What is Brick Machines - Global Market?

Brick machines are essential tools in the construction industry, designed to produce bricks efficiently and consistently. These machines are pivotal in the global market, catering to the increasing demand for bricks in various construction projects. The global market for brick machines encompasses a wide range of equipment, from manual to fully automated systems, each serving different scales of production needs. The market is driven by the growing construction activities worldwide, urbanization, and the need for sustainable building materials. Brick machines are not only used in large-scale industrial projects but also in smaller construction sites, making them versatile and indispensable. The market is characterized by technological advancements that enhance the efficiency and output of these machines, making them more cost-effective and environmentally friendly. As the demand for construction materials continues to rise, the global market for brick machines is expected to grow, offering numerous opportunities for manufacturers and investors alike. The market's growth is also supported by the increasing adoption of automation in the construction industry, which enhances productivity and reduces labor costs.

Automatic, Semi-Automatic in the Brick Machines - Global Market:

Automatic and semi-automatic brick machines are two primary categories within the global brick machine market, each offering distinct advantages and catering to different production needs. Automatic brick machines are designed to operate with minimal human intervention, utilizing advanced technology to streamline the brick-making process. These machines are equipped with sophisticated control systems that manage the entire production line, from raw material feeding to brick molding and stacking. The automation ensures high precision and consistency in brick production, significantly reducing the chances of human error. Automatic machines are ideal for large-scale production facilities where high output and efficiency are paramount. They are capable of producing a wide variety of brick types and sizes, catering to diverse construction requirements. The initial investment for automatic machines is higher compared to semi-automatic ones, but the long-term benefits in terms of labor savings and production efficiency often justify the cost. On the other hand, semi-automatic brick machines require some level of human intervention, particularly in the feeding and stacking processes. These machines are typically more affordable than their fully automatic counterparts, making them accessible to smaller businesses and construction sites with limited budgets. Semi-automatic machines offer a balance between manual labor and automation, providing flexibility in production while still enhancing efficiency compared to fully manual methods. They are suitable for medium-scale production needs where the demand for bricks is steady but not overwhelming. The semi-automatic machines allow operators to have more control over the production process, which can be advantageous in situations where customization or adjustments are needed. Both automatic and semi-automatic brick machines contribute significantly to the global market by addressing different segments of the construction industry. The choice between the two depends largely on the scale of production, budget constraints, and specific project requirements. As technology continues to advance, both types of machines are becoming more efficient and environmentally friendly, incorporating features such as energy-saving mechanisms and the ability to use recycled materials. This evolution not only enhances the sustainability of brick production but also aligns with the global push towards greener construction practices. In summary, the global market for brick machines is diverse, with automatic and semi-automatic machines playing crucial roles in meeting the varied demands of the construction industry. Automatic machines offer high efficiency and precision for large-scale operations, while semi-automatic machines provide a cost-effective solution for medium-scale production. Both types of machines are integral to the industry's growth, driven by technological advancements and the increasing need for sustainable building solutions. As the market continues to evolve, manufacturers are likely to focus on enhancing the capabilities of these machines, ensuring they remain competitive and relevant in a rapidly changing construction landscape.

Industrial, Construction Industry, Others in the Brick Machines - Global Market:

Brick machines play a vital role in various sectors, including industrial, construction, and other areas, by providing efficient solutions for brick production. In the industrial sector, brick machines are used to produce high-quality bricks that are essential for building durable structures. Industries that require large-scale infrastructure, such as manufacturing plants, warehouses, and factories, rely heavily on brick machines to meet their construction needs. The ability to produce bricks on-site or in close proximity to the construction area reduces transportation costs and ensures a steady supply of materials, which is crucial for maintaining project timelines and budgets. In the construction industry, brick machines are indispensable tools for building residential, commercial, and public structures. The demand for bricks in this sector is driven by urbanization and the need for affordable housing solutions. Brick machines enable construction companies to produce a wide range of brick types, including standard, hollow, and interlocking bricks, catering to different architectural designs and structural requirements. The versatility of brick machines allows for customization in brick production, ensuring that the specific needs of each project are met. This adaptability is particularly important in regions with diverse building codes and standards. Beyond industrial and construction applications, brick machines are also used in other areas such as landscaping and road construction. In landscaping, bricks are used to create aesthetically pleasing pathways, garden walls, and outdoor living spaces. Brick machines provide the flexibility to produce bricks in various shapes, sizes, and colors, allowing for creative and unique designs. In road construction, bricks are used for paving and creating durable surfaces that can withstand heavy traffic and environmental conditions. The use of brick machines in these areas highlights their versatility and the wide range of applications they support. Overall, the usage of brick machines in industrial, construction, and other sectors underscores their importance in modern infrastructure development. These machines not only enhance the efficiency and cost-effectiveness of brick production but also contribute to the sustainability of construction practices by enabling the use of eco-friendly materials and processes. As the demand for bricks continues to grow across various sectors, brick machines will remain a critical component of the global construction landscape, supporting the development of resilient and sustainable infrastructure.

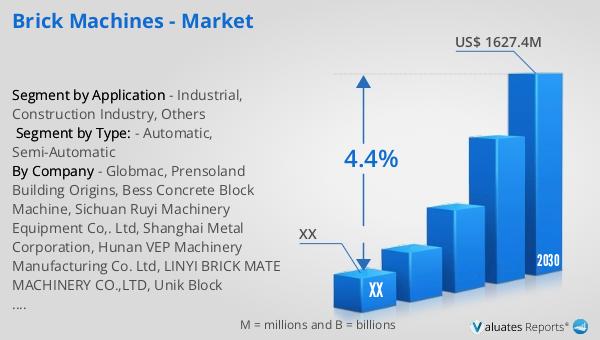

Brick Machines - Global Market Outlook:

The global market for brick machines was valued at approximately USD 1,206.9 million in 2023, with projections indicating a growth to around USD 1,627.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.4% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for efficient and sustainable construction solutions worldwide. However, it's important to note that the construction machinery industry faced challenges in 2022, as reported by the China Machinery Industry Federation. The industry's operating income experienced a decline of over 12% during that year. This downturn was attributed to various factors, including economic uncertainties and disruptions in supply chains. Despite these challenges, the brick machine market is expected to recover and grow, driven by technological advancements and the rising need for construction materials. The market's resilience is supported by the ongoing urbanization and infrastructure development projects globally, which continue to fuel the demand for bricks and brick-making machinery. As the industry adapts to changing market dynamics, manufacturers are likely to focus on innovation and efficiency to maintain competitiveness and meet the evolving needs of the construction sector.

| Report Metric | Details |

| Report Name | Brick Machines - Market |

| Forecasted market size in 2030 | US$ 1627.4 million |

| CAGR | 4.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Globmac, Prensoland Building Origins, Bess Concrete Block Machine, Sichuan Ruyi Machinery Equipment Co,. Ltd, Shanghai Metal Corporation, Hunan VEP Machinery Manufacturing Co. Ltd, LINYI BRICK MATE MACHINERY CO.,LTD, Unik Block Machines, Hongfa Machine, Fulang Machine, Queen Machinery Co.,Ltd, Competitive Landscape, Quangong Machinery, Zhongcai Jianke, QUNFENG MACHINERY, XIEXING MACHINERY, Hengxing Industry Machinery, Huayuan Machinery, YIXIN MACHINERY, Huaxing, Zhengzhou Tianyi Machinery, LIUSHI MACHINERY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |