What is Epoxy-based Conductive Adhesives - Global Market?

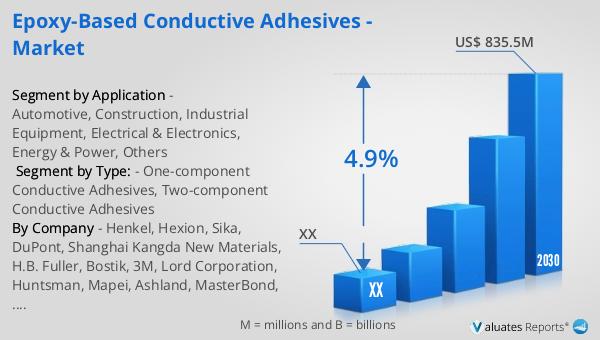

Epoxy-based conductive adhesives are specialized materials used to create electrical connections between components in various applications. These adhesives are formulated with epoxy resins, which provide strong mechanical properties and excellent adhesion, and conductive fillers, such as silver or carbon, which enable electrical conductivity. The global market for these adhesives is driven by their increasing use in industries like electronics, automotive, and aerospace, where they serve as alternatives to traditional soldering methods. They offer advantages such as lower processing temperatures, flexibility, and the ability to bond dissimilar materials. As technology advances and the demand for miniaturized and more efficient electronic devices grows, the need for reliable and effective conductive adhesives is expected to rise. This market is characterized by continuous innovation, with manufacturers focusing on improving the performance and environmental sustainability of their products. The global market for epoxy-based conductive adhesives was valued at approximately $581 million in 2023 and is projected to reach around $835.5 million by 2030, growing at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth reflects the expanding applications and technological advancements in the field.

One-component Conductive Adhesives, Two-component Conductive Adhesives in the Epoxy-based Conductive Adhesives - Global Market:

One-component conductive adhesives are a type of epoxy-based adhesive that comes pre-mixed and ready to use, requiring no additional mixing or preparation before application. These adhesives are particularly valued for their convenience and ease of use, as they eliminate the need for precise mixing ratios and reduce the potential for human error during preparation. They are typically cured through heat, which activates the adhesive properties and solidifies the bond. One-component adhesives are widely used in applications where speed and efficiency are critical, such as in high-volume manufacturing processes. They are often employed in the electronics industry for bonding components on printed circuit boards (PCBs), where they provide reliable electrical connections and mechanical stability. The simplicity of one-component adhesives makes them an attractive option for manufacturers looking to streamline their production processes and reduce labor costs. On the other hand, two-component conductive adhesives consist of separate resin and hardener components that must be mixed together before application. This type of adhesive offers greater flexibility in terms of formulation and performance characteristics, as the mixing ratio can be adjusted to achieve specific properties. Two-component adhesives are often used in applications that require customized solutions, such as in the automotive and aerospace industries, where specific performance criteria must be met. These adhesives are known for their strong bonding capabilities and resistance to harsh environmental conditions, making them suitable for demanding applications. The global market for epoxy-based conductive adhesives includes both one-component and two-component products, each catering to different industry needs and application requirements. As the demand for advanced electronic devices and systems continues to grow, the market for these adhesives is expected to expand, driven by the need for reliable and efficient bonding solutions. Manufacturers are investing in research and development to enhance the performance of both one-component and two-component adhesives, focusing on improving conductivity, adhesion strength, and environmental sustainability. The choice between one-component and two-component adhesives often depends on the specific application requirements, with factors such as curing time, mechanical properties, and environmental resistance playing a crucial role in the decision-making process. As industries continue to evolve and new technologies emerge, the demand for versatile and high-performance conductive adhesives is likely to increase, supporting the growth of the global market.

Automotive, Construction, Industrial Equipment, Electrical & Electronics, Energy & Power, Others in the Epoxy-based Conductive Adhesives - Global Market:

Epoxy-based conductive adhesives are used in a variety of industries due to their unique properties and versatility. In the automotive sector, these adhesives are employed for bonding electronic components within vehicles, such as sensors, control units, and infotainment systems. They provide reliable electrical connections and mechanical stability, which are essential for the performance and safety of modern vehicles. The ability of epoxy-based adhesives to withstand harsh environmental conditions, such as temperature fluctuations and vibrations, makes them ideal for automotive applications. In the construction industry, these adhesives are used for bonding and sealing applications where electrical conductivity is required. They are often utilized in the installation of heating systems, such as underfloor heating, where they ensure efficient energy transfer and system reliability. The industrial equipment sector also benefits from the use of epoxy-based conductive adhesives, particularly in the assembly and maintenance of machinery and equipment. These adhesives provide strong bonds and electrical connections, which are crucial for the operation and longevity of industrial systems. In the electrical and electronics industry, epoxy-based conductive adhesives are widely used for assembling and repairing electronic devices and components. They offer an alternative to traditional soldering methods, providing flexibility and the ability to bond dissimilar materials. These adhesives are commonly used in the production of printed circuit boards (PCBs), where they ensure reliable electrical connections and mechanical stability. The energy and power sector also utilizes epoxy-based conductive adhesives for various applications, such as in the assembly of solar panels and wind turbines. These adhesives provide strong bonds and electrical conductivity, which are essential for the efficient operation of renewable energy systems. Additionally, epoxy-based conductive adhesives are used in other industries, such as aerospace and telecommunications, where they offer reliable bonding solutions for critical applications. The versatility and performance of these adhesives make them a valuable tool in a wide range of industries, supporting the growth of the global market.

Epoxy-based Conductive Adhesives - Global Market Outlook:

The global market for epoxy-based conductive adhesives was valued at approximately $581 million in 2023 and is projected to reach around $835.5 million by 2030, growing at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth reflects the expanding applications and technological advancements in the field. The North American market for epoxy-based conductive adhesives was valued at an undisclosed amount in 2023 and is expected to grow at a certain CAGR from 2024 to 2030. This growth is driven by the increasing demand for advanced electronic devices and systems, as well as the need for reliable and efficient bonding solutions in various industries. The market is characterized by continuous innovation, with manufacturers focusing on improving the performance and environmental sustainability of their products. As technology advances and the demand for miniaturized and more efficient electronic devices grows, the need for reliable and effective conductive adhesives is expected to rise. The global market for epoxy-based conductive adhesives is expected to continue its growth trajectory, driven by the increasing demand for advanced electronic devices and systems, as well as the need for reliable and efficient bonding solutions in various industries.

| Report Metric | Details |

| Report Name | Epoxy-based Conductive Adhesives - Market |

| Forecasted market size in 2030 | US$ 835.5 million |

| CAGR | 4.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, Hexion, Sika, DuPont, Shanghai Kangda New Materials, H.B. Fuller, Bostik, 3M, Lord Corporation, Huntsman, Mapei, Ashland, MasterBond, ITW Performance Polymers, Adhesives Technology Corp, Jowat Adhesives, Permabond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |