What is Global Centrifugal Method Ultrafine Glass Fiber Market?

The Global Centrifugal Method Ultrafine Glass Fiber Market is a specialized segment within the broader glass fiber industry, focusing on the production and application of ultrafine glass fibers using centrifugal methods. These fibers are characterized by their extremely fine diameters, typically ranging from a few micrometers to sub-micrometer levels, which impart unique properties such as high surface area, low density, and excellent thermal and acoustic insulation capabilities. The centrifugal method involves spinning molten glass at high speeds to create these fine fibers, a process that allows for precise control over fiber diameter and uniformity. This market is driven by the increasing demand for advanced materials in various industries, including automotive, construction, electronics, and telecommunications, where these fibers are used for insulation, filtration, and reinforcement purposes. The market's growth is further fueled by technological advancements in manufacturing processes and the rising emphasis on energy efficiency and sustainability, as ultrafine glass fibers contribute to reducing energy consumption and enhancing the performance of end products. As industries continue to seek innovative solutions to meet evolving regulatory standards and consumer expectations, the Global Centrifugal Method Ultrafine Glass Fiber Market is poised for significant expansion.

1-3 μm, 3-5 μm in the Global Centrifugal Method Ultrafine Glass Fiber Market:

In the Global Centrifugal Method Ultrafine Glass Fiber Market, fibers are categorized based on their diameter, with two primary segments being 1-3 μm and 3-5 μm. The 1-3 μm segment represents the finer end of the spectrum, offering superior insulation properties due to the increased surface area and reduced thermal conductivity. These ultrafine fibers are particularly advantageous in applications requiring high-performance thermal and acoustic insulation, such as in the automotive and aerospace industries, where weight reduction and energy efficiency are critical. The finer fibers also find use in advanced filtration systems, where their small diameter allows for the capture of fine particulates, making them ideal for air and liquid filtration applications. On the other hand, the 3-5 μm segment, while slightly coarser, still provides excellent insulation and mechanical properties. These fibers are often used in construction materials, such as insulation panels and roofing materials, where they contribute to improved energy efficiency and structural integrity. The slightly larger diameter of these fibers also makes them suitable for reinforcement applications, where they enhance the mechanical strength and durability of composite materials. Both segments benefit from the centrifugal method's ability to produce fibers with consistent quality and uniformity, ensuring reliable performance across various applications. The choice between 1-3 μm and 3-5 μm fibers depends largely on the specific requirements of the application, with finer fibers being preferred for high-performance insulation and filtration, while coarser fibers are favored for structural and reinforcement purposes. As industries continue to innovate and seek materials that offer a balance of performance, cost-effectiveness, and sustainability, the demand for both 1-3 μm and 3-5 μm centrifugal method ultrafine glass fibers is expected to grow. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the properties of these fibers and exploring new applications. With the increasing focus on energy efficiency and environmental sustainability, ultrafine glass fibers are poised to play a crucial role in the development of next-generation materials and technologies.

Automotive Start-Stop, Grid, UPS & Telecom, Others in the Global Centrifugal Method Ultrafine Glass Fiber Market:

The Global Centrifugal Method Ultrafine Glass Fiber Market finds extensive usage across various sectors, including automotive start-stop systems, grid energy storage, uninterruptible power supplies (UPS), telecommunications, and more. In automotive start-stop systems, ultrafine glass fibers are used in battery separators and insulation materials, contributing to improved energy efficiency and performance. These fibers help reduce the overall weight of the vehicle, enhancing fuel efficiency and reducing emissions. In grid energy storage applications, ultrafine glass fibers are utilized in the insulation of energy storage systems, ensuring optimal thermal management and safety. Their excellent thermal insulation properties help maintain the stability and efficiency of energy storage systems, which is crucial for the reliable operation of power grids. In the UPS and telecommunications sectors, ultrafine glass fibers are used in the insulation of electronic components and systems, providing protection against thermal and acoustic interference. This ensures the reliable operation of critical systems, minimizing downtime and enhancing performance. Additionally, ultrafine glass fibers are used in various other applications, such as filtration systems, where their fine diameter allows for the efficient capture of particulates, and in construction materials, where they contribute to improved energy efficiency and structural integrity. The versatility and performance benefits of ultrafine glass fibers make them an attractive choice for a wide range of applications, driving their demand across multiple industries. As the focus on energy efficiency and sustainability continues to grow, the Global Centrifugal Method Ultrafine Glass Fiber Market is expected to expand, with new applications and innovations emerging to meet the evolving needs of various sectors.

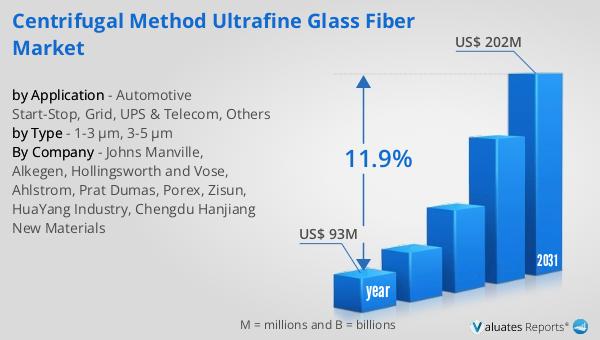

Global Centrifugal Method Ultrafine Glass Fiber Market Outlook:

The global market for Centrifugal Method Ultrafine Glass Fiber was valued at $93 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $202 million by 2031. This growth trajectory reflects a robust compound annual growth rate (CAGR) of 11.9% over the forecast period. This impressive expansion is driven by the increasing demand for high-performance materials across various industries, including automotive, construction, electronics, and telecommunications. The unique properties of ultrafine glass fibers, such as their high surface area, low density, and excellent thermal and acoustic insulation capabilities, make them an attractive choice for a wide range of applications. As industries continue to seek innovative solutions to enhance energy efficiency, reduce emissions, and improve the performance of their products, the demand for centrifugal method ultrafine glass fibers is expected to rise. Additionally, ongoing advancements in manufacturing processes and the development of new applications are likely to further fuel the market's growth. With the increasing emphasis on sustainability and energy efficiency, the Global Centrifugal Method Ultrafine Glass Fiber Market is poised for significant expansion, offering numerous opportunities for innovation and development.

| Report Metric | Details |

| Report Name | Centrifugal Method Ultrafine Glass Fiber Market |

| Accounted market size in year | US$ 93 million |

| Forecasted market size in 2031 | US$ 202 million |

| CAGR | 11.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Johns Manville, Alkegen, Hollingsworth and Vose, Ahlstrom, Prat Dumas, Porex, Zisun, HuaYang Industry, Chengdu Hanjiang New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |