What is Arc Light Electric Welding Electrode - Global Market?

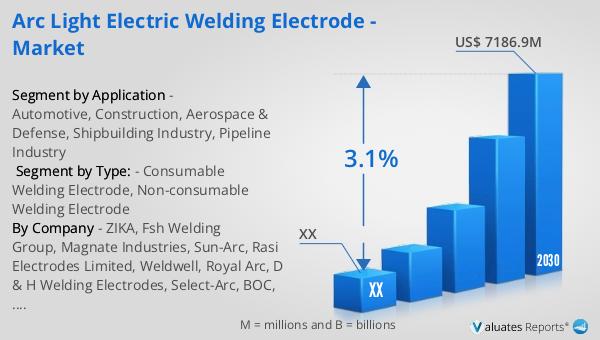

Arc Light Electric Welding Electrodes are essential components in the welding industry, serving as the medium through which electric current passes to create an arc between the electrode and the base material. This arc generates the heat necessary to melt the metals, allowing them to fuse together. The global market for these electrodes is vast and diverse, reflecting the widespread use of welding in various industries. As of 2023, the market was valued at approximately US$ 5567 million, with projections indicating growth to US$ 7186.9 million by 2030. This growth is driven by the increasing demand for welding in sectors such as construction, automotive, and shipbuilding, among others. The market is characterized by a variety of electrode types, each suited to specific applications and materials, ensuring that welding processes are efficient and effective. The steady growth rate, with a CAGR of 3.1% from 2024 to 2030, underscores the ongoing importance of welding technology in global industrial activities. The North American market, in particular, is a significant contributor to this growth, reflecting the region's robust industrial base and technological advancements in welding techniques.

Consumable Welding Electrode, Non-consumable Welding Electrode in the Arc Light Electric Welding Electrode - Global Market:

In the realm of Arc Light Electric Welding Electrodes, there are two primary categories: consumable and non-consumable electrodes. Consumable electrodes are designed to melt and become part of the weld itself. They are typically made from materials that are compatible with the base metals being welded, ensuring a strong and durable bond. These electrodes are commonly used in processes such as Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW), where the electrode not only conducts the current but also supplies filler material to the joint. The global market for consumable electrodes is driven by their versatility and efficiency, making them a staple in industries like construction and automotive manufacturing. On the other hand, non-consumable electrodes, such as those used in Gas Tungsten Arc Welding (GTAW), do not melt during the welding process. Instead, they serve solely as a conductor for the electric arc. Made from materials like tungsten, these electrodes are ideal for precision welding tasks where high-quality welds are required, such as in aerospace and defense applications. The global market for non-consumable electrodes is characterized by a demand for high-performance materials that can withstand the intense heat and stress of welding without degrading. Both types of electrodes play crucial roles in the welding industry, with their usage determined by the specific requirements of the welding task at hand. The choice between consumable and non-consumable electrodes depends on factors such as the type of metal being welded, the desired strength of the weld, and the environmental conditions in which the welding is performed. As industries continue to evolve and demand more sophisticated welding solutions, the market for both consumable and non-consumable electrodes is expected to grow, driven by innovations in materials and welding technologies. This growth is further supported by the increasing adoption of automated welding systems, which require high-quality electrodes to ensure consistent and reliable welds. The global market for Arc Light Electric Welding Electrodes is thus a dynamic and evolving landscape, reflecting the ongoing advancements in welding technology and the diverse needs of industries worldwide.

Automotive, Construction, Aerospace & Defense, Shipbuilding Industry, Pipeline Industry in the Arc Light Electric Welding Electrode - Global Market:

Arc Light Electric Welding Electrodes find extensive usage across various industries, each with its unique requirements and challenges. In the automotive industry, these electrodes are crucial for assembling vehicle bodies and components, where precision and strength are paramount. The demand for lightweight and fuel-efficient vehicles has led to the increased use of advanced materials, necessitating specialized welding techniques and electrodes. In the construction industry, welding electrodes are indispensable for erecting steel structures, bridges, and buildings. The ability to create strong, durable joints quickly and efficiently makes welding a preferred method for construction projects worldwide. The aerospace and defense sectors rely on non-consumable electrodes for tasks that require high precision and reliability, such as the fabrication of aircraft components and military equipment. These industries demand welds that can withstand extreme conditions, making the choice of electrode critical. In the shipbuilding industry, welding electrodes are used extensively for constructing and repairing ships, where the integrity of welds is vital for safety and performance. The harsh marine environment requires electrodes that can deliver robust and corrosion-resistant welds. Lastly, in the pipeline industry, welding electrodes are essential for joining pipes that transport oil, gas, and other fluids. The ability to create leak-proof and durable joints is crucial for the safe and efficient operation of pipelines. Across these industries, the global market for Arc Light Electric Welding Electrodes is driven by the need for reliable and high-performance welding solutions that can meet the specific demands of each sector. As industries continue to innovate and expand, the demand for advanced welding electrodes is expected to grow, reflecting the critical role of welding in modern industrial processes.

Arc Light Electric Welding Electrode - Global Market Outlook:

The global market outlook for Arc Light Electric Welding Electrodes indicates a promising future, with the market valued at approximately US$ 5567 million in 2023. Projections suggest that by 2030, the market will expand to a size of US$ 7186.9 million, growing at a compound annual growth rate (CAGR) of 3.1% from 2024 to 2030. This growth is indicative of the increasing demand for welding solutions across various industries, driven by technological advancements and the need for efficient and reliable welding processes. The North American market, in particular, plays a significant role in this growth trajectory, supported by a strong industrial base and continuous innovations in welding technology. Although specific figures for the North American market were not provided, it is clear that the region's contribution is substantial, reflecting its position as a leader in industrial manufacturing and technology. The steady growth rate underscores the importance of welding electrodes in global industrial activities, highlighting their role in enabling the construction of infrastructure, vehicles, and machinery that form the backbone of modern economies. As industries continue to evolve and demand more sophisticated welding solutions, the market for Arc Light Electric Welding Electrodes is poised for sustained growth, driven by the ongoing advancements in materials and welding technologies.

| Report Metric | Details |

| Report Name | Arc Light Electric Welding Electrode - Market |

| Forecasted market size in 2030 | US$ 7186.9 million |

| CAGR | 3.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ZIKA, Fsh Welding Group, Magnate Industries, Sun-Arc, Rasi Electrodes Limited, Weldwell, Royal Arc, D & H Welding Electrodes, Select-Arc, BOC, Gedik Welding, Modi Hitech, Denver, Ador Welding Ltd, Nikko Steel, TOKUDEN, Huntingdon Fusion Techniques, Royal Arc Electrodes Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |