What is Brick Machine Moulds - Global Market?

Brick machine moulds are essential components in the construction industry, playing a crucial role in shaping and forming bricks used for various building projects. These moulds are designed to create bricks of specific shapes and sizes, ensuring uniformity and precision in construction materials. The global market for brick machine moulds is driven by the increasing demand for construction activities worldwide, fueled by urbanization and infrastructure development. As cities expand and new buildings are erected, the need for high-quality bricks becomes paramount, leading to a growing market for these moulds. Manufacturers are continuously innovating to produce moulds that cater to diverse construction needs, including different brick shapes and sizes. The market is characterized by a wide range of products, from standard brick moulds to specialized ones for unique architectural designs. This diversity allows builders to choose moulds that best suit their project requirements, enhancing the efficiency and aesthetics of construction. As the construction industry continues to evolve, the demand for advanced brick machine moulds is expected to rise, making it a dynamic and vital segment of the global market.

Porous Standard Brick Mould, Hollow Brick Mould, Pavement I-Brick Mould, Hexagonal Brick Mould, Hollow Porous Brick Mould, Others in the Brick Machine Moulds - Global Market:

Brick machine moulds come in various types, each designed to produce specific kinds of bricks that serve different construction purposes. The porous standard brick mould is commonly used for creating bricks with small holes, which help in reducing the weight of the bricks and improving their insulation properties. These bricks are often used in residential buildings where thermal efficiency is a priority. Hollow brick moulds, on the other hand, are designed to produce bricks with larger cavities. These bricks are lighter and provide better insulation, making them ideal for high-rise buildings and structures where weight reduction is crucial. Pavement I-brick moulds are specifically crafted for creating interlocking bricks used in paving roads and pathways. These bricks are known for their durability and ability to withstand heavy traffic, making them a popular choice for urban infrastructure projects. Hexagonal brick moulds produce uniquely shaped bricks that are often used for decorative purposes in landscaping and architectural designs. These bricks add an aesthetic appeal to outdoor spaces, such as gardens and parks. Hollow porous brick moulds combine the features of hollow and porous bricks, offering both weight reduction and improved insulation. These bricks are versatile and can be used in a variety of construction projects, from residential to commercial buildings. Other types of brick machine moulds cater to specialized needs, such as fire-resistant bricks or bricks with enhanced acoustic properties. The global market for these moulds is diverse, with manufacturers offering a wide range of products to meet the specific demands of the construction industry. As technology advances, the development of more efficient and versatile moulds continues to drive the market forward, providing builders with the tools they need to create innovative and sustainable structures.

Urban Road, Highway, Airports, Parks, Others in the Brick Machine Moulds - Global Market:

Brick machine moulds are utilized in various construction areas, each serving a unique purpose to enhance the infrastructure and aesthetics of the environment. In urban road construction, these moulds are used to produce bricks that form the foundation and surface of roads. The bricks created using pavement I-brick moulds are particularly popular in urban settings due to their interlocking design, which provides stability and durability to withstand the constant pressure of vehicular traffic. These bricks also offer a visually appealing finish, contributing to the overall aesthetic of cityscapes. In highway construction, hollow brick moulds are often employed to produce bricks that are lightweight yet strong, reducing the overall weight of the structure while maintaining its integrity. This is crucial for highways, where the load-bearing capacity is a significant concern. Airports also benefit from the use of brick machine moulds, particularly in the construction of runways and taxiways. The durability and strength of bricks produced using these moulds ensure that the surfaces can handle the heavy loads and constant use typical of airport operations. In parks, hexagonal brick moulds are frequently used to create decorative pathways and seating areas. These uniquely shaped bricks add an artistic touch to the landscape, enhancing the visual appeal of recreational spaces. Other areas, such as residential and commercial buildings, also utilize brick machine moulds to produce bricks that meet specific architectural and functional requirements. The versatility of these moulds allows for the creation of bricks that cater to various needs, from thermal insulation to acoustic performance. As the demand for sustainable and efficient construction materials grows, the use of brick machine moulds in these areas is expected to increase, driving innovation and development in the global market.

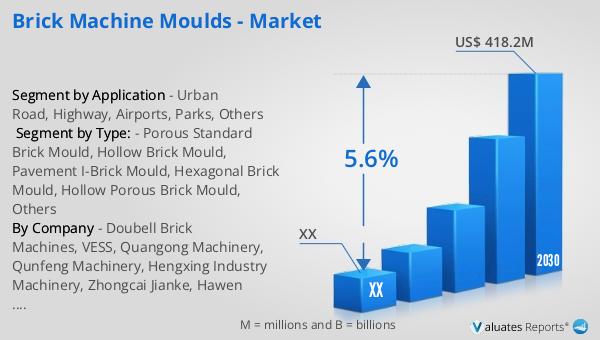

Brick Machine Moulds - Global Market Outlook:

The global market for brick machine moulds was valued at approximately $289.6 million in 2023, with projections indicating a growth to around $418.2 million by 2030. This represents a compound annual growth rate (CAGR) of 5.6% over the forecast period from 2024 to 2030. This growth is driven by the increasing demand for construction activities worldwide, as urbanization and infrastructure development continue to expand. However, it's important to note that the construction machinery industry faced challenges in 2022, with the China Machinery Industry Federation reporting a decline in operating income by more than 12%. This downturn highlights the volatility and challenges within the industry, which can impact the market for brick machine moulds. Despite these challenges, the market is expected to recover and grow, driven by technological advancements and the increasing need for efficient and sustainable construction materials. Manufacturers are focusing on developing innovative moulds that cater to the evolving needs of the construction industry, ensuring that the market remains dynamic and competitive. As the global construction landscape continues to change, the demand for high-quality brick machine moulds is likely to increase, providing opportunities for growth and development in this vital sector.

| Report Metric | Details |

| Report Name | Brick Machine Moulds - Market |

| Forecasted market size in 2030 | US$ 418.2 million |

| CAGR | 5.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Doubell Brick Machines, VESS, Quangong Machinery, Qunfeng Machinery, Hengxing Industry Machinery, Zhongcai Jianke, Hawen Machinery, Changsheng Machinery, YIXIN MACHINERY, LIUSHI MACHINERY, Yixin, Huayuan Machinery, Yufeng Machinery, GYM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |