What is Global Laminated Sand Core Injection Machine Market?

The Global Laminated Sand Core Injection Machine Market is a specialized segment within the manufacturing industry that focuses on machines used for creating sand cores. These cores are essential components in the metal casting process, where they form the internal cavities of cast parts. The laminated sand core injection machine is designed to inject a mixture of sand and a binding agent into a core box, which is then cured to form a solid core. This technology is crucial for producing complex and precise metal components, as it allows for the creation of intricate internal geometries that would be difficult or impossible to achieve with traditional casting methods. The market for these machines is driven by the demand for high-quality castings in various industries, including automotive, aerospace, and industrial machinery. As industries continue to seek more efficient and precise manufacturing processes, the demand for advanced sand core injection machines is expected to grow. These machines not only improve the quality and accuracy of cast parts but also enhance production efficiency by reducing waste and minimizing the need for post-casting machining. The global market is characterized by technological advancements, with manufacturers focusing on developing machines that offer greater automation, precision, and energy efficiency.

Automatic, Semi Automatic in the Global Laminated Sand Core Injection Machine Market:

In the Global Laminated Sand Core Injection Machine Market, machines are typically categorized into two main types: Automatic and Semi-Automatic. Automatic machines are designed to operate with minimal human intervention, offering high levels of precision and efficiency. These machines are equipped with advanced control systems that allow for the precise injection of sand and binding agents into the core box, ensuring consistent quality and reducing the likelihood of defects. Automatic machines are ideal for high-volume production environments where speed and accuracy are critical. They often feature integrated systems for core handling, curing, and ejection, streamlining the entire core-making process. This level of automation not only enhances productivity but also reduces labor costs and the potential for human error. On the other hand, Semi-Automatic machines require some level of manual operation, typically in the loading and unloading of core boxes or the adjustment of machine settings. While they may not offer the same level of efficiency as their automatic counterparts, semi-automatic machines provide greater flexibility and are often more cost-effective for smaller production runs or specialized applications. They allow operators to make adjustments on the fly, accommodating variations in core design or material properties. Both types of machines play a crucial role in the market, catering to different production needs and budget constraints. As the demand for high-quality cast components continues to rise, manufacturers are investing in both automatic and semi-automatic machines to enhance their production capabilities. The choice between the two often depends on factors such as production volume, complexity of the cores, and available budget. In recent years, there has been a trend towards greater automation in the industry, driven by the need for increased efficiency and precision. However, semi-automatic machines remain popular in certain sectors where flexibility and cost considerations are paramount. Overall, the Global Laminated Sand Core Injection Machine Market is characterized by a diverse range of machines that cater to the varying needs of manufacturers across different industries. As technology continues to evolve, we can expect to see further advancements in both automatic and semi-automatic machines, offering even greater levels of efficiency, precision, and versatility.

Mechanical Engineering, Automotive Industry, Aerospace, Oil And Gas, Chemical Industry, Medical Technology, Electrical Industry in the Global Laminated Sand Core Injection Machine Market:

The Global Laminated Sand Core Injection Machine Market finds extensive usage across various industries, each benefiting from the unique capabilities of these machines. In Mechanical Engineering, these machines are essential for producing complex cast components with precise internal geometries. They enable engineers to design parts that are both lightweight and strong, optimizing performance and efficiency. In the Automotive Industry, laminated sand core injection machines are used to manufacture engine blocks, cylinder heads, and other critical components. The ability to create intricate internal passages for fluid flow and cooling is crucial for enhancing engine performance and fuel efficiency. In the Aerospace sector, these machines play a vital role in producing lightweight yet durable components for aircraft engines and structural parts. The precision offered by these machines ensures that aerospace components meet stringent safety and performance standards. In the Oil and Gas industry, laminated sand core injection machines are used to produce components for drilling equipment and pipelines. The ability to create complex internal geometries is essential for optimizing fluid flow and ensuring the reliability of critical infrastructure. In the Chemical Industry, these machines are used to manufacture components for reactors and processing equipment, where precise internal geometries are necessary for efficient chemical reactions. In Medical Technology, laminated sand core injection machines are used to produce components for medical devices and equipment, where precision and reliability are paramount. Finally, in the Electrical Industry, these machines are used to manufacture components for transformers and other electrical equipment, where complex internal geometries are required for optimal performance. Across all these industries, the Global Laminated Sand Core Injection Machine Market plays a crucial role in enabling the production of high-quality, precise, and efficient components that meet the demanding requirements of modern manufacturing.

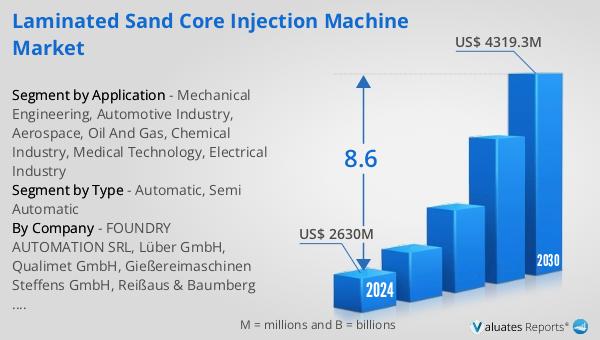

Global Laminated Sand Core Injection Machine Market Outlook:

The outlook for the Global Laminated Sand Core Injection Machine Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of US$ 2630 million in 2024 to an impressive US$ 4319.3 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 8.6% during the forecast period. This robust growth can be attributed to several factors, including the increasing demand for high-quality cast components across various industries such as automotive, aerospace, and industrial machinery. As these industries continue to evolve and seek more efficient manufacturing processes, the need for advanced sand core injection machines is expected to rise. The market is also likely to benefit from technological advancements, with manufacturers focusing on developing machines that offer greater automation, precision, and energy efficiency. Additionally, the growing emphasis on reducing waste and minimizing the need for post-casting machining is expected to drive the adoption of these machines. As a result, the Global Laminated Sand Core Injection Machine Market is poised for significant growth, offering numerous opportunities for manufacturers and investors alike. This positive outlook underscores the importance of these machines in modern manufacturing and highlights their potential to drive innovation and efficiency across various industries.

| Report Metric | Details |

| Report Name | Laminated Sand Core Injection Machine Market |

| Accounted market size in 2024 | US$ 2630 million |

| Forecasted market size in 2030 | US$ 4319.3 million |

| CAGR | 8.6 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | FOUNDRY AUTOMATION SRL, Lüber GmbH, Qualimet GmbH, Gießereimaschinen Steffens GmbH, Reißaus & Baumberg Maschinenbau GmbH, AHB Giessereitechnik GmbH, BRANDES GMBH GIESSEREIAUTOMATION, DISA Industrieanlagen GmbH Leipzig, Fiss-machines Klaus Friedrich, HICONFORM, KARCHER-GUSS GmbH, Klann Maschinen, manfred hamann & söhne GbR, Muschna Giesserei-Maschinen GmbH, Willer GmbH, S-MA GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |