What is Global Live Pallet Racking Market?

The Global Live Pallet Racking Market is a specialized segment within the broader storage and logistics industry, focusing on systems that enhance the efficiency of storing and retrieving palletized goods. These racking systems are designed to optimize space utilization and improve the flow of goods in warehouses and distribution centers. Live pallet racking systems, often referred to as dynamic storage systems, use gravity or mechanical systems to move pallets from the loading end to the picking end. This setup allows for a more streamlined and efficient handling process, reducing the time and labor required for inventory management. The market for these systems is driven by the increasing demand for efficient storage solutions in various industries, including retail, manufacturing, and logistics. As businesses strive to improve their supply chain operations, the adoption of live pallet racking systems is expected to grow, offering benefits such as reduced storage costs, improved inventory turnover, and enhanced operational efficiency. The market is characterized by a range of products, including FIFO (First In, First Out) and LIFO (Last In, First Out) systems, each catering to different storage needs and operational requirements.

FIFO, LIFO in the Global Live Pallet Racking Market:

FIFO (First In, First Out) and LIFO (Last In, First Out) are two fundamental inventory management methods that play a crucial role in the Global Live Pallet Racking Market. These systems are designed to optimize the flow of goods in storage facilities, ensuring that inventory is managed efficiently and effectively. FIFO is a method where the oldest inventory is used or sold first. This approach is particularly beneficial for products with expiration dates, such as perishable goods, pharmaceuticals, and food items. In a live pallet racking system, FIFO is achieved by loading new pallets at one end of the rack and retrieving them from the other end. This ensures that the oldest stock is always accessed first, reducing the risk of spoilage or obsolescence. The FIFO system is widely adopted in industries where product freshness is critical, and it helps in maintaining a consistent turnover of inventory, thereby optimizing storage space and reducing waste. On the other hand, LIFO is a method where the most recently added inventory is used or sold first. This approach is often used in industries where products do not have a shelf life, such as construction materials or raw goods. In a live pallet racking system, LIFO is implemented by loading and retrieving pallets from the same end of the rack. This method is advantageous in scenarios where storage space is limited, and there is a need to quickly access the most recently stored items. LIFO can also be beneficial in times of rising prices, as it allows businesses to match current sales with the most recent, and often higher, inventory costs, potentially reducing taxable income. However, it is important to note that LIFO is not permitted under International Financial Reporting Standards (IFRS), which can limit its applicability for companies operating in multiple countries. Both FIFO and LIFO systems have their unique advantages and are chosen based on the specific needs of a business. In the context of the Global Live Pallet Racking Market, these systems offer flexibility and efficiency, enabling businesses to tailor their storage solutions to their operational requirements. The choice between FIFO and LIFO depends on various factors, including the nature of the products being stored, the available storage space, and the financial and regulatory considerations of the business. As the demand for efficient storage solutions continues to grow, the adoption of FIFO and LIFO systems in live pallet racking is expected to increase, providing businesses with the tools they need to optimize their inventory management processes.

Warehouses, Stores, Production Facilities, Workshops, Others in the Global Live Pallet Racking Market:

The Global Live Pallet Racking Market finds extensive usage across various sectors, including warehouses, stores, production facilities, workshops, and other areas where efficient storage solutions are critical. In warehouses, live pallet racking systems are employed to maximize storage density and improve the speed of inventory turnover. These systems allow for the efficient organization of goods, making it easier to manage large volumes of inventory. By utilizing gravity or mechanical systems, live pallet racking enables quick and easy access to stored items, reducing the time and labor required for picking and replenishment. This is particularly beneficial in high-volume distribution centers where speed and efficiency are paramount. In retail stores, live pallet racking systems are used to optimize the storage of products, ensuring that shelves are always stocked with the latest inventory. This is especially important in environments where product availability directly impacts sales and customer satisfaction. By implementing live pallet racking, stores can maintain a seamless flow of goods from the backroom to the sales floor, minimizing stockouts and enhancing the overall shopping experience. In production facilities, live pallet racking systems play a crucial role in managing raw materials and finished goods. These systems help streamline the production process by ensuring that materials are readily available when needed, reducing downtime and increasing productivity. By organizing materials in a systematic manner, live pallet racking also aids in maintaining a clean and efficient workspace, which is essential for safety and quality control. Workshops, which often deal with a variety of tools and components, benefit from live pallet racking systems by improving the organization and accessibility of these items. By providing a structured storage solution, live pallet racking helps workshops maintain an orderly environment, reducing the time spent searching for tools and parts and allowing workers to focus on their tasks. In other areas, such as automotive, pharmaceuticals, and food and beverage industries, live pallet racking systems are used to address specific storage challenges. For instance, in the automotive industry, these systems can be used to store heavy and bulky parts, while in the pharmaceutical industry, they help manage sensitive products that require careful handling and storage. In the food and beverage sector, live pallet racking ensures that perishable goods are stored in a manner that maintains their freshness and quality. Overall, the Global Live Pallet Racking Market offers versatile and efficient storage solutions that cater to the diverse needs of various industries. By optimizing space utilization and improving the flow of goods, these systems help businesses enhance their operational efficiency, reduce costs, and improve customer satisfaction.

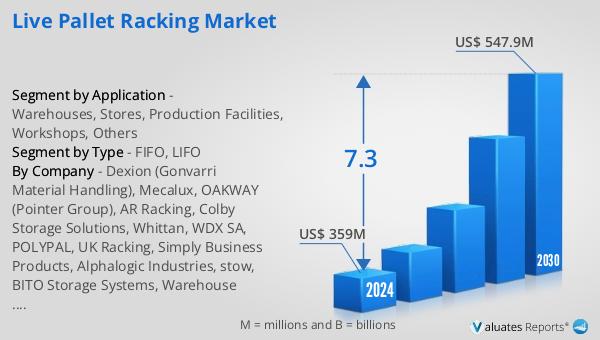

Global Live Pallet Racking Market Outlook:

The worldwide Live Pallet Racking market is anticipated to expand from $359 million in 2024 to $547.9 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 7.3% throughout the forecast period. Insights from our Construction Machinery research center reveal that sales of construction machinery in Europe surged by 24% in 2021. In 2022, the construction machinery sector in Europe generated approximately $22 billion in revenue, while the U.S. market recorded sales of about $36 billion in construction machinery. Asian companies hold a dominant position, accounting for 50% of the revenue, followed by Europe and North America, which contribute 26% and 23%, respectively. This growth trajectory underscores the increasing demand for efficient storage solutions across various industries, driven by the need to optimize supply chain operations and enhance inventory management. As businesses continue to seek ways to improve their operational efficiency, the adoption of live pallet racking systems is expected to rise, offering significant benefits in terms of space utilization, cost reduction, and improved inventory turnover. The market's expansion is further supported by advancements in technology and the growing emphasis on sustainability, which are driving the development of innovative and eco-friendly storage solutions.

| Report Metric | Details |

| Report Name | Live Pallet Racking Market |

| Accounted market size in 2024 | US$ 359 million |

| Forecasted market size in 2030 | US$ 547.9 million |

| CAGR | 7.3 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Dexion (Gonvarri Material Handling), Mecalux, OAKWAY (Pointer Group), AR Racking, Colby Storage Solutions, Whittan, WDX SA, POLYPAL, UK Racking, Simply Business Products, Alphalogic Industries, stow, BITO Storage Systems, Warehouse Systems, Avanta, Prodek, Noega Systems, Brännehylte Lagersystem AB |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |