What is Global Conventional Pallet Racks Market?

The Global Conventional Pallet Racks Market refers to the industry focused on the production and distribution of traditional pallet racking systems. These systems are essential for organizing and storing goods in various settings, such as warehouses, retail stores, and manufacturing facilities. Conventional pallet racks are designed to hold pallets loaded with products, allowing for efficient use of vertical space and easy access to stored items. They are typically made from steel and can be customized to fit different storage needs, including varying heights, depths, and load capacities. The market for these racks is driven by the growing demand for efficient storage solutions, particularly in industries that require large-scale inventory management. As businesses continue to expand and optimize their supply chains, the need for reliable and cost-effective storage systems like conventional pallet racks is expected to increase. This market is characterized by a wide range of products, from basic shelving units to more complex systems with integrated technology for inventory tracking and management.

Single Rows, Double Rows in the Global Conventional Pallet Racks Market:

In the Global Conventional Pallet Racks Market, single rows and double rows are two common configurations that cater to different storage needs. Single row pallet racks are designed to be placed against a wall or as standalone units, providing access to goods from one side. This configuration is ideal for smaller spaces or when the inventory turnover rate is high, as it allows for quick and easy retrieval of items. Single row racks are often used in retail environments or smaller warehouses where space is limited, and accessibility is crucial. They are also suitable for storing products that require frequent restocking or rotation, as they offer direct access to each pallet without the need to move other items. On the other hand, double row pallet racks, also known as back-to-back racks, consist of two rows of racks placed together, allowing access from both sides. This configuration maximizes storage density by utilizing the available floor space more efficiently. Double row racks are commonly used in larger warehouses and distribution centers where space optimization is a priority. They are ideal for storing large quantities of products that do not require frequent access, as the double row setup can make it more challenging to reach items stored in the middle. However, this configuration is highly efficient for bulk storage and is often used in industries such as manufacturing and logistics, where large volumes of goods need to be stored and managed. Both single and double row pallet racks can be customized to meet specific storage requirements, including varying heights, depths, and load capacities. They can also be equipped with additional features such as wire decking, safety bars, and pallet supports to enhance their functionality and safety. The choice between single and double row configurations depends on factors such as available space, inventory turnover rate, and the type of products being stored. Businesses must carefully assess their storage needs and operational requirements to determine the most suitable configuration for their conventional pallet racks. In addition to single and double row configurations, the Global Conventional Pallet Racks Market offers a variety of other options to cater to diverse storage needs. These include drive-in and drive-through racks, which allow forklifts to enter the rack structure for loading and unloading, and push-back racks, which use a system of carts and rails to store pallets in a dense, multi-deep configuration. Each of these options has its own advantages and is designed to address specific storage challenges, such as maximizing space utilization or improving accessibility. Overall, the Global Conventional Pallet Racks Market provides a wide range of solutions to meet the diverse storage needs of businesses across various industries. Whether it's a small retail store or a large distribution center, conventional pallet racks offer a reliable and cost-effective way to organize and manage inventory. By choosing the right configuration and features, businesses can optimize their storage space, improve operational efficiency, and enhance their overall supply chain performance.

Warehouses, Stores, Production Facilities, Workshops, Others in the Global Conventional Pallet Racks Market:

The Global Conventional Pallet Racks Market plays a crucial role in various areas, including warehouses, stores, production facilities, workshops, and other settings. In warehouses, conventional pallet racks are essential for organizing and storing large volumes of goods. They allow for efficient use of vertical space, enabling warehouses to store more products without expanding their footprint. This is particularly important in industries with high inventory turnover rates, such as retail and e-commerce, where quick and easy access to goods is crucial for meeting customer demands. Conventional pallet racks also help improve warehouse safety by keeping products off the floor and reducing the risk of accidents. In retail stores, conventional pallet racks are used to store and display products in an organized manner. They provide a sturdy and reliable solution for holding heavy or bulky items, such as appliances, furniture, and building materials. By using pallet racks, retailers can maximize their floor space and create an efficient layout that enhances the shopping experience for customers. Additionally, pallet racks can be customized with features such as signage and lighting to improve product visibility and attract customers' attention. Production facilities also benefit from the use of conventional pallet racks, as they provide a convenient way to store raw materials, work-in-progress items, and finished goods. By organizing materials and products on pallet racks, production facilities can streamline their operations and reduce the time and effort required for material handling. This leads to increased productivity and efficiency, as workers can quickly locate and retrieve the items they need. Furthermore, pallet racks help maintain a clean and organized workspace, which is essential for ensuring product quality and safety. In workshops, conventional pallet racks are used to store tools, equipment, and supplies in an organized manner. They provide a durable and flexible storage solution that can be easily adjusted to accommodate different sizes and types of items. By using pallet racks, workshops can optimize their space and improve workflow, as workers can quickly access the tools and materials they need for their tasks. This not only enhances productivity but also helps maintain a safe and efficient working environment. Other areas where conventional pallet racks are used include distribution centers, automotive facilities, and agricultural operations. In distribution centers, pallet racks are essential for managing large volumes of goods and ensuring timely order fulfillment. In automotive facilities, they are used to store parts and components, while in agricultural operations, they provide a convenient way to store equipment and supplies. Overall, the Global Conventional Pallet Racks Market offers versatile and reliable storage solutions that cater to the diverse needs of businesses across various industries. By investing in high-quality pallet racks, businesses can improve their storage efficiency, enhance their operational performance, and ultimately achieve greater success.

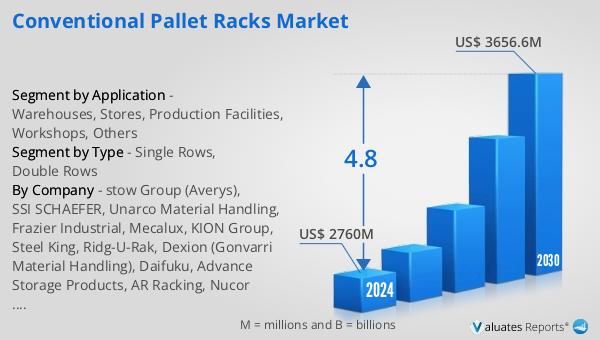

Global Conventional Pallet Racks Market Outlook:

The outlook for the Global Conventional Pallet Racks Market indicates a promising growth trajectory. It is anticipated that the market will expand from a valuation of approximately US$ 2760 million in 2024 to around US$ 3656.6 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 4.8% over the forecast period. This growth is driven by the increasing demand for efficient storage solutions across various industries. According to insights from our Construction Machinery research center, the sales of construction machinery in Europe saw a significant increase of 24% in 2021. In 2022, the revenue generated from construction machinery in Europe was approximately US$ 22 billion, while the United States market recorded sales of about US$ 36 billion in the same year. Asian companies have established a dominant position in the market, accounting for 50% of the total revenue, followed by Europe and North America, which contribute 26% and 23%, respectively. This data underscores the robust demand for conventional pallet racks as businesses seek to optimize their storage capabilities and enhance their supply chain efficiency. The market's growth is further supported by advancements in technology and the increasing adoption of automated storage and retrieval systems, which complement the use of conventional pallet racks in modern warehousing and logistics operations.

| Report Metric | Details |

| Report Name | Conventional Pallet Racks Market |

| Accounted market size in 2024 | US$ 2760 million |

| Forecasted market size in 2030 | US$ 3656.6 million |

| CAGR | 4.8 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | stow Group (Averys), SSI SCHAEFER, Unarco Material Handling, Frazier Industrial, Mecalux, KION Group, Steel King, Ridg-U-Rak, Dexion (Gonvarri Material Handling), Daifuku, Advance Storage Products, AR Racking, Nucor Warehouse Systems, Nedcon, Rack Builders, North American Steel, Konstant, Speedrack, Nanjing Inform, JINGXING, Nanjing Kingmore, Nanjing Eurasia, Jiangsu NOVA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |