curing the resin simultaneously. This method is generally faster than SLA because it cures an entire layer at once rather than tracing it with a laser. DLP is favored for its speed and efficiency, especially in applications where time is a critical factor. It is commonly used in the production of dental aligners and other medical devices where precision and speed are essential. LCD printing, similar to DLP, uses an LCD screen to project UV light to cure the resin. The main difference lies in the light source; LCD printers use an array of LEDs to provide the necessary illumination. This method is often more cost-effective than DLP and SLA, making it accessible for smaller businesses or hobbyists who require high precision without the high costs. LCD printing is gaining popularity in the consumer electronics sector for creating detailed components and prototypes. Other methods in high precision resin 3D printing include MultiJet and PolyJet technologies, which use multiple nozzles to jet layers of resin that are then cured by UV light. These methods are known for their ability to produce multi-material and multi-color parts, offering versatility in design and application. They are particularly useful in industries that require complex assemblies and detailed color patterns, such as in the production of consumer goods and automotive components. Each of these printing technologies offers unique advantages and is chosen based on the specific requirements of the application, such as the desired level of detail, production speed, and material properties. As the global market for high precision resin 3D printers continues to grow, these technologies are expected to evolve, offering even greater capabilities and efficiencies.

Consumer Electronics, Automotive, Medical, Dental, Aerospace, Others in the High Precision Resin 3D Printer - Global Market:

High Precision Resin 3D printers are increasingly being utilized across a variety of industries due to their ability to produce highly detailed and accurate parts. In the consumer electronics sector, these printers are used to create intricate components and prototypes that require precision and fine detail. This includes parts for smartphones, wearables, and other electronic devices where the demand for miniaturization and complex geometries is high. In the automotive industry, high precision resin 3D printers are employed to produce prototypes and functional parts that require high accuracy and durability. This includes components for engines, interiors, and custom parts that enhance vehicle performance and aesthetics. The ability to quickly produce and test prototypes allows automotive manufacturers to accelerate their design and development processes, reducing time to market. In the medical field, these printers are used to create custom implants, prosthetics, and surgical guides that require precise measurements and biocompatibility. The ability to produce patient-specific devices enhances the effectiveness of medical treatments and improves patient outcomes. Similarly, in the dental industry, high precision resin 3D printers are used to produce crowns, bridges, and aligners with high accuracy and detail, improving the fit and comfort for patients. The aerospace industry also benefits from high precision resin 3D printing, as it allows for the production of lightweight and complex components that are essential for aircraft and spacecraft. The ability to produce parts with intricate geometries and reduced weight contributes to improved fuel efficiency and performance. Other industries, such as jewelry and fashion, also leverage high precision resin 3D printers to create detailed and customized designs that are not possible with traditional manufacturing methods. The versatility and precision offered by these printers make them an invaluable tool for industries that require high-quality and customized products.

High Precision Resin 3D Printer - Global Market Outlook:

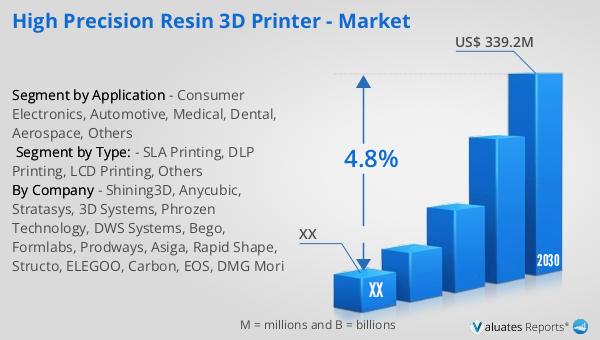

The global market for High Precision Resin 3D Printers was valued at approximately $204 million in 2023. Looking ahead, this market is projected to grow significantly, reaching an estimated value of $339.2 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. This upward trend is indicative of the increasing adoption of high precision resin 3D printing technology across various industries. The demand for these printers is driven by their ability to produce highly detailed and accurate parts, which are essential in sectors such as consumer electronics, automotive, medical, dental, and aerospace. As industries continue to seek innovative solutions to enhance their manufacturing processes and product offerings, the market for high precision resin 3D printers is expected to expand further. The continuous advancements in 3D printing technology, coupled with the growing need for customized and complex products, are key factors contributing to the market's growth. As a result, businesses are increasingly investing in high precision resin 3D printers to stay competitive and meet the evolving demands of their customers. This market outlook highlights the promising future of high precision resin 3D printing technology and its potential to revolutionize various industries.

| Report Metric | Details |

| Report Name | High Precision Resin 3D Printer - Market |

| Forecasted market size in 2030 | US$ 339.2 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Shining3D, Anycubic, Stratasys, 3D Systems, Phrozen Technology, DWS Systems, Bego, Formlabs, Prodways, Asiga, Rapid Shape, Structo, ELEGOO, Carbon, EOS, DMG Mori |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |