What is Global High Temperature Micro Switches Market?

The Global High Temperature Micro Switches Market refers to the industry focused on the production and distribution of micro switches that can operate efficiently in high-temperature environments. These specialized switches are designed to function reliably in conditions where standard switches might fail due to excessive heat. High temperature micro switches are crucial in various applications, including automotive, aerospace, industrial machinery, and consumer electronics, where they ensure safety and performance by maintaining electrical connections under extreme conditions. The market for these switches is driven by the increasing demand for durable and reliable components in high-temperature applications, as industries continue to push the boundaries of technology and performance. Manufacturers in this market are continually innovating to improve the heat resistance, durability, and miniaturization of these switches to meet the evolving needs of their customers. As industries such as automotive and electronics continue to grow and require more advanced components, the demand for high temperature micro switches is expected to rise, making this a dynamic and competitive market. Companies operating in this space must focus on research and development to stay ahead of technological advancements and meet the stringent requirements of their clients.

100℃-200℃, 201℃-250℃, More than 250℃ in the Global High Temperature Micro Switches Market:

High temperature micro switches are categorized based on their operational temperature ranges, which include 100℃-200℃, 201℃-250℃, and more than 250℃. Each category serves different applications and industries, depending on the specific temperature requirements. The 100℃-200℃ range is typically used in applications where moderate heat resistance is necessary. These switches are often found in household appliances and office equipment, where they ensure reliable operation without the risk of overheating. They are designed to withstand the heat generated by everyday use, making them ideal for devices that do not experience extreme temperatures but still require dependable performance. The 201℃-250℃ range is suitable for more demanding applications, such as automotive and industrial machinery. In the automotive industry, these switches are used in engine compartments and other areas exposed to higher temperatures. They play a critical role in ensuring the safety and functionality of vehicles by maintaining electrical connections even in harsh conditions. Industrial machinery also benefits from these switches, as they can withstand the heat generated by heavy-duty operations, ensuring continuous and safe operation. The more than 250℃ range is designed for the most extreme environments, such as aerospace and specialized industrial applications. These switches are engineered to perform in conditions where other components would fail, providing reliability and safety in critical applications. In aerospace, they are used in engines and other high-temperature areas, where failure is not an option. The ability to operate at such high temperatures makes these switches indispensable in industries where safety and performance are paramount. As technology advances and industries continue to push the limits of what is possible, the demand for high temperature micro switches across all these categories is expected to grow. Manufacturers must continue to innovate and improve their products to meet the increasing demands of their customers, ensuring that these switches remain a vital component in a wide range of applications.

Automotive, Electronic Devices, Household Appliances, Office Equipment, Other in the Global High Temperature Micro Switches Market:

The Global High Temperature Micro Switches Market finds its usage across various sectors, including automotive, electronic devices, household appliances, office equipment, and other industries. In the automotive sector, high temperature micro switches are essential for ensuring the safety and reliability of vehicles. They are used in critical areas such as engine compartments, braking systems, and transmission systems, where they must withstand high temperatures and harsh conditions. These switches help maintain electrical connections, ensuring that vehicles operate safely and efficiently. In electronic devices, high temperature micro switches are used to enhance the durability and performance of products. They are found in devices that generate significant heat during operation, such as computers, gaming consoles, and other consumer electronics. By ensuring reliable operation in high-temperature environments, these switches help extend the lifespan of electronic devices and improve user safety. Household appliances also benefit from high temperature micro switches, as they are used in products like ovens, microwaves, and washing machines. These switches ensure that appliances operate safely and efficiently, even when exposed to high temperatures during regular use. In office equipment, high temperature micro switches are used in printers, copiers, and other devices that generate heat during operation. They help maintain the reliability and performance of office equipment, ensuring that businesses can operate smoothly without interruptions. Other industries, such as aerospace and industrial machinery, also rely on high temperature micro switches for their critical applications. In aerospace, these switches are used in engines and other high-temperature areas, where reliability and safety are crucial. Industrial machinery benefits from these switches by ensuring continuous operation in harsh environments, where heat and heavy-duty operations are common. Overall, the Global High Temperature Micro Switches Market plays a vital role in ensuring the safety, reliability, and performance of products across various industries. As technology continues to advance and industries demand more from their components, the importance of high temperature micro switches is expected to grow, driving innovation and development in this market.

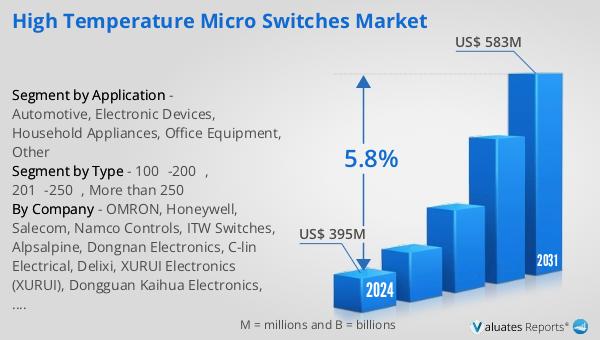

Global High Temperature Micro Switches Market Outlook:

The outlook for the Global High Temperature Micro Switches Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of US$ 395 million in 2024 to approximately US$ 583 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% from 2025 to 2031. This growth is primarily driven by the increasing demand for high-performance switches in critical product segments and diverse end-use applications. As industries such as automotive, electronics, and aerospace continue to evolve, the need for reliable components that can withstand high temperatures becomes more pronounced. However, the market is not without its challenges. Evolving U.S. tariff policies introduce a degree of trade-cost volatility and supply chain uncertainty, which could impact the market dynamics. Companies operating in this space must navigate these challenges while continuing to innovate and meet the stringent requirements of their customers. Despite these hurdles, the overall outlook for the Global High Temperature Micro Switches Market remains positive, with opportunities for growth and development as industries continue to push the boundaries of technology and performance.

| Report Metric | Details |

| Report Name | High Temperature Micro Switches Market |

| Accounted market size in 2024 | US$ 395 million |

| Forecasted market size in 2031 | US$ 583 million |

| CAGR | 5.8% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | OMRON, Honeywell, Salecom, Namco Controls, ITW Switches, Alpsalpine, Dongnan Electronics, C-lin Electrical, Delixi, XURUI Electronics (XURUI), Dongguan Kaihua Electronics, Hua-Jie |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |