What is Articulated Material Handling Robots - Global Market?

Articulated Material Handling Robots are a specialized type of industrial robot designed to automate the process of moving materials within a manufacturing or production environment. These robots are characterized by their jointed arm design, which allows for a high degree of flexibility and precision in handling tasks. They are widely used in various industries to improve efficiency, reduce labor costs, and enhance safety by taking over repetitive or hazardous tasks. The global market for these robots has been expanding due to the increasing demand for automation and the need for more efficient production processes. Companies across the globe are investing in articulated robots to streamline operations and maintain competitiveness in a rapidly evolving market. The versatility of these robots makes them suitable for a wide range of applications, from simple pick-and-place tasks to complex assembly operations. As industries continue to embrace automation, the demand for articulated material handling robots is expected to grow, driven by advancements in technology and the need for more sophisticated manufacturing solutions.

< 5 Kg, 5 - 10 Kg, > 10 Kg in the Articulated Material Handling Robots - Global Market:

In the global market for articulated material handling robots, these machines are categorized based on their payload capacity, which refers to the maximum weight they can handle. Robots with a payload capacity of less than 5 kg are typically used for light-duty tasks. These robots are ideal for industries where precision and speed are crucial, such as electronics and small parts assembly. Their lightweight design allows them to operate at high speeds, making them perfect for tasks that require quick and accurate movements. On the other hand, robots with a payload capacity between 5 to 10 kg are more versatile and can handle a wider range of tasks. They are commonly used in industries like automotive and consumer goods, where they can perform tasks such as assembly, packaging, and material handling. These robots offer a balance between speed and strength, making them suitable for medium-duty applications. Finally, robots with a payload capacity of more than 10 kg are designed for heavy-duty tasks. These robots are used in industries such as metal and machinery, where they can handle large and heavy components. Their robust design allows them to perform tasks that require significant force, such as welding, cutting, and heavy lifting. The demand for these robots is driven by the need for automation in industries that deal with large and heavy materials. As the global market for articulated material handling robots continues to grow, manufacturers are focusing on developing robots with higher payload capacities and enhanced capabilities to meet the evolving needs of various industries. The advancements in technology, such as improved sensors and control systems, are enabling these robots to perform more complex tasks with greater precision and efficiency. This is leading to increased adoption of articulated robots across different sectors, as companies seek to improve productivity and reduce operational costs. The market is also witnessing a trend towards collaborative robots, which are designed to work alongside human workers. These robots are equipped with advanced safety features that allow them to operate safely in close proximity to humans, making them ideal for tasks that require human-robot collaboration. The growing emphasis on workplace safety and the need for flexible automation solutions are driving the demand for collaborative articulated robots. As industries continue to evolve and embrace new technologies, the global market for articulated material handling robots is expected to witness significant growth, with manufacturers focusing on developing innovative solutions to meet the diverse needs of their customers.

Automotive, Chemical, Rubber and Plastic, Electrical and Electronics, Metal and Machinery, Food, Beverages and Pharmaceuticals, Others in the Articulated Material Handling Robots - Global Market:

Articulated material handling robots are extensively used across various industries due to their versatility and efficiency. In the automotive industry, these robots are employed for tasks such as assembling parts, welding, and painting. Their precision and ability to handle repetitive tasks make them invaluable in improving production speed and quality. In the chemical, rubber, and plastic industries, articulated robots are used for handling hazardous materials, mixing, and packaging. Their ability to operate in environments that may be dangerous for humans ensures safety and efficiency. In the electrical and electronics sector, these robots are crucial for assembling small components with high precision. They help in reducing errors and increasing production rates, which is vital in a highly competitive market. The metal and machinery industry benefits from articulated robots in tasks such as cutting, welding, and assembling heavy components. Their strength and precision allow for the handling of large and heavy materials with ease. In the food, beverages, and pharmaceuticals industries, these robots are used for packaging, sorting, and quality control. Their ability to maintain hygiene standards while operating at high speeds makes them ideal for these sectors. Additionally, articulated robots are used in other industries such as logistics and warehousing, where they assist in sorting and moving goods efficiently. The adaptability of these robots to various tasks and environments makes them a valuable asset in any industry looking to improve productivity and reduce costs. As technology continues to advance, the capabilities of articulated material handling robots are expected to expand, further increasing their adoption across different sectors.

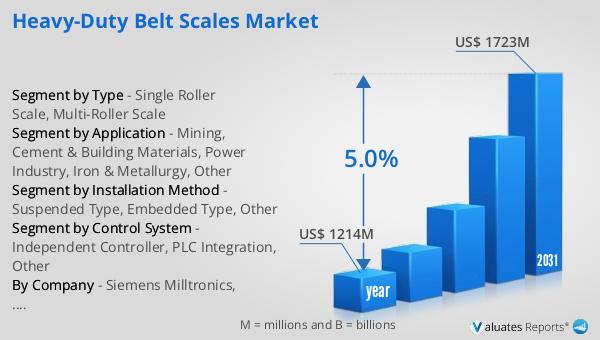

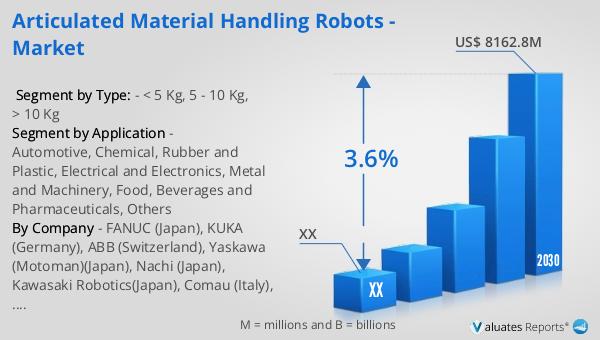

Articulated Material Handling Robots - Global Market Outlook:

The global market for articulated material handling robots was valued at approximately $6,394.9 million in 2023. It is projected to grow to a revised size of $8,162.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for automation solutions across various industries. In North America, the market for articulated material handling robots was valued at a significant amount in 2023, with expectations of continued growth through 2030. The CAGR for this region during the forecast period is anticipated to be robust, driven by technological advancements and the need for efficient production processes. The adoption of articulated robots in North America is fueled by the region's strong industrial base and the push towards automation to enhance productivity and competitiveness. As industries continue to evolve and embrace new technologies, the demand for articulated material handling robots is expected to rise, contributing to the overall growth of the global market. The focus on improving operational efficiency and reducing labor costs is driving companies to invest in these advanced robotic solutions, ensuring their place in the future of manufacturing and production.

| Report Metric | Details |

| Report Name | Articulated Material Handling Robots - Market |

| Forecasted market size in 2030 | US$ 8162.8 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | FANUC (Japan), KUKA (Germany), ABB (Switzerland), Yaskawa (Motoman)(Japan), Nachi (Japan), Kawasaki Robotics(Japan), Comau (Italy), EPSON Robots (Japan), Staubli (Switzerland), Omron Adept Technologies (US), DENSO Robotics (Japan), OTC Daihen (Japan), Toshiba (Japan), Mitsubishi Electric (Japan), Universal Robots (Denmark), Hyundai Robotics (Korea), Siasun (China), Anhui EFORT Intelligent Equipment (China), Estun Automation (China), Guangzhou CNC Equipment (China), STEP Electric Corporation (China) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |