What is Global Plastic Injection Molding Product Market?

The Global Plastic Injection Molding Product Market is a vast and dynamic sector that plays a crucial role in the manufacturing industry worldwide. This market involves the production of plastic parts and products through the injection molding process, a method where molten plastic is injected into a mold to form a specific shape. This technique is highly efficient and versatile, allowing for the mass production of complex and intricate plastic components with high precision and consistency. The market encompasses a wide range of industries, including automotive, packaging, medical, and consumer goods, among others. The demand for plastic injection molding products is driven by the need for lightweight, durable, and cost-effective materials that can be produced at scale. As industries continue to innovate and seek sustainable solutions, the global plastic injection molding market is expected to evolve, incorporating advanced materials and technologies to meet the changing needs of consumers and businesses alike. This market's growth is also influenced by factors such as technological advancements, environmental regulations, and the increasing adoption of plastic products in various applications. Overall, the Global Plastic Injection Molding Product Market is a vital component of the global economy, providing essential products and solutions across multiple sectors.

Thermoplastic, Thermoset Plastic in the Global Plastic Injection Molding Product Market:

Thermoplastics and thermoset plastics are two primary categories of materials used in the Global Plastic Injection Molding Product Market, each with distinct properties and applications. Thermoplastics are polymers that become pliable or moldable at a specific elevated temperature and solidify upon cooling. This characteristic allows them to be reshaped and recycled multiple times without significant degradation, making them highly versatile and popular in various industries. Common types of thermoplastics used in injection molding include polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC). These materials are favored for their durability, lightweight nature, and resistance to impact and chemicals, making them ideal for applications in automotive parts, packaging, and consumer goods. On the other hand, thermoset plastics are polymers that irreversibly cure or set when exposed to heat or chemical reactions. Once set, they cannot be remelted or reshaped, which gives them excellent thermal stability and resistance to deformation under high temperatures. This makes thermoset plastics suitable for applications requiring high strength and rigidity, such as electrical components, automotive parts, and industrial machinery. Common thermoset plastics include epoxy, phenolic, and melamine resins. The choice between thermoplastic and thermoset plastics in injection molding depends on the specific requirements of the application, such as mechanical properties, thermal resistance, and cost considerations. In the Global Plastic Injection Molding Product Market, the use of these materials is driven by the need for efficient production processes, material performance, and sustainability. As industries continue to innovate and develop new products, the demand for both thermoplastic and thermoset plastics is expected to grow, with advancements in material science and technology playing a crucial role in shaping the future of the market. The ability to produce complex and high-quality plastic components efficiently and cost-effectively makes injection molding a preferred manufacturing method across various sectors. Furthermore, the increasing focus on sustainability and environmental impact is driving the development of bio-based and recyclable plastics, which are expected to gain traction in the market. Overall, the Global Plastic Injection Molding Product Market is characterized by a diverse range of materials and applications, with thermoplastics and thermoset plastics playing a pivotal role in meeting the evolving needs of industries worldwide.

Automotive Industry, Packaging Industry, Medical Equipment, Food Manufacturing, Others in the Global Plastic Injection Molding Product Market:

The Global Plastic Injection Molding Product Market finds extensive usage across various industries, each leveraging the unique properties of plastic components to enhance their products and processes. In the automotive industry, plastic injection molding is used to produce a wide range of parts, from interior components like dashboards and door panels to exterior elements such as bumpers and grilles. The lightweight nature of plastics helps improve fuel efficiency and reduce emissions, while their durability and design flexibility allow for innovative and aesthetically pleasing designs. In the packaging industry, plastic injection molding is essential for creating containers, caps, and closures that are lightweight, durable, and cost-effective. The ability to produce complex shapes and designs with precision makes injection molding ideal for packaging solutions that require airtight seals and tamper-proof features. In the medical equipment sector, plastic injection molding is used to manufacture a variety of components, including syringes, vials, and surgical instruments. The biocompatibility and sterility of medical-grade plastics make them suitable for use in healthcare applications, where safety and hygiene are paramount. In food manufacturing, plastic injection molding is employed to produce food containers, utensils, and packaging materials that are safe for food contact and help preserve freshness. The versatility of plastics allows for the creation of innovative packaging solutions that enhance convenience and extend shelf life. Beyond these industries, plastic injection molding is also used in electronics, consumer goods, and construction, among others. The ability to produce high-quality, cost-effective plastic components with precision and efficiency makes injection molding a preferred manufacturing method across diverse sectors. As industries continue to innovate and seek sustainable solutions, the Global Plastic Injection Molding Product Market is expected to evolve, incorporating advanced materials and technologies to meet the changing needs of consumers and businesses alike.

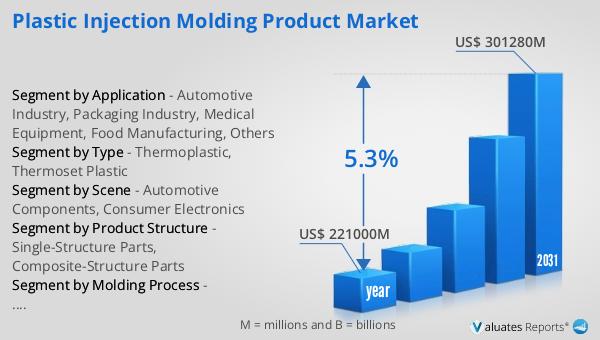

Global Plastic Injection Molding Product Market Outlook:

The global market for Plastic Injection Molding Products was valued at $221 billion in 2024, and it is anticipated to expand to a revised size of $301.28 billion by 2031, reflecting a compound annual growth rate (CAGR) of 5.3% over the forecast period. This growth trajectory underscores the increasing demand for plastic injection molding products across various industries, driven by the need for lightweight, durable, and cost-effective materials. The market's expansion is also influenced by technological advancements, environmental regulations, and the growing adoption of plastic products in diverse applications. As industries continue to innovate and develop new products, the demand for plastic injection molding is expected to rise, with advancements in material science and technology playing a crucial role in shaping the future of the market. The ability to produce complex and high-quality plastic components efficiently and cost-effectively makes injection molding a preferred manufacturing method across multiple sectors. Furthermore, the increasing focus on sustainability and environmental impact is driving the development of bio-based and recyclable plastics, which are expected to gain traction in the market. Overall, the Global Plastic Injection Molding Product Market is characterized by a diverse range of materials and applications, with thermoplastics and thermoset plastics playing a pivotal role in meeting the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Plastic Injection Molding Product Market |

| Accounted market size in year | US$ 221000 million |

| Forecasted market size in 2031 | US$ 301280 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Scene |

|

| Segment by Molding Process |

|

| Segment by Product Structure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Chukoh Chemical Industries, HTI Plastics, SABIC, Chevron Phillips Chemical, NOVA Chemicals, Vaupell, Universal Plastic Mold, PTI Engineered Plastics, Eco Molding Co., Ltd., FOW Mould |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |